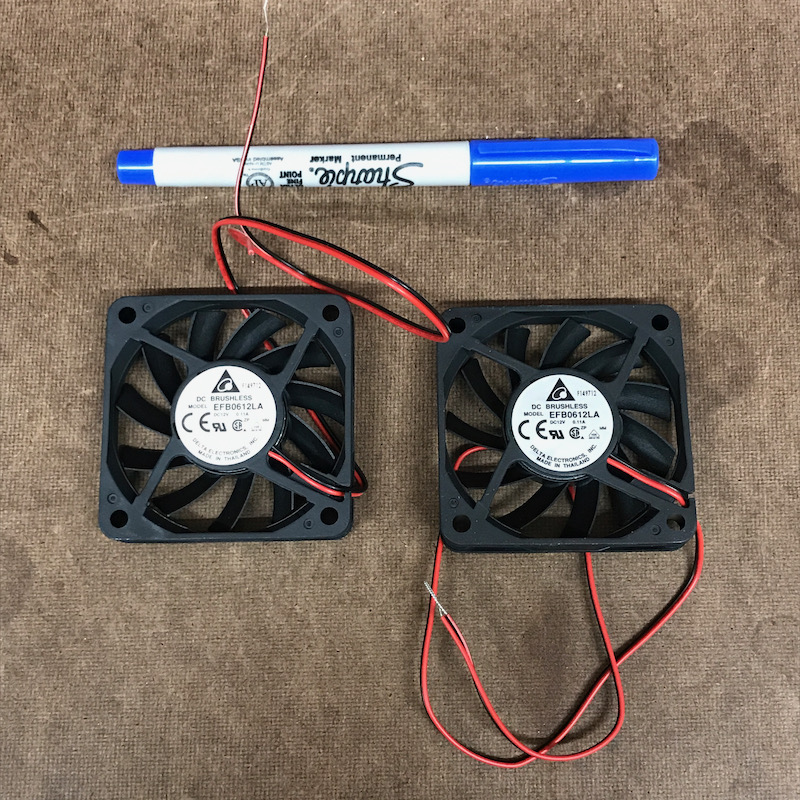

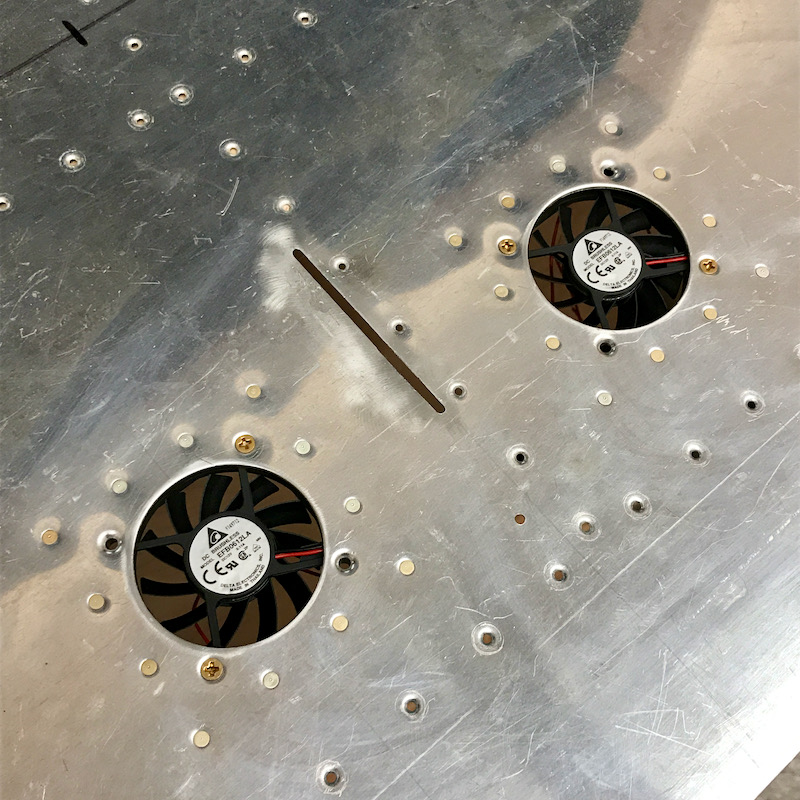

I bought a pair of low-power 60 mm computer fans, which I plan to use for moving warm air from under the panel and blowing it on the base of the windshield:

