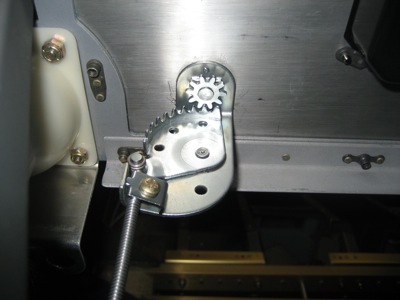

I have been thinking for a while about what kind of mechanism to use for the cabin heat control. Although most airplanes use some kind of plunger-like Bowden cable for this purpose, I thought it would be kind of neat touch to use a rotary knob instead. Through VAF I found a gear control with cable that I thought might work, so I ordered one to try out:

It's an automotive heater control, which translates 270° of knob rotation into a couple inches of cable movement. For reference, I believe this is made by Evans Tempcon, part number RV218456. As far as I can tell, it seems to be designed for an old Grumman mail truck, and since Grumman also made a bunch of great airplanes, it's practically an aviation part already!

The cable sheath that came with it was way too thick, but I was able to replace it with the outer sheath from a spare Bowden cable I happened to have on hand. I also replaced the sheet metal screw holding the cable clip with a machine screw and nyloc nut instead. After some experimentation I decided that it might work, so I mounted it in the lower outboard corner on the passenger side:

On the crew-facing side of the panel, the knob control is held on with a nut and lockwasher (salvaged from the junk bin at work). I also drilled and tapped a hole through the panel and the steel body of the gear assembly, for a 4-40 screw to keep it from rotating.

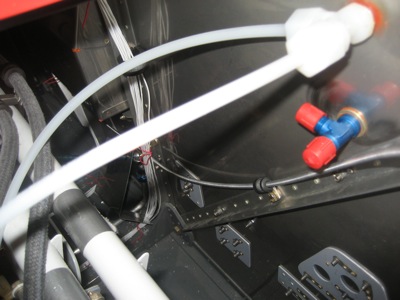

The cable goes forward from the panel, is secured to the bottom of the subpanel with an adel clamp, and then heads uphill and outboard towards the corner of the firewall:

At its apogee, the cable is affixed to the fuel vent line with a pair of adel clamps. This is about the only clamping arrangement I could come up with that didn't involve remaking the aluminum line; it's just here to keep the cable from wobbling around, not supporting any actual load.

From there the cable goes down one of the firewall stiffeners to the heat box area. To hold this adel clamp, I used a slightly longer bolt into one of the nutplates that attaches the battery box to the firewall.

I drilled a hole in the upright firewall stiffener and ran the cable sheath through it. The heat box control arm is attached with a cable wire nut. The amount of cable travel is just about perfect for this application.

Back at the panel end, I put on a knob I got from McMaster-Carr, and whipped up a little placard in DeltaCAD (just a paper printout of it in this photo). I'll add this to the list of placards I need to have engraved or printed on vinyl for the finished panel.

Here's a wider view of the right side of the panel:

I'm pretty pleased with how this turned out. I'm trying to provide an automotive-like environment for passenger comfort, and having a heat control that makes sense to non-pilots will certainly help.