Finishing up the rollbar brace, I trimmed the excess material off the bottom plate. Luckily this part is 4130 instead of stainless, so it was relatively easy to zip through with a hacksaw and file.

I bolted the brace to the rollbar and fuselage for future canopy fitting. The receptacle on the rollbar is almost too wide for the brace – I may put some thin washers in there to prevent it from being smashed inwards when the bolt is tightened for good.

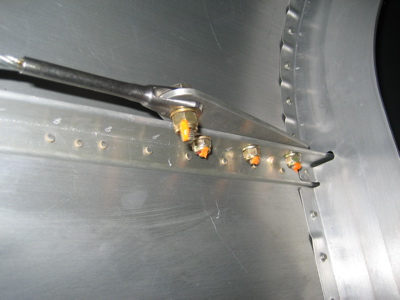

In order to progress further with the canopy, I need to finally get the aft top skin riveted in place. Before I do that, I want to get all the stuff in the tailcone taken care of while I still have decent access. So, I installed the snap bushings and ran the rudder cables:

I also checked the torque on the already-installed seatbelt anchor brackets, and bolted the seatbelt cables in place:

Then I got out the aft top skin and discovered that I never finished deburring and dimpling it – probably because I anticipated that it would be really boring. So I did, and it was.

I hadn't yet riveted the F-787 stiffener in place, so I did it tonight. With the slider canopy you're supposed to use three rivets on the front flange, and leave the bottom hole open. The plans also say to leave open the hole that's in the upper right corner of this photo, although they don't say why. Curiously, the quickbuilders put rivets in three of the four holes where the F-728A bellcrank channel meets the F-706 bulkhead, but they left the top hole open. Since it was already dimpled and I couldn't find a note in the plans about it, I put a rivet there too.

At the aft end of F-787, I was able to squeeze the lower rivet but I had to shoot and buck the top one. This photo makes it look trashed but it really isn't, it's just marked up a little bit. I infinitely prefer squeezing rivets wherever possible, though.

Next step is to paint the visible parts of the inside face of the aft top skin, then rivet it to the fuselage.