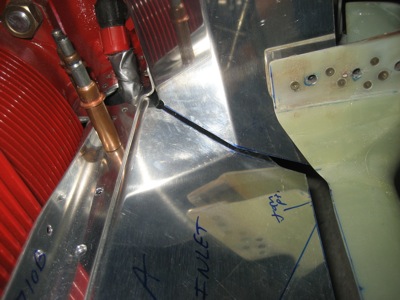

Well, this is a fine mess… there's no room on the left inlet ramp for the brackets that are supposed to attach to the left crankcase baffle:

Adding insult to injury, I accidentally trimmed off too much of the crankcase baffle while I was trying to get it to fit, resulting in a too-large gap behind the cowl inlet:

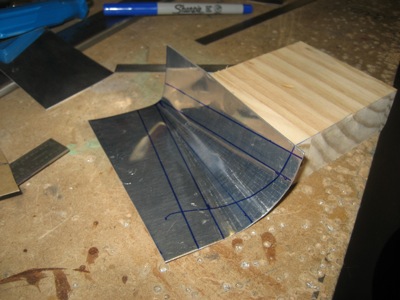

I spent a day scratching my head and testing various ideas to make this all work, before I finally came up with something that I was happy with. I started by making two brackets and a filler piece:

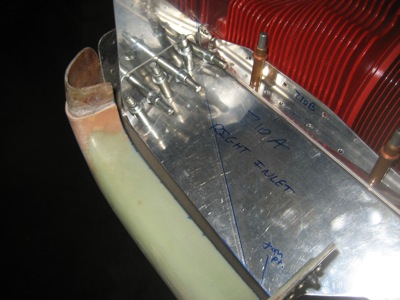

Here's how the two brackets are attached to the inlet ramp. Each one picks up one of the rivets in the other bracket that runs longitudinally on the bottom side. You can also kind of see how I ground away the edge of the air filter retaining ring to make it clear the crankcase baffle.

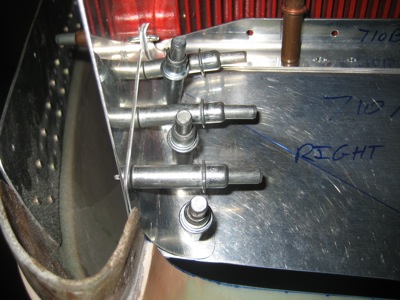

The funny-shaped bracket tucks under the baffle and attaches on the back side:

Another view of the same area:

The filler piece rivets to the baffle and erases my trimming mistake:

It all basically works together, and I verified that there is still just enough room to remove and reinstall the air filter and bracket. Stupid air filter, making things entirely more complicated than necessary, again.