After putting some protective tape over the end of the slider frame latch tube, I flipped the canopy over and laid the frame inside.

The goal is to get the frame aligned on the previously marked centerline, in the fore-aft location that results in the best fit along the center spine tube. Then you mark the location of the latch tube and drill a 5/8" hole. I got as far as marking the hole location, but the temperature didn't get up nearly as high as I thought it would, so I had to give up on drilling/trimming the canopy for another day. Bah.

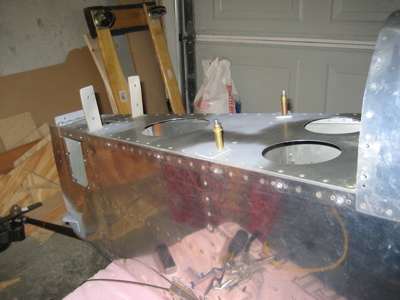

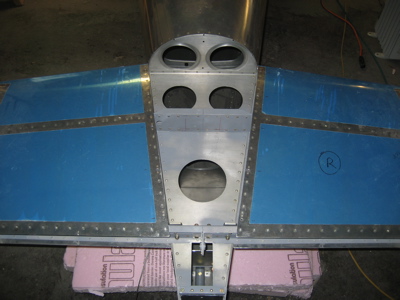

In an effort to find something else to do, I dug up the subpanel pieces, dimpled the top rib flanges, and clecoed the whole works into the fuselage.

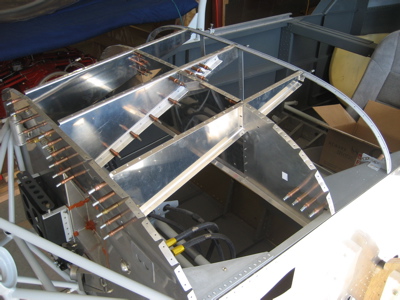

Then I deburred the forward top skin, which I hadn't yet bothered to do. I dimpled where I could reach along the edges, leaving the holes along the firewall undimpled for now – the cowling attach hinges still need to be match-drilled there, much further down the road. Then I packed up the skin and drove over to John's to use my DRDT to dimple the rest of the skin. Not a very efficient use of building time, but it felt like a good day to spend a couple hours driving.

Somewhere in there I did some more filler work on the left horizontal stabilizer tip fairing. I've had this clamp for at least ten years and I'm pretty sure this is the first time I've ever used it.

Also, I stopped at Lowe's and tried to buy a new belt sander, but they were out. Bah.