The last remaining wiring task forward of the firewall is some kind of power connection for use on the ground. There are two schools of thought on how this ought to be done – at minimum, a ground power connection should be capable of charging the aircraft battery and perhaps powering the important avionics during maintenance, but some folks also like to be able to jump-start their airplane from a power cart in the event of a dead battery. The problem I found with the latter approach is that the connector required to support starter cranking current is expensive and huge, and there's not a great place to mount it without cutting into important fuselage structure. I also decided that in my electrically-dependent airplane, it wouldn't be wise to get a jump-start and then immediately go flying with a sick battery. So, my ground power circuit will be capable of connecting a battery charger or a small power supply to run the avionics, but to save weight and complexity it won't be able to crank the engine.

For the ground power connection I needed a connector that's lightweight and rugged but still able to handle plenty of current. I selected an Anderson Powerpole connector, which is widely used in the amateur radio field for high-current applications. These connectors are kind of cool, in that multiple poles lock together in with dovetails in a variety of orientations, allowing you to create any kind of custom connector you want. For this application, though, I stuck with the de facto standard arrangement.

Of course, what's a new connector without a new crimper to go with it? I couldn't figure out how to buy just the dies for these connectors, at least not ones that would fit any of my existing crimper frames, so I ended up with a whole new crimper just for a couple connections. Oh well, as a tool junkie I can't complain too loudly.

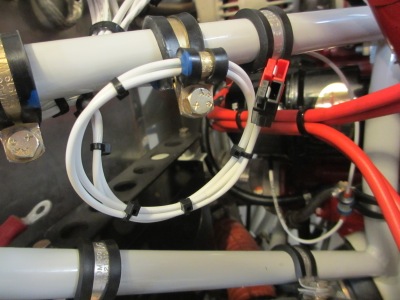

The ground power connector is secured near the oil dipstick, so that it will be possible to access it through the oil door without removing the cowl. The wiring is 12-gauge, which will be good for up to 15 amps. The black side of the connector finds its way to the main ground block, and the red side connects to the always-hot battery bus through a 15-amp fuse.

Another closeup view… The wiring is tied off and clamped in such a way that nothing can flop around and abrade itself or anything nearby. I left a decent service loop in case I decide I need to relocate the connector later on.

I fabricated a short Powerpole harness for my bench power supply, plus a ten-foot extension cord with Powerpole connectors on both ends. I plugged it all in and verified it works to power up the panel, so that's that. I'm sure this will get a lot of use, both during construction and afterwards.