I cut the left and right C-666 aft canopy skirts out of the provided 0.032" material, using the pre-drawn outlines as a guide (though I left plenty of extra material on all sides). Since I know people often end up making multiple sets of these before they come out right, I made a posterboard template before doing anything else.

I built this roller out of wood in the hopes that it would do a superior job of bending the skirts to fit the canopy, but in the end it was just as easy to bend them by hand over my knee. This was a fun little side project though. Here I'm rolling a curve into a piece of scrap:

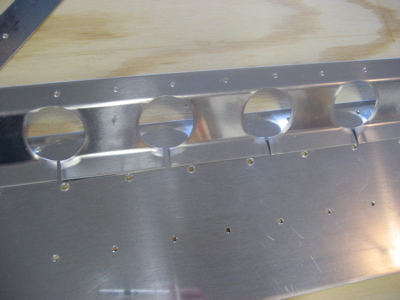

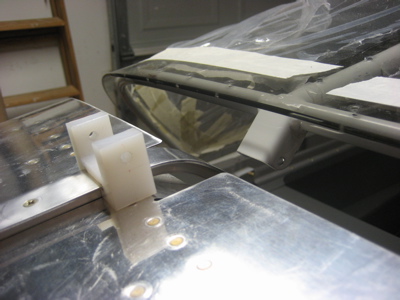

In an attempt to ensure a better fit of the aft skirts, I made and inserted 1/8" spacers between the fuselage longerons and the brackets that hold the rear canopy pin anchor blocks. I'll fit the skirts as best I can with these spacers in place – then when I remove them, the fit should improve a little bit more.

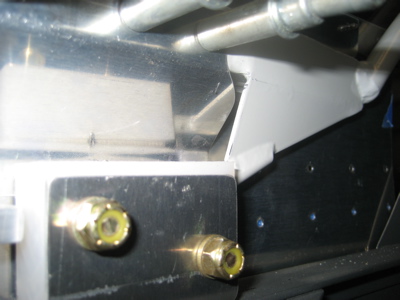

Since the spacers raised the aft end of the canopy, I had to disconnect the slider block from the frame in order to get the canopy shut:

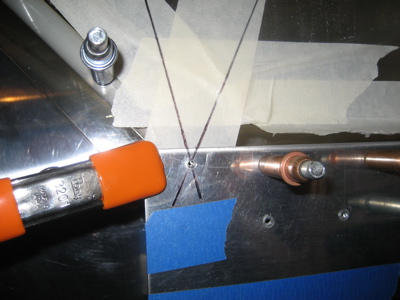

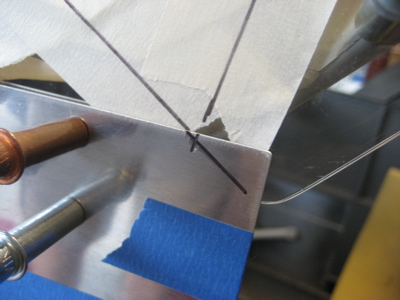

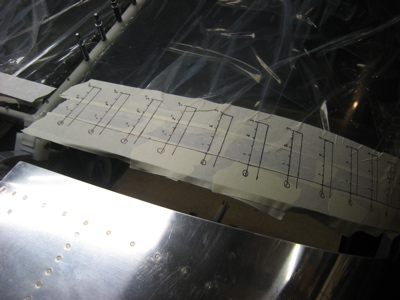

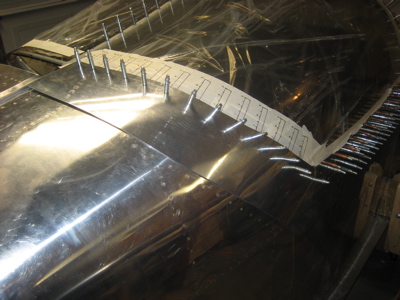

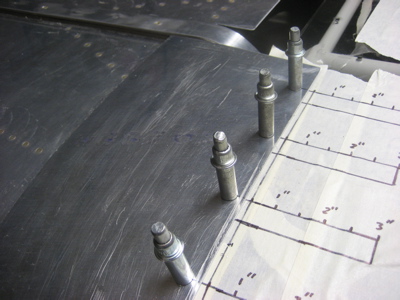

I order to locate the pre-existing holes in the canopy while fitting the skirts, I put down some masking tape and drew a bunch of guide lines using the method shown in the Orndorff video (i.e. line up a ruler with the hole, then draw an outline of it so you can find the hole later).

Mary came down and helped hold the right skirt in place while I marked and drilled the holes.

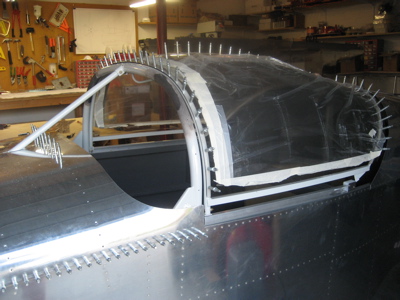

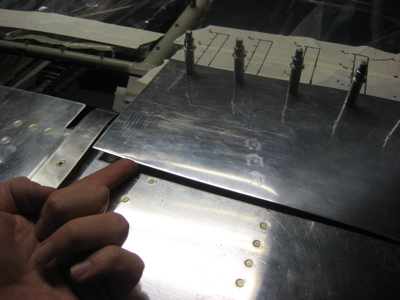

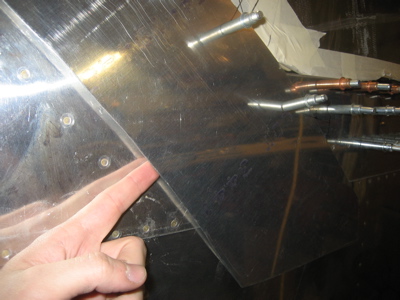

As I expected, there's a pretty big gap at the top…

…and also at the bottom. I know now that this is due to less than optimal positioning and shaping of the rear canopy bow at the outset of canopy construction, but in my defense it's hard to know exactly how to shape an RV canopy frame until you've tried to fit a set of RV canopy skirts.

Once the pilot holes were drilled, I took the skirt off the plane, trimmed and smoothed the forward and aft edges, and reinstalled it.

Then I fitted and trimmed the left aft skirt, same as the first. It also has similar fit issues.

Here's another problem for later – the C-792 piece that covers the slider block is shorter than my canopy skirts. Oh well, I'll deal with the fit problems first.

Here's another view of the problem areas on top. I ordered a metal shrinker from Avery in the hopes that I can work the aluminum to get it to lay down on the fuselage properly, so hopefully this will be a "before" picture.

If all else fails, I'll throw the aluminum skirts away and make properly-fitting ones out of fiberglass, but I want to try doing it in metal first.