I decided on a new plan of attack for the elevator caps – I'll attach them permanently, but I'll make them look like they can come off. Then at least all the fairings on the tail of the airplane will have a consistent look, which is important if you're obsessive like me. First I rounded off the forward edges of the lead counterweight with a file, then I match drilled the untouched elevator cap and installed nutplates and reinforcement strips:

The two nutplates at the aft end are very close together. If I hadn't been forced to use the prepunched holes I would have staggered these a bit to avoid interference, as I did with the aftmost rivets holding the aluminum strips to the fairing. As it is I had to cut down some screws to keep one screw from trying to push the other one out.

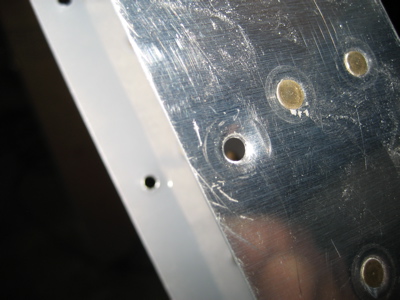

Here's another thing that I'll do differently on my next airplane – when you dimple the attachment holes for the elevator caps, the rib flange gets between the dimple die and the skin and all your dimples end up with this little crease on the inboard side. You won't be able to see this once it's all painted, but if I'd known this I would have at least match drilled the fairings and dimpled these holes before riveting the elevators together.

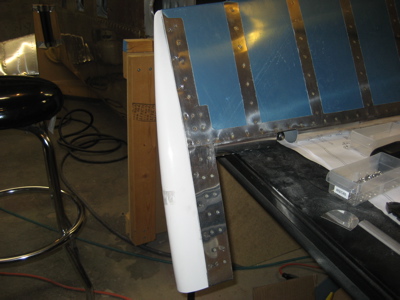

Here's a test fit to make sure all the nutplates and holes are lined up:

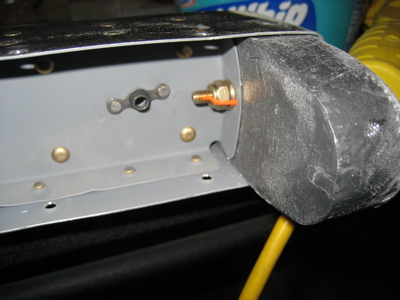

I riveted a #10 nutplate to the outboard side of the counterbalance arm, using the 3/16" tooling hole that was already there. The reason for putting a nutplate here is that I can use it to bolt on a wide-area washer or two if it turns out that my elevator needs a little bit more weight up front… call it balancing insurance. Also, this photo is proof that I checked the torque on the outboard counterweight bolt on the right elevator – it will be inaccessable once the fairing is on for good.

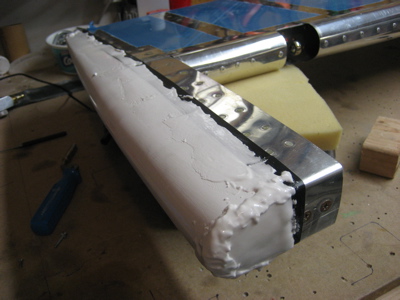

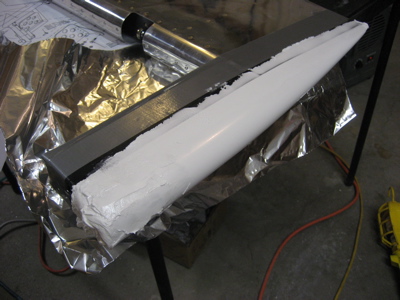

Okay, I wasn't able to take pictures of how I performed the next series of steps, but I'll describe it and show the result. I mixed up a slurry of epoxy and flox, and applied a thick layer between the lead counterweight and the inside face of the tip fairing. This should glue the fairing to the lead and also fill in the gaps between them. Then I put in all the screws, and covered the edge of the skin with a layer of electrical tape. Next I mixed up a big batch of epoxy and micro, and used it to fill the gap between the skin and fairing on both sides of the elevator. I also applied a generous helping of filler to cover over the forward face of the counterweight, and the corners with the fairing and the counterweight come together. Most of it will get sanded off later, but this should hopefully provide the basis for a nice looking fairing closeout.

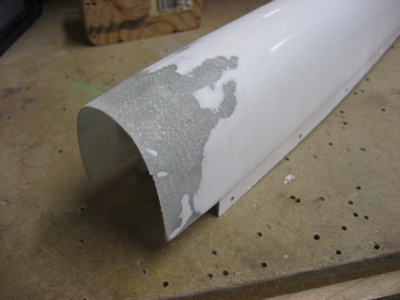

After all of the above was finished, I figured the right elevator would be out of commission for the rest of the day before the goo was cured, so I started thinking about the left elevator. It turns out that a replacement elevator cap is thirty bucks from Van's, so instead of throwing away the one I'd previously tried to put glass on, I spend some time sanding off my mistakes and restoring it to nearly-new condition.

Then I performed the same series of steps – match drilling, installing nutplates, and so forth. This photo is proof that I installed the spare nutplate and checked the torque on the inaccessable bolt on the left elevator

After all that (a couple hours of work) the left elevator cap got the same filler treatment:

Once both elevators are dry I'll start sanding them down. For now, though, I'm sick of composites.