Today's task was to flush the fuel tanks, test as much of the fuel system as possible, and calibrate the fuel quantity gauges.

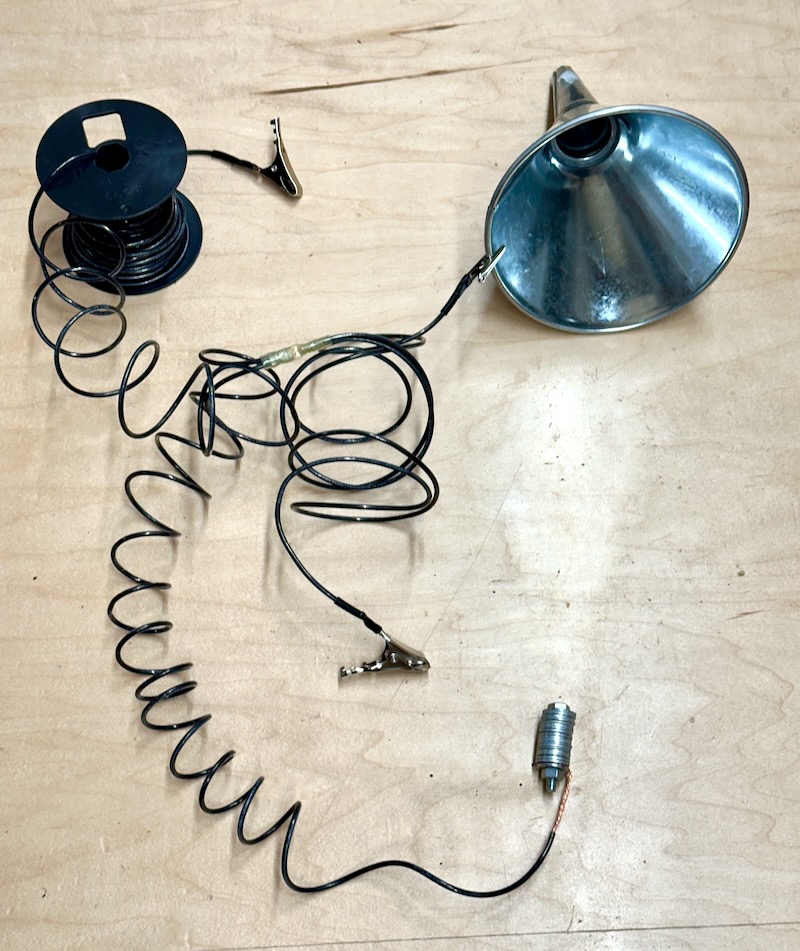

To avoid blowing myself up, I fabricated this simple grounding harness from a spool of hardware-store wire. It has one alligator clip for the airplane, one clip to attach to a metal funnel, and a third clip on the end of a long run of wire that I can connect to a ground rod if needed. There's also a length of wire with a weight on the end (made from a bolt and a stack of washers) which I can drop down the neck of a plastic gas can. The goal here is to prevent a potential difference between the airplane and the fuel container due to the static electricity generated by fuel flowing from a tank being drained, which could otherwise cause a spark. This might be overkill, but fuel flowing through rubber and plastic can do funny things, and I enjoy not being exploded.

I temporarily removed the fuel tank drains, and installed a pair of ball valves with rubber fuel hose attached. With this setup and the ground rig connected, I flushed about ten gallons of avgas through each tank, draining it back into the gas cans through a clean paint filter:

Happily, I only found a few tiny particles of trash in the filters, and nothing leaked:

Then I disconnected the fuel hose at the inlet to the mechanical fuel pump, and used the electric boost pump to run several gallons from each tank through the fuselage plumbing and back into gas cans. This allowed me to check most of the plumbing for leaks, verify the operation of the fuel selector, and test the boost pump and fuel flow gauge. I put a lawn-mower fuel filter in the temporary drain hose to avoid putting any trash back in circulation:

