I finally got sick of being embarrassed about a few of the rivets in the F-705 bulkhead – other builders will know exactly which ones I'm talking about – so I drilled them out and replaced the ones that are impossible to properly buck with AN525 structural screws.

View from the aft side. I also drilled out and replaced the rivets whose shop heads are hidden under the canopy decks, because I didn't have a tungsten bucking bar last time I tried to set these and they were kind of ugly. This time they were relatively easy to redo using two pounds of element 74 and a double-offset rivet set.

A quick spritz of paint and you can't even see the screw head unless you know right where to look.

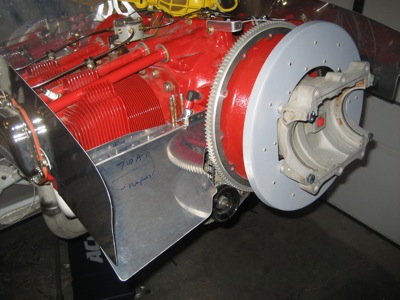

Then it was back to working on the baffles… except wait, it looks like one of the screw holes in the engine case isn't tapped deep enough. Maybe I can just force the screw in there?

Nope! Big mistake. Twisted the head right off, and now there's a broken screw stuck in the engine case. In the very expensive engine case.

What to do? Over the course of half an hour I went through all five stages of grief:

- Denial – "That hole can't be very important, and I can still make the baffles work without it, right?" (no)

- Anger – "Stupid screw, you suck for not being stronger! Stupid hole, you suck for not having enough threads!"

- Barganing – "Maybe I can build some kind of brace to transfer the load to a different hole?" (no)

- Depression – "I should just chop this thing into bits and push them out to the curb and let them be hauled to the dump."

- Acceptance, starting by very carefully drillling through the center of the bolt:

…then going to the store to buy a bolt extractor:

The screw broke in half and I had to re-drill it and restart the extractor, but I got it all out!

Whew, what a relief:

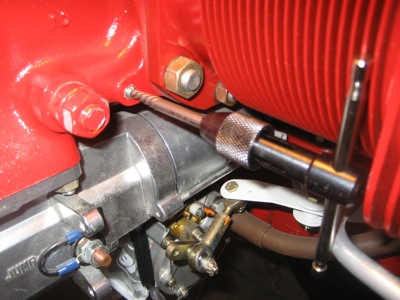

Then I did what I should have done in the first place, which was to tap it about 1/8" inch deeper so the screw can be fully inserted:

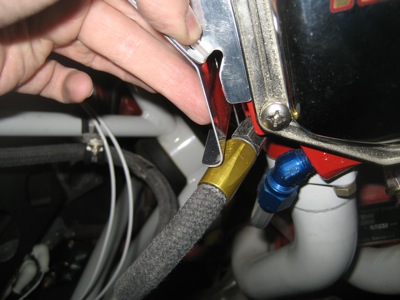

Now it can be threaded in far enough to hold this bracket in place. No lockwasher yet since this screw will be removed and replaced many times before the baffles are done.

Very expensive engine not ruined after all. This whole episode really took the wind out of my sails, but I sure earned this:

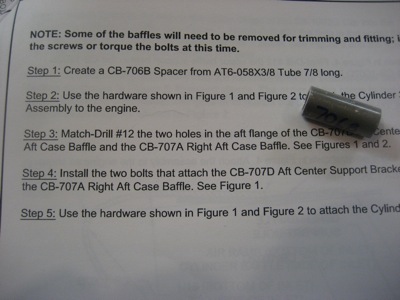

I also spent many hours this weekend researching stuff about the baffles, and I think I almost know what to do next. Now that the Great Screw Disaster is resolved, baffle work will resume next time…