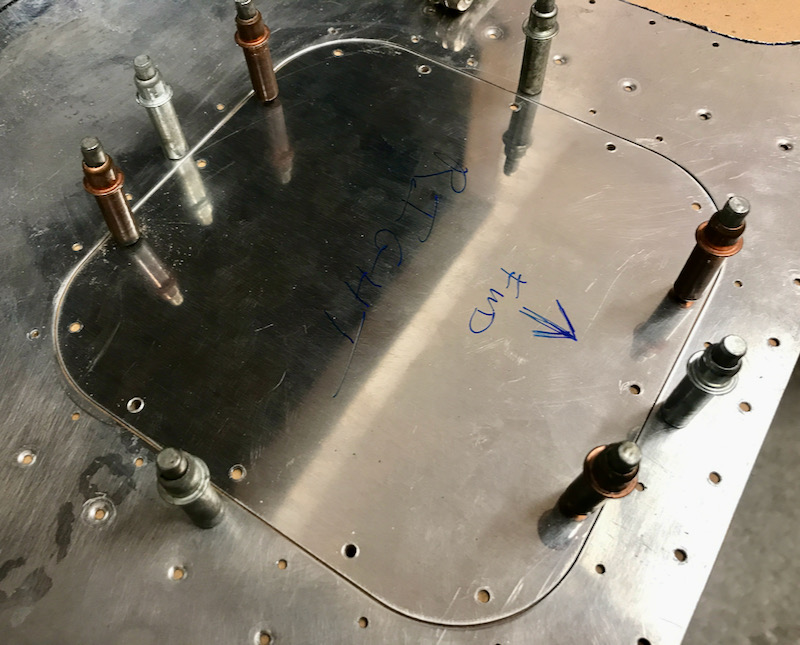

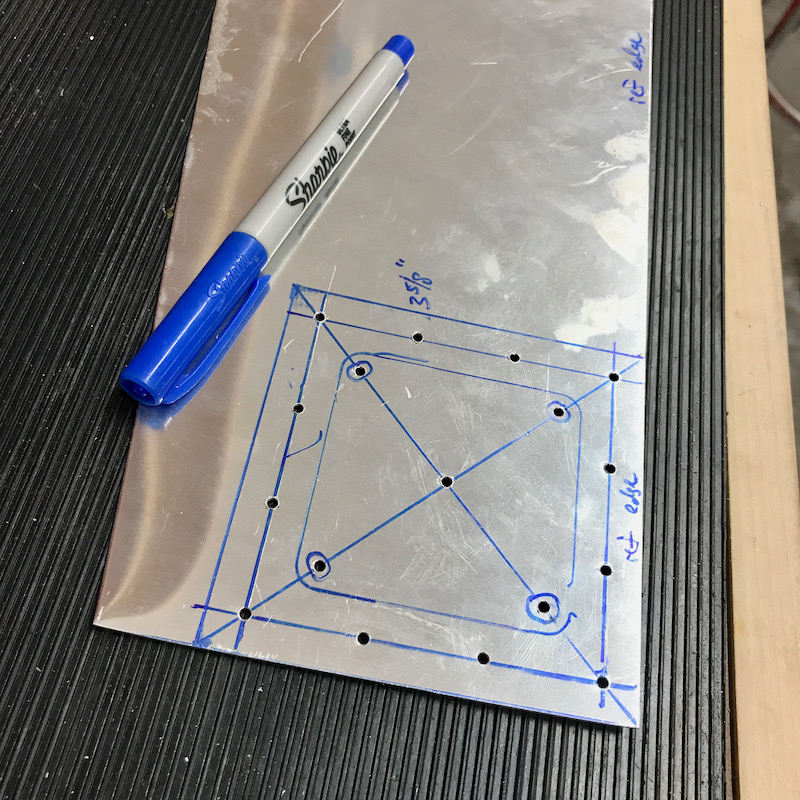

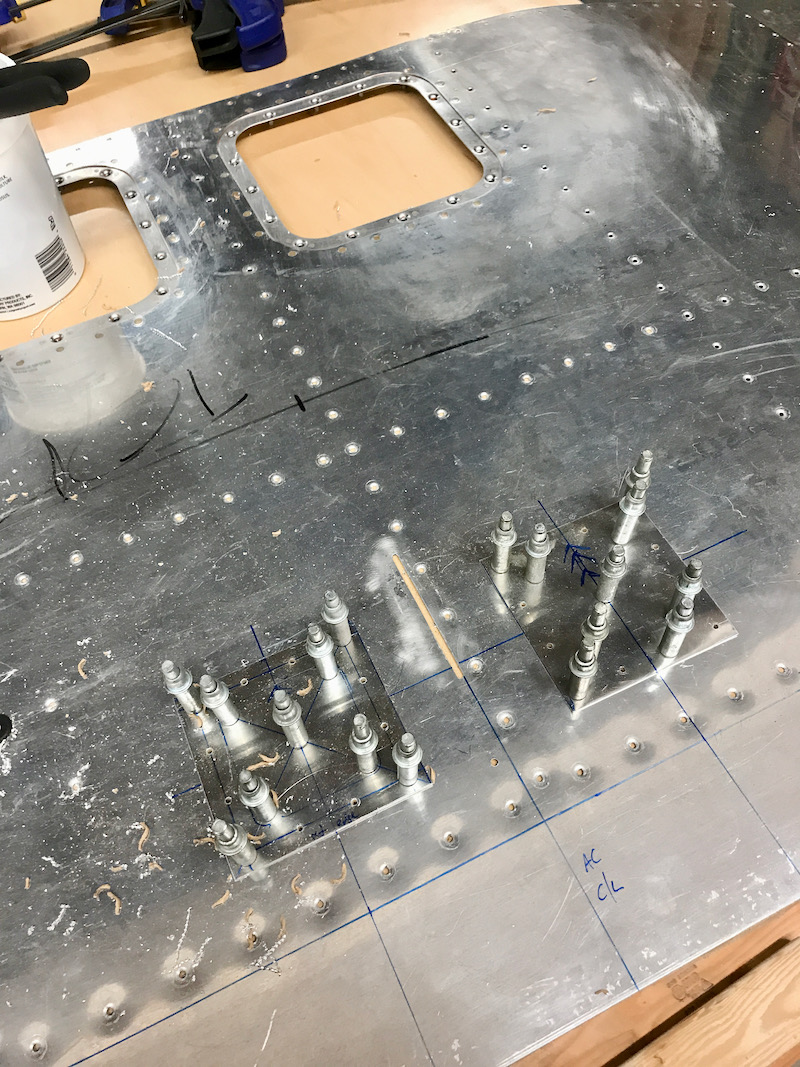

