Had a bit of a work interruption recently due to a painful injury that knocked me off my game for a couple weeks, but I'm back on top now. So, remember those great-looking cowl intake duct closeouts I made last time? Yeah, about that… it seems that it would have been a good idea to check the fit with the flywheel installed before I got all crazy with the fiberglass. Grinding away a week of work was no fun at all.

I traced the line of the crankcase baffles onto the cowl so I'd know where to build the shape back up:

With the inboard ends of the inlet ramps cut further back, the cowl fits over the engine like it's supposed to:

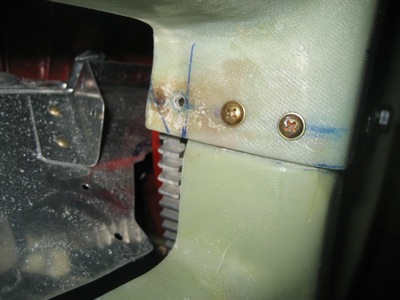

Here's another problem area I've been putting off dealing with. I had to cut the lower cowl farther forward in order to allow it to clear the engine air filter when it's being installed and removed, and in doing so I lost space for the third attachment screw.

I cut the upper cowl to match and sanded the edge straight. For now I'll just live with only two screws on each side of the spinner here. If it causes problems down the road, I'll come up with a fix. In retrospect, it was a bad idea to follow the plans and drill all three holes early on… I should have drilled only a single hole at the very front, and left the others for after I had the cowl trimmed to fit the baffles.

At least the inlet ducts are fine at the outboard ends. I trimmed the forward cylinder baffles to fit the inlet ramps using the paper clip method.

I built up the new inlet duct closeout shapes I wanted using floral foam. This time made sure to leave clearance around the flywheel, and to allow a more natural transition of the crankcase baffles as they run across the inlet ducts and up to the apex of the cowl.

I laid up three plies of glass over the foam:

Then I followed up with the usual sand-and-fill process. Once again, this looks like hell, but it's fairly smooth to the touch.

Here's a view looking inside the cowl to show just how close the flywheel comes to the cowl and inlet ducts. There's a gap of about 1/2" all the way around, now that I properly shaped the fiberglass to fit.

Now I guess I'm back where I was a month ago, except this time the cowl fits properly. I guess that's progress, of a sort. Oh well – if this was easy, everybody would be doing it.