Three projects in one post today, for reasons that will become clear…

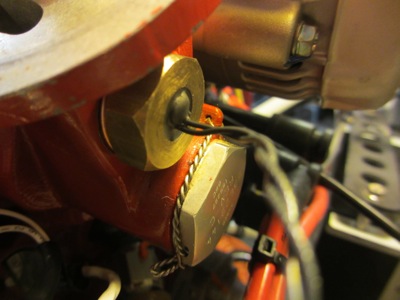

First, I fabricated the business end of the magneto P-lead. This connects to a switch in the cockpit that operates in reverse of the normal fashion. When the switch is open, the magneto can operate and generate its own sparks. When the switch is closed, the magneto is grounded and can't fire. For historical reasons unknown to me, the terminals on the magneto to which you connect this pair of wires are called "GND" and "P", hence "P-lead".

The open hole partially visible in the center of this image is where the oil temperature sensor goes. The hex-shaped thing below it is the exterior portion of the Vernatherm, which is a fancy trade name for "thermostat". The stuff at the top of this picture is where the oil filter threads on. Sorry for the terrible photo, this area is really close to the firewall so I can barely get my camera back there, let alone see it when I'm trying to work on it.

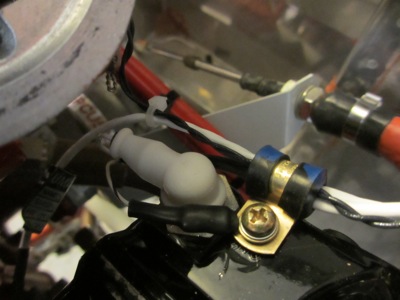

This is what the oil temp probe looks like. I crimped on a connector so I can replace it more easily in the future if I have to.

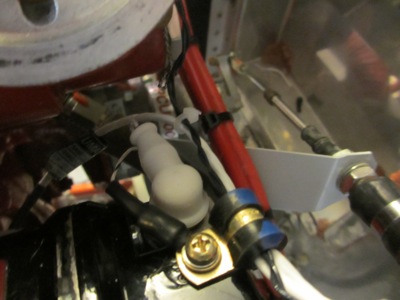

Oil temp probe installed with a new AN900 copper crush gasket. Crush gaskets are kind of interesting since you tighten them by turning to a specified angle rather than using a torque wrench. Since the hole uses a 5/8-18 thread, this gets tightened to 135° beyond finger-tight.

To install the RPM sender on the magneto, I had to remove the mag from the engine. Ugh! Wish I'd thought ahead a little more. Oh well.

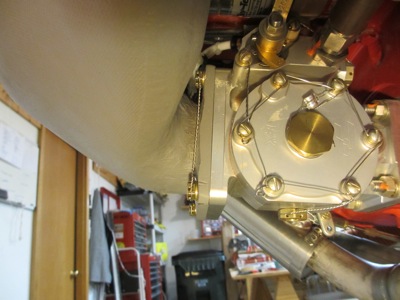

The RPM sender threads into an unused vent hole on the mag, which is usually capped with a hex-shaped plug.

RPM sender installed in mag, using blue loctite and tightened to the specified torque. The P-lead and ground screw hole are visible at left.

Mag reinstalled… I used the timing pin and attempted to get it timed properly, although I will revisit the timing again for both the magneto and P-mag at some point in the future.

Now here is why I'm covering three otherwise unrelated wiring projects in the same post. All of these wires – P-lead, oil temp, and RPM – pass through the same area on the back of the engine, and all of them need to be supported so they don't vibrate and eventually break. The most convenient place to anchor these wires is actually the hole for the P-lead ground screw itself.

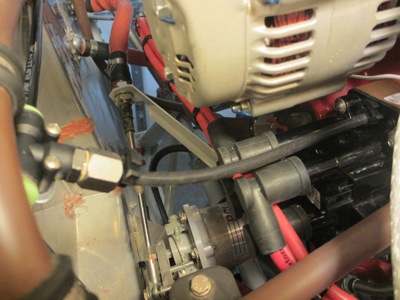

So what you're looking at here is the back of the magneto, with an adel clamp affixed to the hole that normally just gets a ground terminal; the ring terminal for the ground lead is between the screw head and the clamp. The other P-lead conductor loops around and attaches to the magneto "P" terminal, hidden under a rubber boot. Meanwhile, the wires for the oil temperature probe and the RPM sender pass through from left to right and are restrained by the clamp.

Again, sorry for the photo quality… this area is hard to see, hard to work on, and hard to photograph.

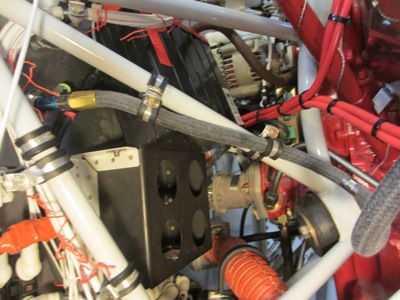

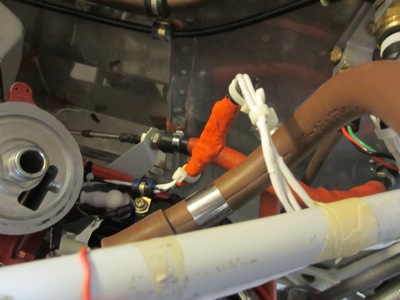

Moving upwards, the wire bundle loops around an oil hose and then attaches to the engine mount. Where there is currently masking tape holding things temporarily, I will eventually put a pair of adel clamps to grab onto this wire bundle. As with the bus current sensors, I used silicone tape around the connector for the oil temp sensor to keep water out.

Same area, this time with the oil filter installed:

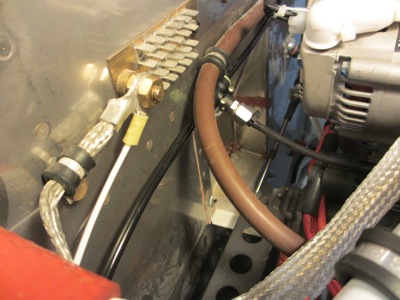

Another glob of silicone tape to protect the connector for the RPM sensor, and then all three sets of wires pass through the firewall:

By the way, I did not think of this clever wiring trick myself – I got it from this VAF post.