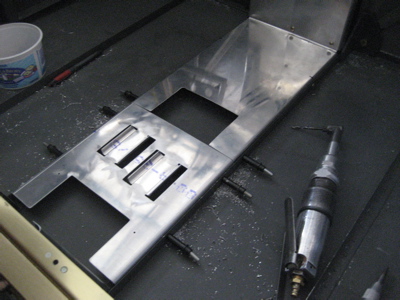

I still need a few more electrical components before I can start mounting things on the firewall, so I decided to work on the electric fuel pump installation. The high pressure electric fuel pump sits on the floor just in front of the fuel selector, so the first thing you do is lop off a chunk of the center cabin cover and then cut a notch in it:

You also have to take a big bite out of the fuel selector housing:

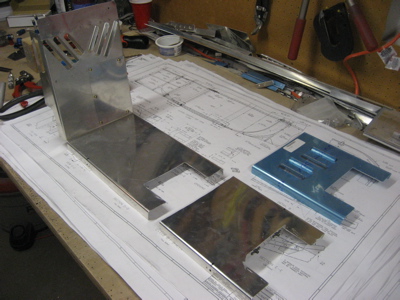

The fuel pump bracket is attached to the center cabin floor stiffeners with screws and nutplates. Here I've drilled the mounting holes. Note the orientation of the pump bracket – it looks like it's supposed go the other way around, but this way is actually correct. I actually had it in backwards at first so now I have a few extra lightening holes in my bracket. No big deal.

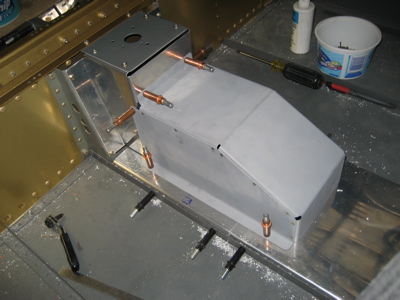

Next I built the lightweight aluminum housing that covers the fuel pump and associated plumbing. I primed it before riveting since it will get a coat of paint later.

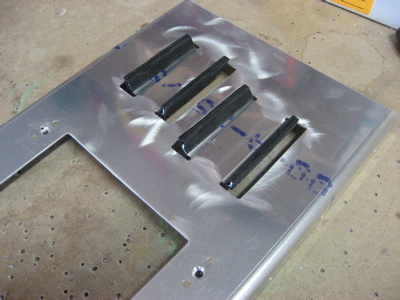

Then I drilled the mounting holes that attach the pump housing to the other items (with more screws and nutplates).

The upward-pointing flanges on the pump bracket get some rubber material put on them to protect the pump and filter:

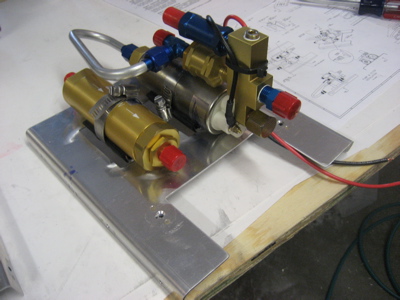

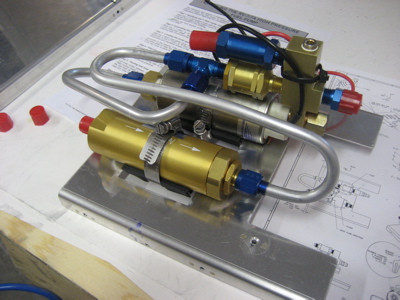

The fuel pump and manifold and the fuel filter are secured to the bracket with hose clamps. The piece of aluminum tubing shown in this photo is already installed when you receive the pump, but there are more lines you have to fabricate and install yourself. Here's a diagram I found that helps a little to explain what all the various components are there for.

I had no real problems fabricating the first line, from the output of the filter (large gold cylinder) to the tee on the input to the check valve (small gold cylinder). The remaining lines all connect to other parts of the airplane, so I'll have to fabricate those with the pump/filter installed in the fuselage.

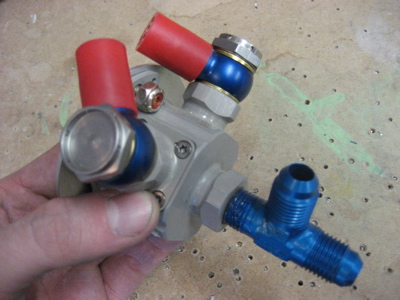

You need to install a tee at the output of the fuel selector, for fuel feed and pressure return. In order to get the fitting clocked in the right direction, I had to use copious amounts of fuel lube on the threads and whack on it with a big wrench. I almost thought I was going to twist it off, but I got it pointed the right way. I don't think it's ever coming out again, though.

While I had the fuel selector housing out, I riveted this little angle onto the top plate in order to cover up the gap that most RV's have there (see example in photo above). You probably won't ever be able to actually see this from inside the airplane, but whatever.

I wanted to see how my Classic Aero carpet fit around the fuel pump housing – answer, perfectly. When you order the carpet they ask you if you have fuel injection or not, and they obviously know exactly how big to make the cutout to go around the pump housing.

Next I need to decide where to mount the fuel flow sensor, which will be a bit of a pain.