The in-laws were in town so I didn't do any work on Friday or Saturday, but today I was able to spend the afternoon out in the garage, building airplanes and enjoying the nice weather. I rolled the leading edge of the right elevator as best I could, and since I figured I'd have a similar puckering problem on this elevator I went ahead and doubled up on the rivets for the middle and outboard sections while I still had it clecoed together:

That made it turn out pretty nice. I think the problem with the elevators is that the skin is too stiff and the spar is too narrow at the tip to get a nice bend out there; I probably also could have used a smaller-diameter broomstick and gotten better results. It turned out acceptably though:

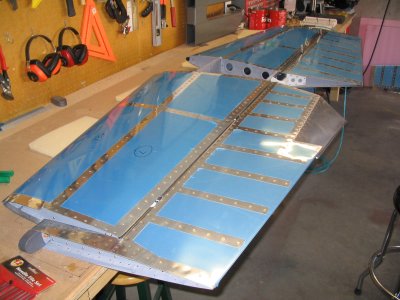

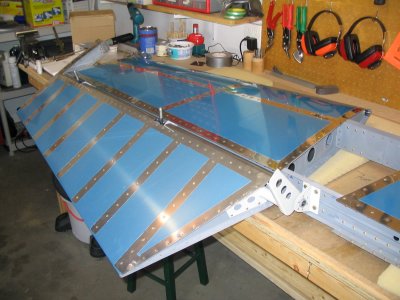

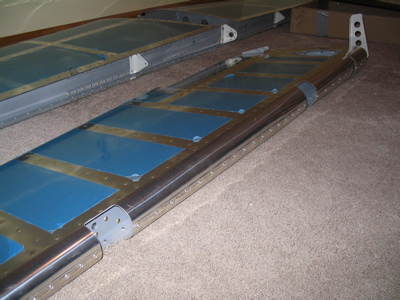

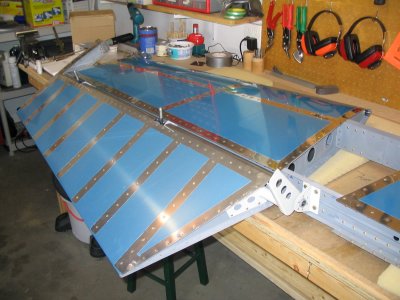

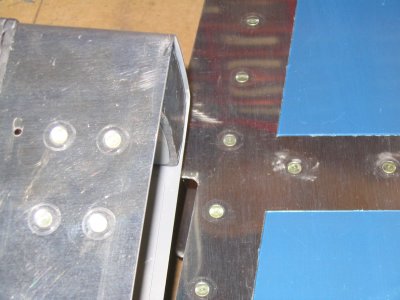

Then I hauled the horizontal stabilizer out of storage, and went to work getting the elevator hinges set up:

I used Avery's temporary alignment pins to hold the elevators in place while I worked – way easier than putting bolts in and out. I must have had the elevators on and off a half dozen times today, and these pins made the job a lot simpler. I also used Avery's rod end bearing installation tool to (surprise) install the rod end bearings, although if I'd been feeling industrious I could have made my own out of PVC. I don't actually remember ordering the Avery one, but I found it in my toolbox so I must have been planning ahead during some previous tool-buying spree. Or maybe it was the tool fairy…?

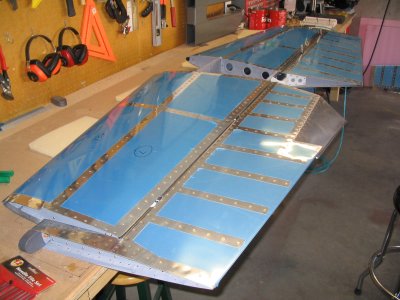

Behold the newest addition to our country's military arsenal – the F/A-RV-7 Stealth Attack Geo!

Here is another shot, this time with the wings folded for supersonic cruising flight!

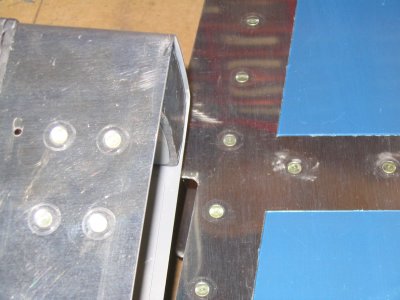

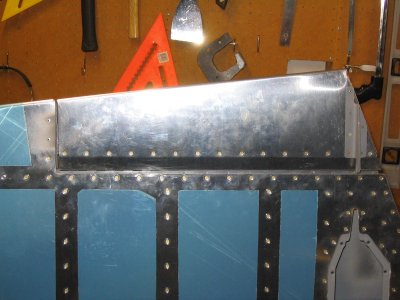

The elevator counterbalance arms were way too long to fit the cutout in the stabilizer skin – I think Van's must have changed the elevator design at some point without changing the HS to match, because I've read about this problem happening to a lot of builders.

I trimmed about 3/4" and now everything fits together. This will be cleaned up and deburred after I take the elevators off again.

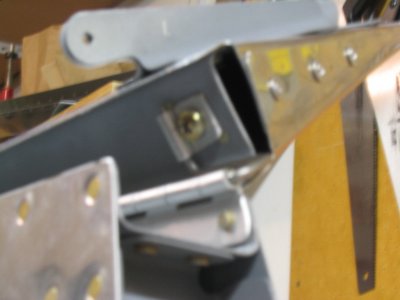

I also had to notch the lower flange of the HS spar, per the plans, to clear the elevator horns and allow enough down-elevator travel.

Here's the HS with both elevators temporarily attached. This thing is huge – over eight feet wide. Sweet.