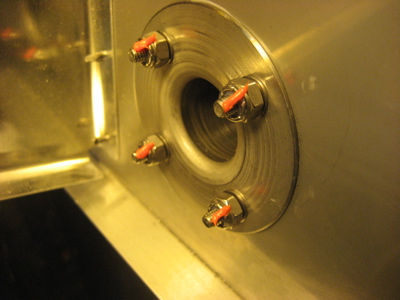

I used my Greenlee punch to put a 1 1/8" hole in the upper starboard corner of the firewall:

…through which I then installed a firewall passthrough fitting from SafeAir. Read this article from Bob Nuckolls for the background on why you'd want to bring wires through the firewall in this way. I also squirted some Biotherm firestop sealant between the fitting and the firewall, the better to keep fumes out.

The fitting has a nice radius on the aft side, so it won't chafe my wires. I'm planning to bring all the heavy electrical wires through here, and possibly the Lightspeed ignition wires as well if the routing works out. The small-signal stuff will all go through a separate passthrough, to prevent inductively coupling noise from the power/ignition wires into the sensor leads.

There's a different and somewhat similar stainless firewall penetration kit sold by EPM-AV (whose site is unreachable at the time of this writing) which I actually bought before I decided to use the SafeAir kit instead. Here you can see that the EPM fitting is made of rolled and welded stainless sheet, instead of being a one-piece spun part like SafeAir has.

Call me crazy, but I just don't like the idea of having sharp edges near my wires. Add to this the fact that the SafeAir kit is more complete, uses a hole size that I already have a punch for, and is slightly cheaper, and I know which one is my favorite.