Fuel-injected Lycoming engines can sometimes experience a phenomenon wherein excess fuel drips down the induction tubes and pools in the intake manifold after shutdown. This can be a problem, since it could cause a troublesome fire during the next start. To alleviate this, you install a simple little one-way check valve in the bottom of the intake, which lets the fuel drip out of the engine onto the ground. For whatever reason, this item is colloquially referred to as a sniffle valve.

Here's a bad picture of the one I bought from Airflow Performance for a few bucks – it's basically just a normal AN fitting that's been drilled out and had a ball bearing and retainer clip inserted. Reduced pressure inside the manifold causes the ball to be sucked up to close the valve when the engine is running, but it drops down and lets the fuel drip out when the engine is shut down.

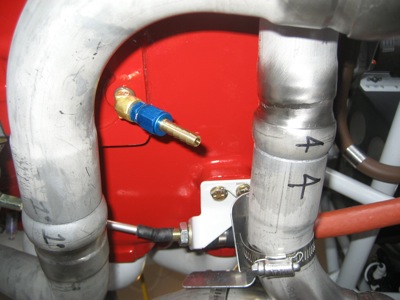

I knew from previous reading that the sniffle valve is too close to the exhaust pipes on an IO-360 with horizontal induction, so I installed it in a 45-degree brass street elbow to clear the pipes. The exact orientation of the valve is said not to matter much, as long as the ball is free to drop when the airplane is at rest. I also attached a 1/4" hose barb to 1/4" AN flare adapter, similar to the one I used for the fuel pump drain line.

I ran another 1/4" aluminum line from the firewall up to the sniffle valve, using a length of 1/4" rubber fuel hose as a flexible coupling. The forward (engine) end of the aluminum tube is ever so slightly flared to give the clamps something to work with – using a real beading tool would have been best, but I can't afford one and this is not a critical application. The aft end of the drain tube is attached to the firewall flange with an adel clamp, just like its twin the fuel drain line.

One more of the million firewall forward tasks is complete… and with that, I'm off to try and make a dent in the beer and ice cream still left over from Saturday's party.