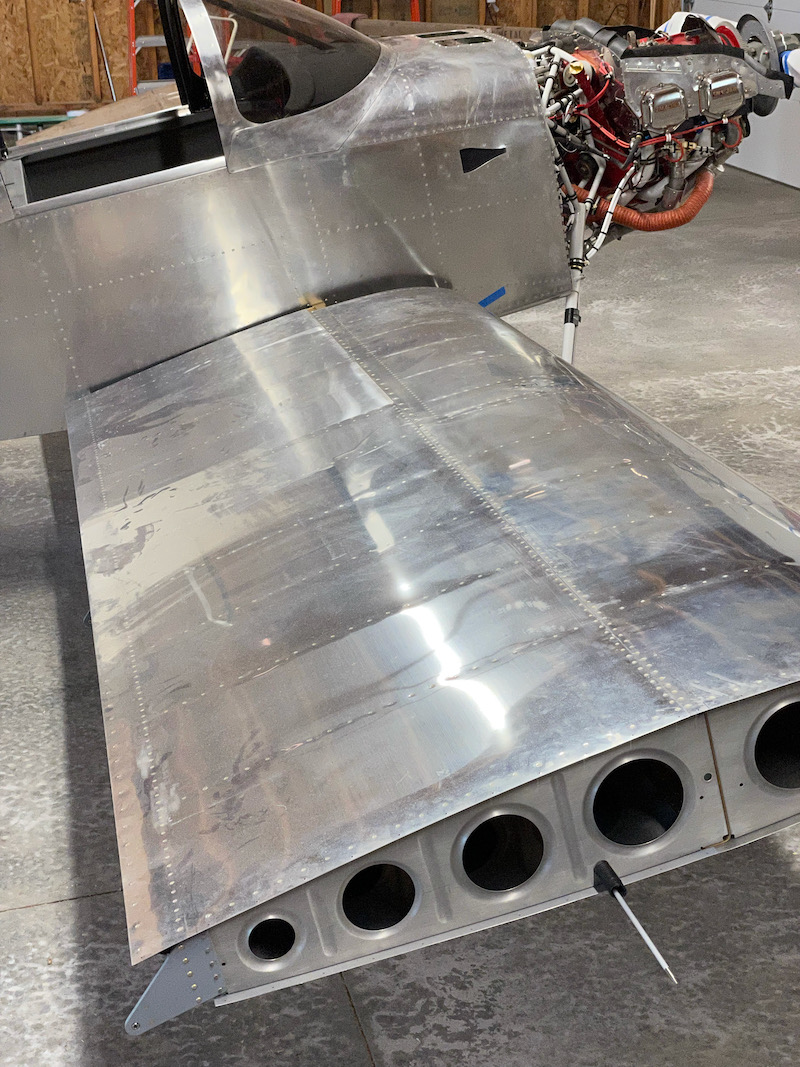

Long ago I followed the factory guidance for installing plastic wiring conduits in my wing ribs. Now that I'm working on attaching the wings, I've realized that the end of the conduit is nowhere close to the prepunched wiring hole in the fuselage (which you can even see in this photo). Since I need to accommodate a pair of 1/4" pneumatic tubes as well as a thick bundle of wires, I was going to need to add more holes in the fuselage anyway, so I decided to use the existing hole for the pitot/AOA plumbing and create a new hole for the wiring.

After checking for edge distance and clearance issues, I decided I ought to be able to put the new hole exactly in line with the end of the conduit. But how to locate the hole accurately? The gap between the wing and fuselage is too narrow to get an angle drill into, and even marking it with a sharpie seemed problematic. Then I thought, what if the hole could be drilled starting from the other end of the wing? All you'd need is a ten-foot drill bit!

I'm sure very long drill extensions exist somewhere, or you could daisy-chain a bunch of the 18" ones together, but those ideas sounded expensive. Instead, I fired up the lathe and made something that did the job, using nothing but stuff I had laying around anyway.

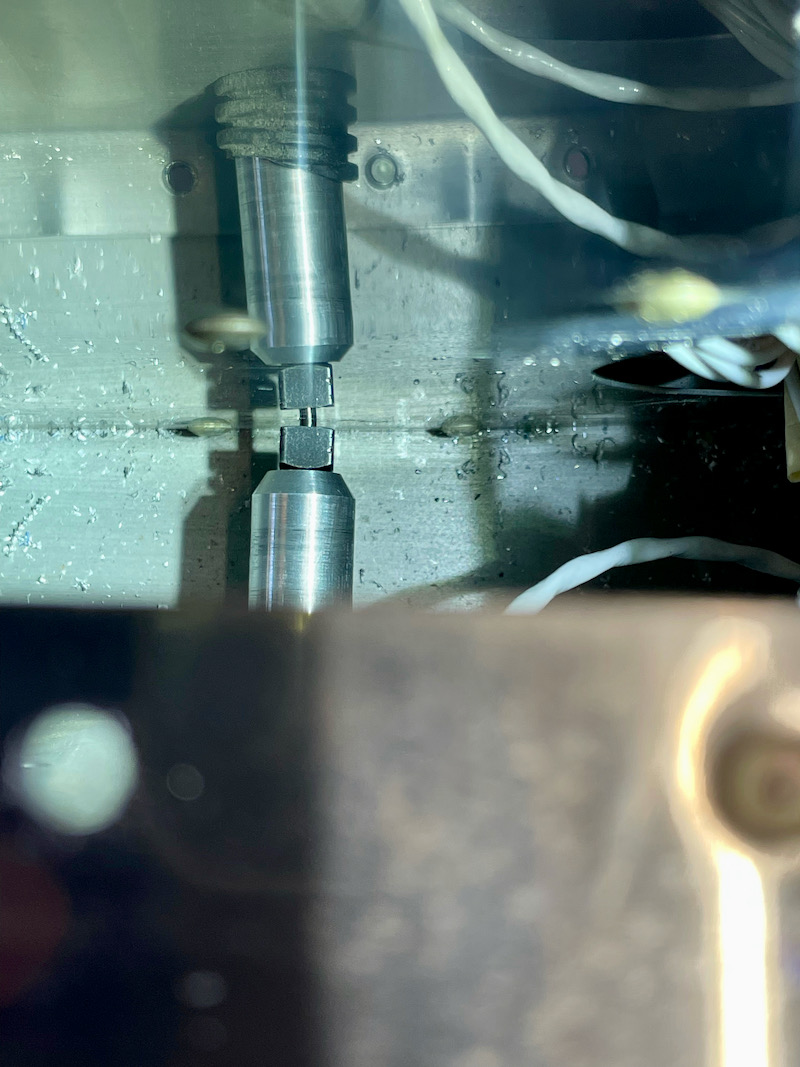

I turned down a piece of aluminum rod into a bullet-shaped thing. One end has an 8-32 stud, and the other end has 1/4-28 threads, into which I screwed a #40 threaded bit:

This I screwed to the end of my electrician's fish stick:

Then it was a simple matter of running the resulting contraption in from the wing tip to the root, chucking the outboard end in a drill, and having at it. It's not totally unlike snaking a drain:

Result, one pilot hole exactly centered on the wing conduit. The space between the fuselage and wing aft of the spar is so tight I could barely take this photo, but you can see (via the reflection) that the "drill snake" has exited the conduit and gone straight into the fuselage skin; only the camera angle makes it look crooked. When the wings come off one more time, I'll enlarge these holes and install plastic snap bushings for the wires.