Today's job was the center section cover. Here it is being test fitted, along with the access plate that screws to it:

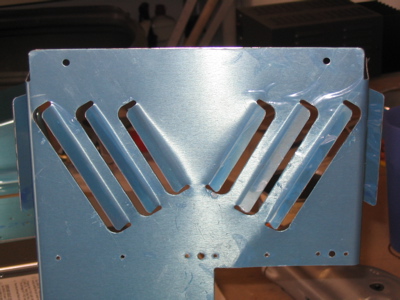

Here the heat baffle is being fitted for riveting. The hot air from the heat muff passes through the firewall behind the upright part of the center section cover, and this piece keeps the hot air from going down inside the tunnel – it's forced out through the louvers instead. I decided not to prime any of these parts, since they're removable.

I bent the louvers outward as directed by the plans. Actually I used a different technique than the plans call for – they say to clamp a piece of angle across the bend line and use your fingers, but I found that this material was too thick to make good looking bends by hand. So, I clamped a piece of angle across either face of the bend line (important to prevent a sloppy bend) and grabbed the louver with my hand seamer to make the bends. It worked pretty well.

Then it was an eternity of deburring – the center section cover has a lot of edges that need to be smoothed.

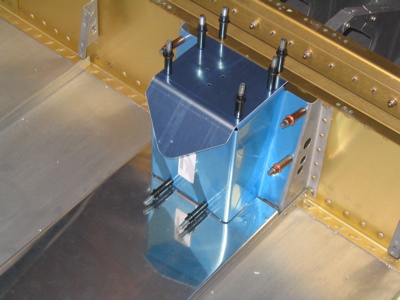

Here's a trial fit of the fuel selector housing. There is a small (3/16") gap between the fuel selector cover and the aft edge of the center section cover, but I couldn't move the center section cover any further aft and still get the flange that attaches it to the selector housing to line up. This will probably be invisible anyway.

I know the fuel selector mounting plate is on upside down in this photo – I'm going to cut off the bent tab anyway since I have electric elevator trim and don't need it to mount the manual trim knob.

The plans call for 15/16" spacing between the floor and the center section cover, and suggest using a "simple wooden spacer". I didn't have any wood of the proper size, but I found these nuts that had the exact right outside dimension. Good enough.

I lined everything up and drilled the holes where the center section cover gets attached to the floor stiffener with screws.

Oh, rats – I somehow let things get out of whack when I drilled the center section cover to the stainless firewall recess, and these two holes ended up in the wrong spot. You can just barely see in the photo that the holes in the recess are about 1/4" too high. Dang. I thought about ordering a new firewall recess piece, but I didn't want to pay twenty-five bucks just to fix two misdrilled holes. Hmm…

What I did instead was fabricate and rivet this trim strip to the top of the center section cover, and back drilled into it through the misplaced holes in the firewall recess. Now everything lines up, and this will be invisible once it's all painted. Problem solved. The rivets that attach the strip to the cover and squashed extra flat so they won't interfere with the lower edge of the firewall recess; this isn't structural so it won't matter.