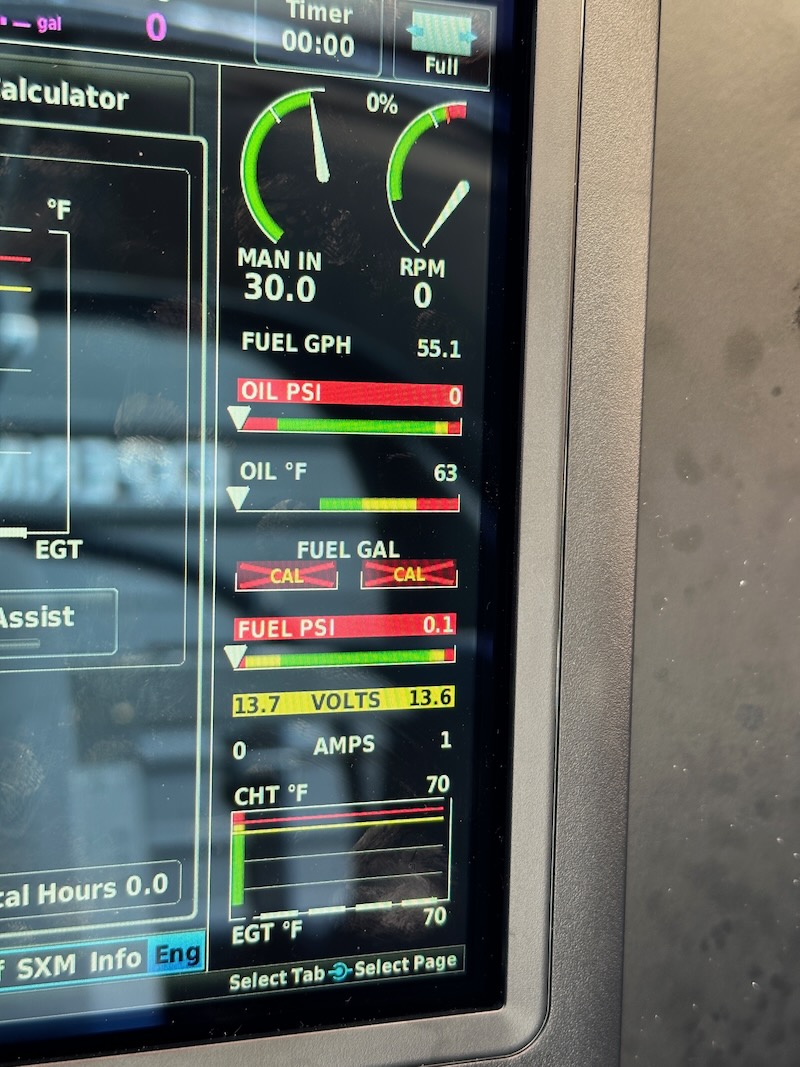

The fuel flow gauge was showing about 55 gallons per hour with the boost pump drawing from either tank. Judging by my watch, it was filling the gas can at the rate of about a gallon every minute, so that number seems believable. No fuel pressure indication here, since the hose is disconnected:

I recruited Mary to push buttons, got her situated in the seat, and then heaved the tail up onto a stand to level the fuselage:

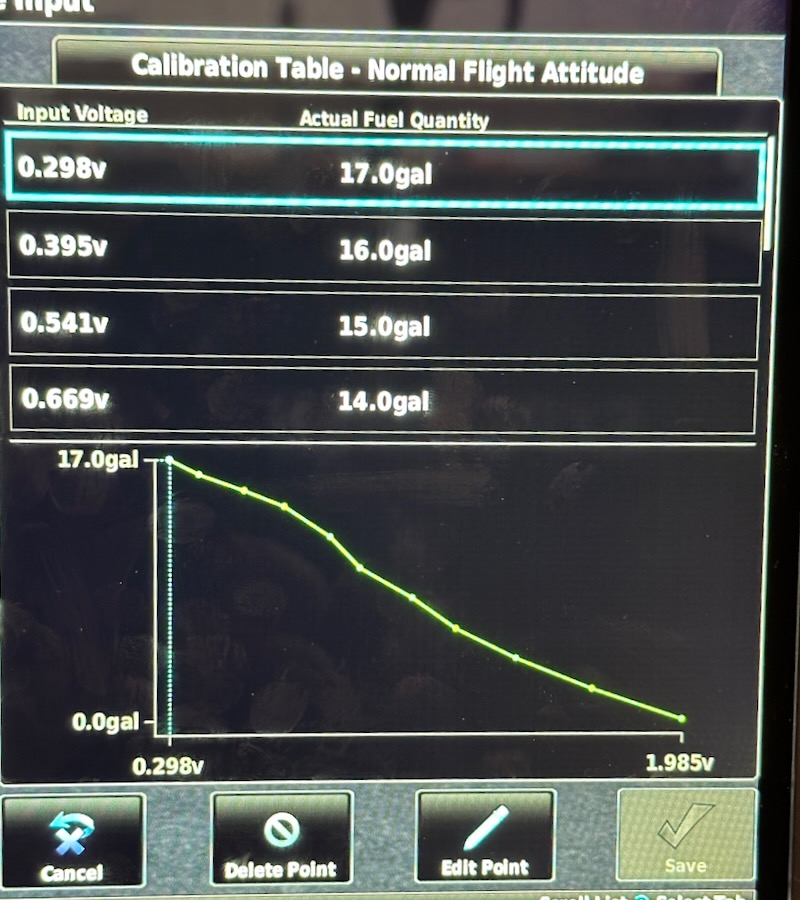

Using a calibrated fuel container, I added two gallons at a time and had Mary record each calibration point until the gauge stopped registering. For the right tank, we had no problems with the calibration process and were able to record points up to 17 gallons. Above that level, the float tops out due to the dihedral of the wing:

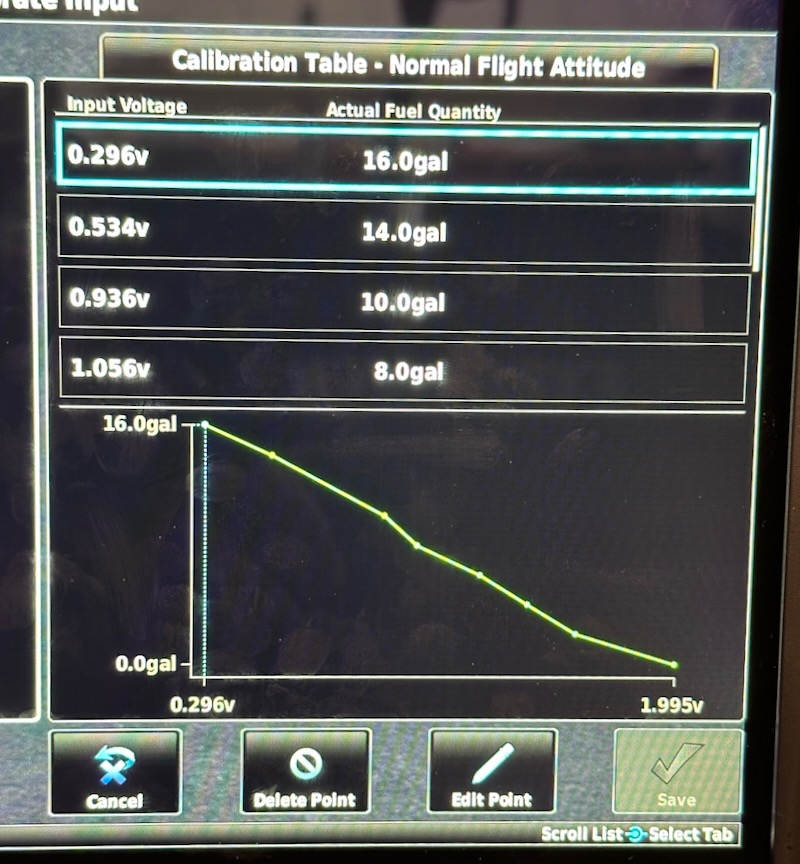

The left tank seemed to have a sticky float, requiring a lot of tapping to get it to register changes in fuel level. We were eventually able to get a believable calibration curve out of it, but I'm not completely convinced. I'll monitor this and see if it frees up with use, and hopefully I won't have to pull the sender to fix it:

After filling and calibrating each tank, we then used the boost pump to drain the fuel back into gas cans again.

Mary the long-suffering assistant rated the Classic Aero Aviator seats as "like the seats in an upscale SUV":