Continuing work on the pitot system, I got the pitot line run inside the wing today. While some folks use a short length of aluminum tubing and then transition to plastic line, I chose to use aluminum throughout since I'm comfortable working with it and I know it won't ever go brittle and fall apart on me (a problem I had with the pitot/static lines in my last RV!)

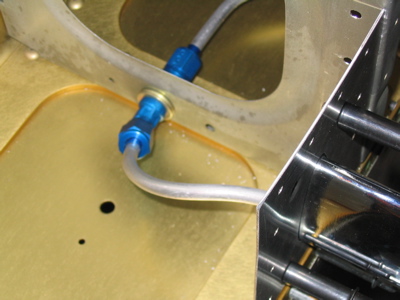

The pitot tube itself has a short and twisty length of tubing attached to it, although not so twisty that it can't be inserted through the pitot mast from the bottom up. This will allow the short aluminum tube to be disconnected just above the pitot mast, and the pitot tube can then be removed for service. The pitot mast doesn't have to be removed in order to remove the pitot tube.

Inside the wing, the short length of tubing connects to a 45° bulkhead fitting:

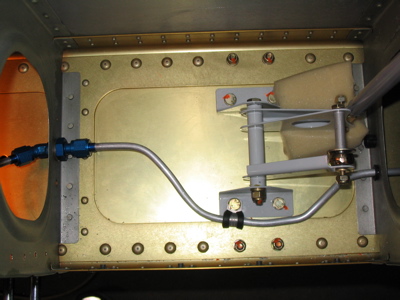

Then another length of tubing runs all the way to the wing root, first bending down and behind the aileron bellcrank and then passing through a snap bushing in the next rib. An Adel clamp on one of the bellcrank bolts (one size longer to compensate for the extra stuff it's holding) anchors the tubing firmly in place. Note that the short length of tubing between the bulkhead fitting and the pitot tube can be reached easily through the access panel that will eventually cover all this.

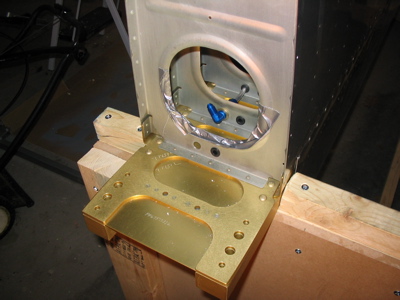

At the root end, I put a 90° bulkhead fitting in the rib that's just outboard of the root rib:

My thinking here was that there probably wouldn't be enough space between the root rib and the fuselage to get the fuselage side of the pitot line connected straight to the root rib – not to mention the placement of these snap bushings causes the pitot line to dead-end right into the center section bulkhead – so I'll bring in flexible tubing from under the pilot's seat, through the second lightening hole aft of the spar, and onto this fitting.

And yes, it was a pain to get all that tubing in there, especially the process of flaring the inboard end.

P.S. The duct tape is to protect the primer on the aileron pushrod from getting scratched; it's not structural.