Okay, so the first try at closing up the elevator tip fairing didn't turn out so well. I forgot to take a picture, but basically the fiberglass had nothing to adhere to (the lead was coated with tape to prevent sticking) so it was very wavy and uneven. Also, since I only used three plies of 1 oz cloth it was very flimsy.

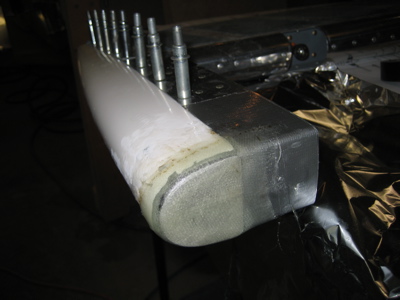

One of the nice things about fiberglass is that if you screw up you can usually grind off your mistake and try again. This time I'm going to try using a piece of aluminum to provide the structural strength, and the fiberglass will just be there to hold it all together. I made a forward bulkhead out of some scrap alclad (0.040" I think), scuffed it up so the epoxy would stick, and temporarily attached it to the counterweight with double-sided tape.

Then I laid up three layers of 5 oz cloth, with a single layer of 1 oz cloth over the top to help fill in the weave. We'll see how this turns out.

I must say, the new style of elevator counterweight is a real pain. The old arrangement seems like it would allow you to spend a lot less time messing around with fiberglass to get the tip fairing to come out just right. But what do I know…

Back to the rudder, I mixed up another batch of micro and applied it here and there. This photo is kind of hard to interpret, but what you're looking at is a glob of micro applied to the front face of the rudder cap, with a piece of scrap alclad (covered with duct tape to make it non-stick) taped in place to make it cure with a nice smooth, even surface.

My cat wanted to help write this entry: