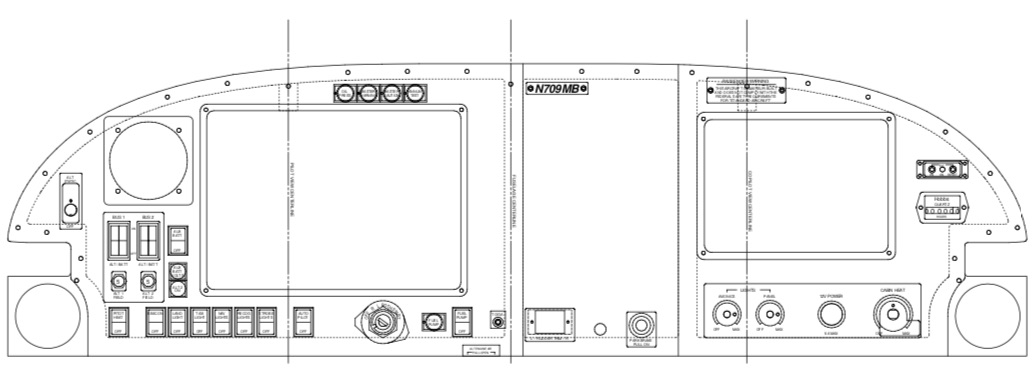

Before I moved across the country and put my project on hiatus, I had been working on a partial panel redesign to incorporate G3X Touch displays. I left the radio stack alone, but I had Steinair cut me two new pieces for the left and right halves of the panel so I could change the displays around. The main change was to replace my previous GDU 37x (7" portrait) displays with a GDU 465 and a GDU 450 (10.6" and 7" landscape screens). Electrically everything was nearly plug-and-play, with just a few wires needing to be moved around to accommodate the change from three displays to two. I also took the opportunity to replace the steam gauge backup instruments with a G5 electronic instrument, which is what the round hole on the pilot's side is for.

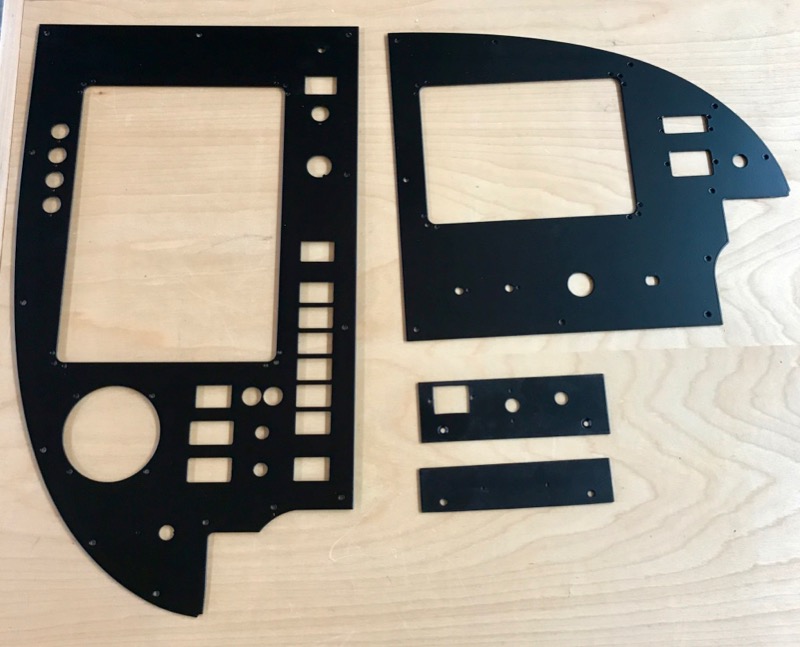

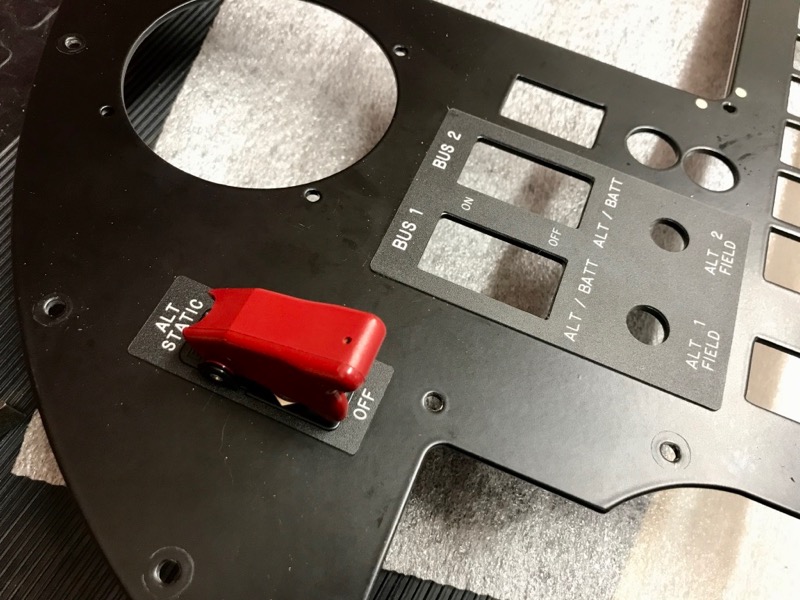

That's the last thing I was working on back in 2015, and more recently I found that I'd left myself plenty of loose ends to tie up, both literally and figuratively. When I finally reached a point where I couldn't proceed any further without having the panel installed for good, I took the pieces to a local powder coat shop to have them finished. It took a while, but I eventually got everything back and looking sharp in matte black:

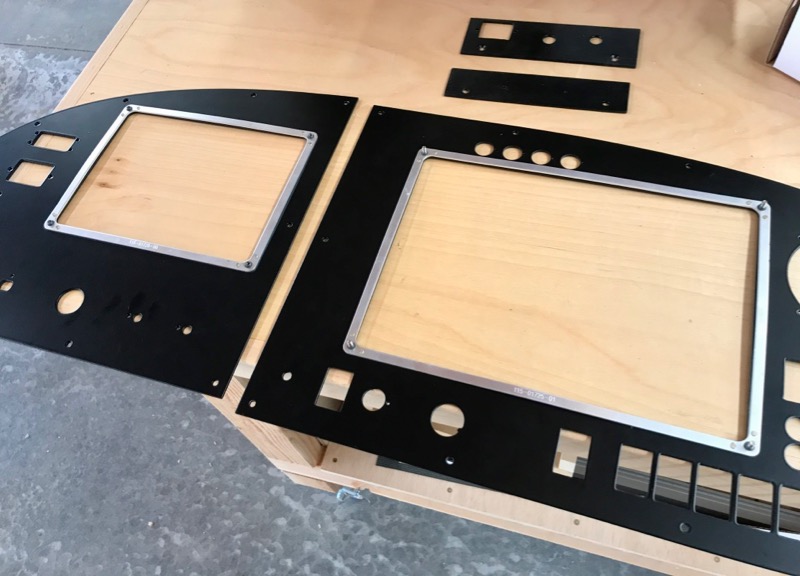

On the reverse side of the panel, I riveted the nutplate rings for the Garmin displays:

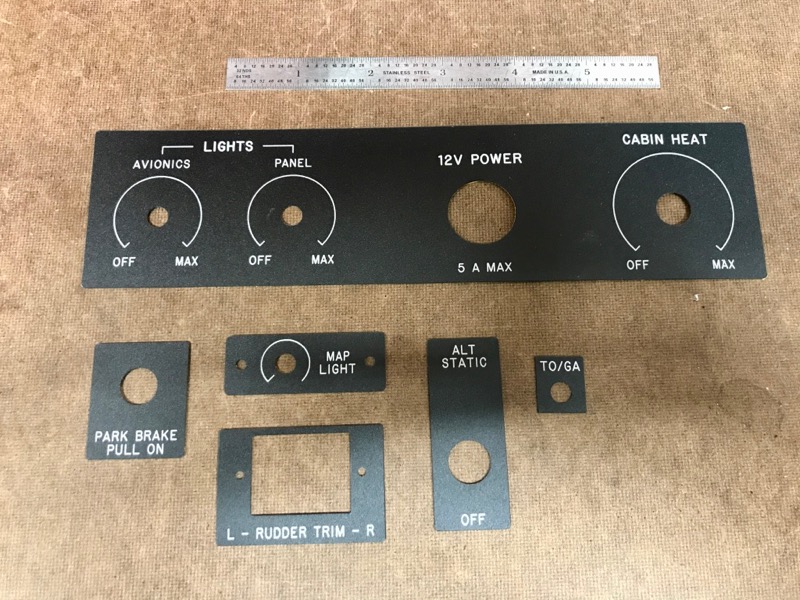

I had Aircraft Engravers make me a set of panel placards in 0.020" Lexan, a few of which are shown here prior to installation. These are engraved and paint-filled on the reverse side, so the markings are protected on the front side and can't be scratched. Should hopefully be tough as nails.

The placards have an adhesive backing – here I'm carefully aligning the biggest placard before sticking it down:

Detail view of the placards on the left side of the panel:

All the controls at the bottom of the radio stack have their own labels:

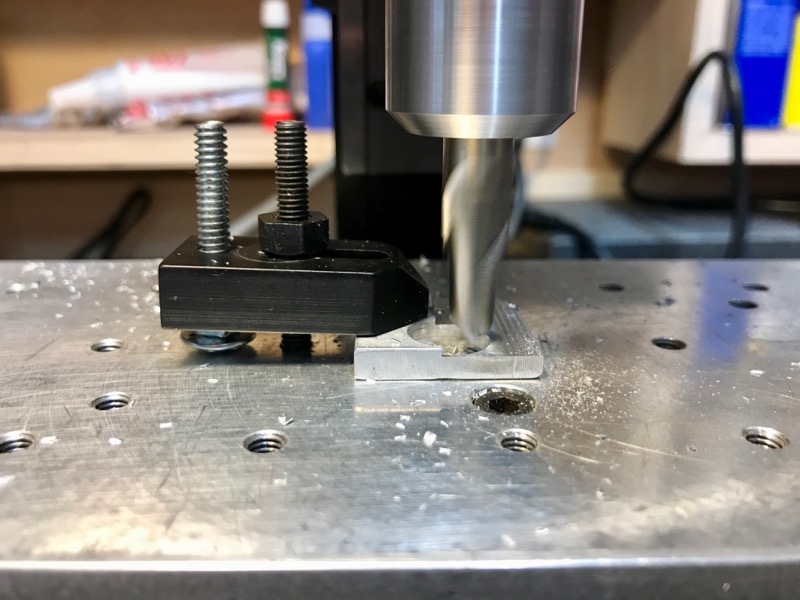

For the final installation, the flap switch spacer needed a bit of thickness adjustment – no problem to shave off a few hundredths on the mill:

Here's the new panel after being physically screwed in place. As part of this sequence I also had to attach the air vents to the panel, since a few of the vent mounting screws are obscured by the panel plates.

This is the mounting bracket for the G5 instrument. It just barely clears the panel substructure. I'd like to say I planned it this way, but truthfully I just got lucky.

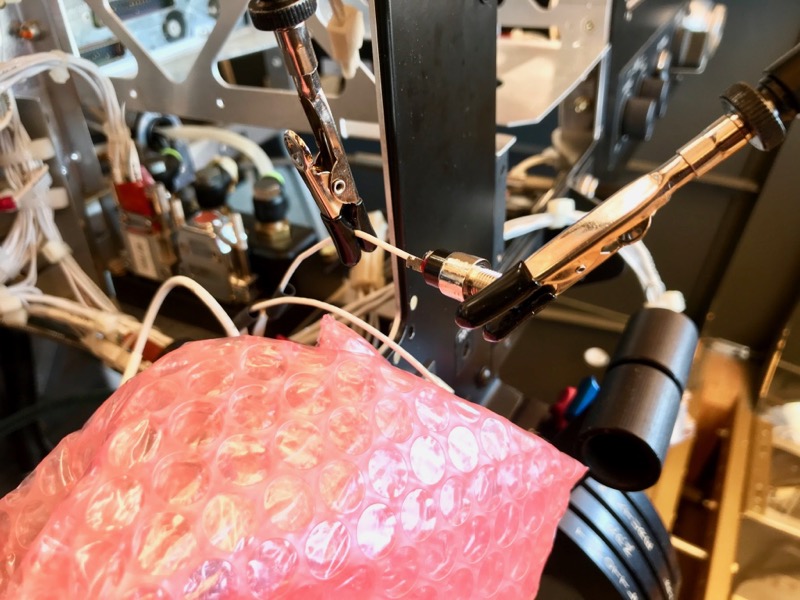

At this point I had a few items in the panel that needed to be installed with soldered connections, including the TO/GA button shown here. I used a pair of magnetic helping hands stuck to a clamp to keep things from moving around while I did the soldering.

I rethought my previous idea of having a start button on the stick grip – now I have a more traditional ignition/start key in the panel. Here you can also see the placard labels for the TO/GA button and the alternate engine air cable.

This is the knob for the rotary heat vent control. The knob fits tight to the input shaft, but there's some play in the gear mechanism, which allows the knob to wobble. To fix this, I made a simple friction washer out of thick felt, to fit between the knob and the panel:

All the knobs and most of the small devices on the right side of the panel are installed here. With the felt washer in place, the heat knob moves smoothly but shouldn't be able to wobble from vibration.

The 3.5mm auxiliary audio jack is soldered in place, with plastic shoulder washers to electrically isolate it from the panel. Here you can also see how I used black oxide coated button head screws and washers to attach the panel and the devices in it:

On each side of the cockpit I installed the labels for the map light dimmer knobs, although I'll leave the potentiometers themselves hanging loose until after I set the rivets that live just behind here:

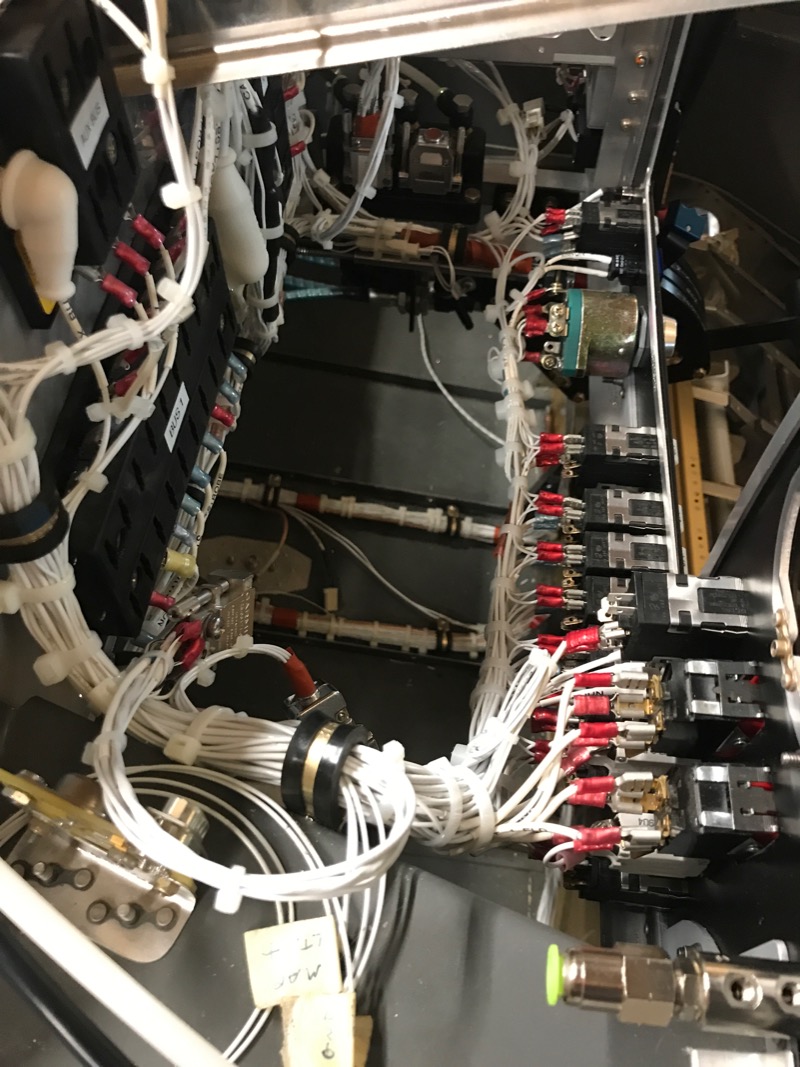

After lots of work tidying up and securing things, here's what the behind-panel wiring looks like. There are still a few loose wires outstanding, waiting for the top skin to be installed, but I think it looks pretty good for now:

Here's all the non-removeable panel components installed, and the electrical wiring complete and ready for careful testing:

The pilot's display and G5 are shown installed here. There are six annunciator lamps and a test switch in the panel, all of which are waiting for a set of labeled lenses that I've ordered from Aircraft Engravers. So for now they are just pretty colored lights with no text on them.

And after some methodical circuit-by-circuit testing, here it is all lit up. Somehow in the past five years I managed to develop one short circuit (in the pilot's right headphone audio channel) but I managed to repair the offending wire and now everything appears to be working as designed.

Here's the panel in darker lighting conditions, showing the backlit rocker switches. Even at minimum brightness the LED lamps in these switches are pretty bright – I'll deal with that later if need be.

One consequence of taking five years off from building is that parts of my panel have become positively antiquated. The GNS 430Ws especially are getting pretty long in the tooth, being now two generations out of date, although these particular units are practically brand-new. I did give serious consideration to tearing them out and rewriting the ratio stack for a more modern navigator, but in the end decided that I should stop redoing previous work and just focus on driving towards the finish line.