I iteratively cut about an eighth of an inch at a time off the bottom end of each canopy frame tube until they were the same length and the frame was aligned height-wise with the rollbar.

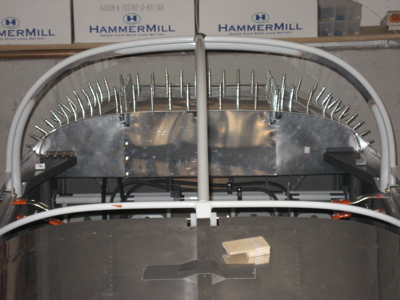

Viewed from the tail, the frame looks straight and the contour matches the rollbar. The canopy frame is supposed to sit higher due to the downward curvature of the canopy in that area.

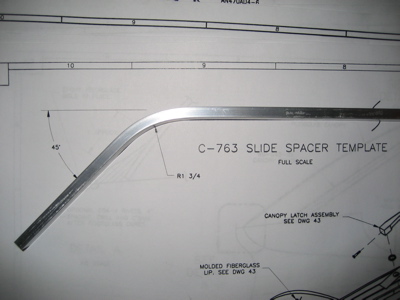

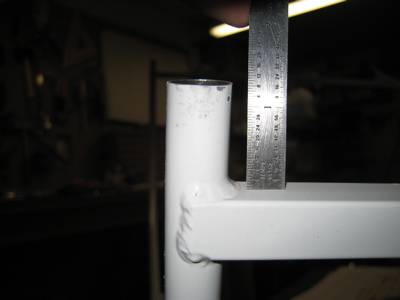

My little offset-measuring tool shows the proper 1/16" spacing between the fuselage sides and both sides of the canopy frame at the front end:

…and the back end:

In this photo the rear bow of the frame is exactly 1/16" below the curvature of the aft top skin, but in the end I made the frame sit slightly above this level based on various pieces of advice I collected from various discussion archives. The rear canopy skirt will cover any mismatch and I think the fit will be easier with a little extra height back there.

Update: The above advice was not that great. I had to make my aft skirts out of fiberglass to cover the height difference. The plans really are correct here.

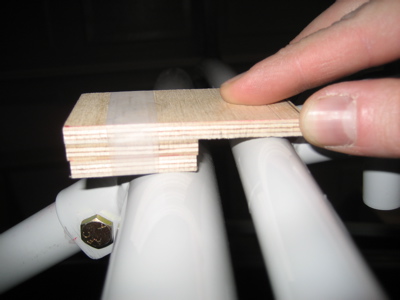

After trimming the canopy frame tubes, the front bow of the canopy sits the required 3/8" above the rollbar. I made this little measuring tool from more scrap plywood. Handy stuff.

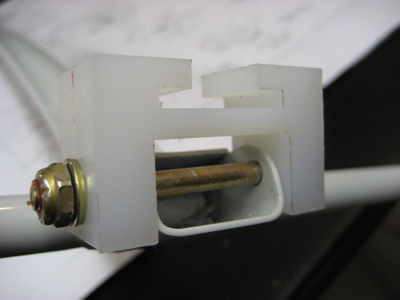

I must have had the canopy on and off the airplane thirty times, trimming the tubes and making small adjustments to the shape by bending it in various ways. Once I was happy with the fit, I drilled the canopy tracks to the fuselage. The rearmost screw hole ends up very close to the longeron, so I had to be careful not to nick it. (that would be bad)

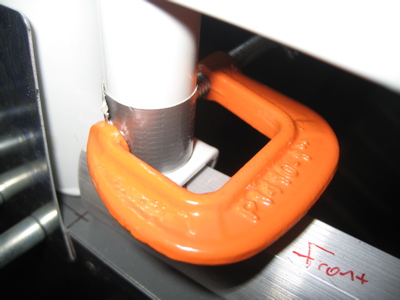

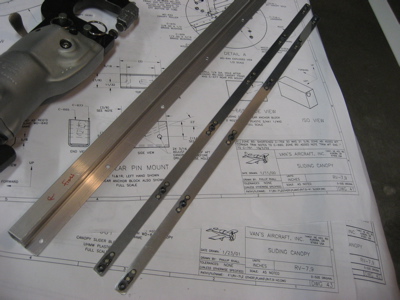

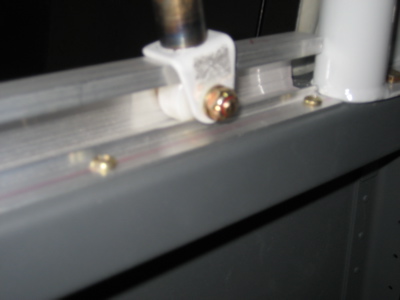

The plans call for you to use regular nuts and washers up under the canopy deck to attach the tracks to the fuselage. I decided that was an excellent recipe for frustration, since you can't see what you're doing up under there. So instead I made these nutplate strips out of some scrap material. I didn't invent this idea but I'm glad I used it because it was a snap to get the track screws in.

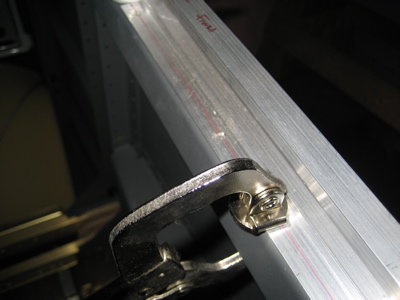

Fuzzy picture of the canopy tracks attached to the fuselage. The plans actually leave you hanging after they say "drill #40 the tracks to the fuselage" and never tell you when you should drill up to the final size and put the screws in. I reasoned that it makes sense to do it now, or else the clecoes would prevent the canopy from opening and closing while you're working on it.

Update: It's easier if you leave all but the two end holes at #40, so you can tweak the position of the tracks later on if you have to.

I likewise drilled and countersunk the slide rail for #6 screws and installed it temporarily on the fuselage.

Update: Again, only attach the rail at the forward-most and aft-most ends at this point. Later on, when the canopy is almost finished, you can drill the remaining holes. If you do it this way it will be easier to build a canopy that slides easily.

Behold, the canopy in its closed position:

…and slid to the open position:

I have a little interference between the skin and the rear canopy bow on the right side. I need to tweak the bend there and then I think I'll be done fitting the canopy frame.