I laid out a simple doubler on a scrap of 0.032" aluminum, then made a second one by match-drilling with the first:

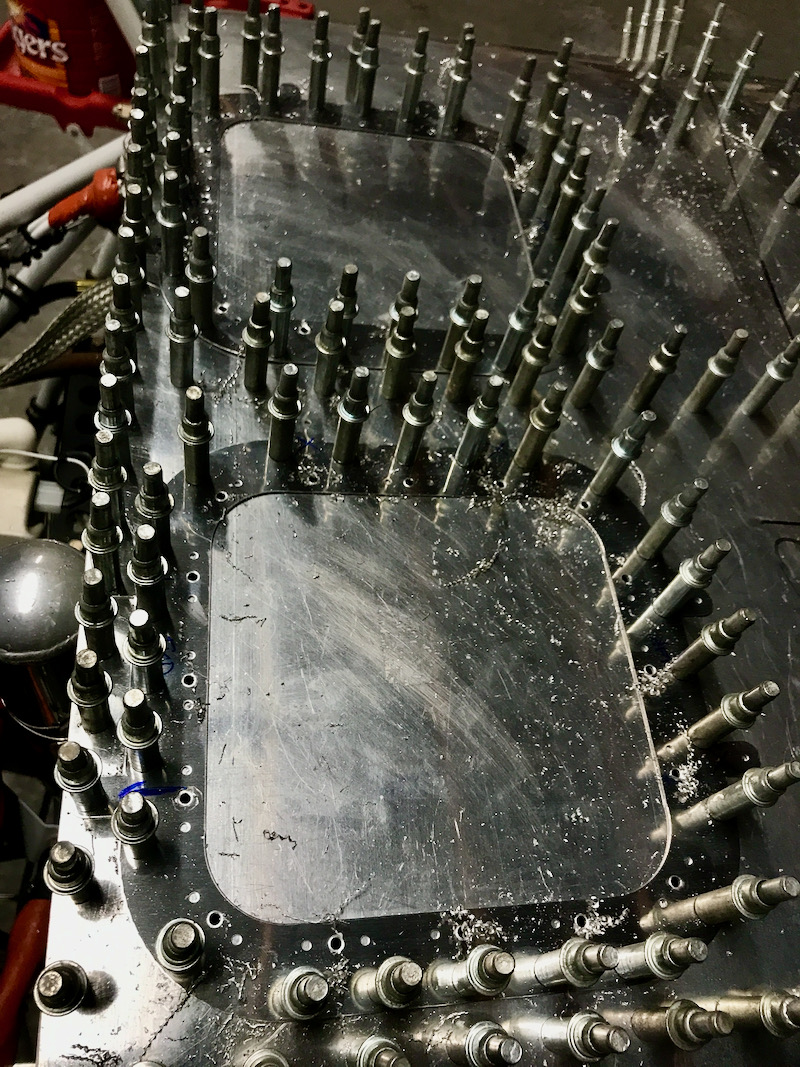

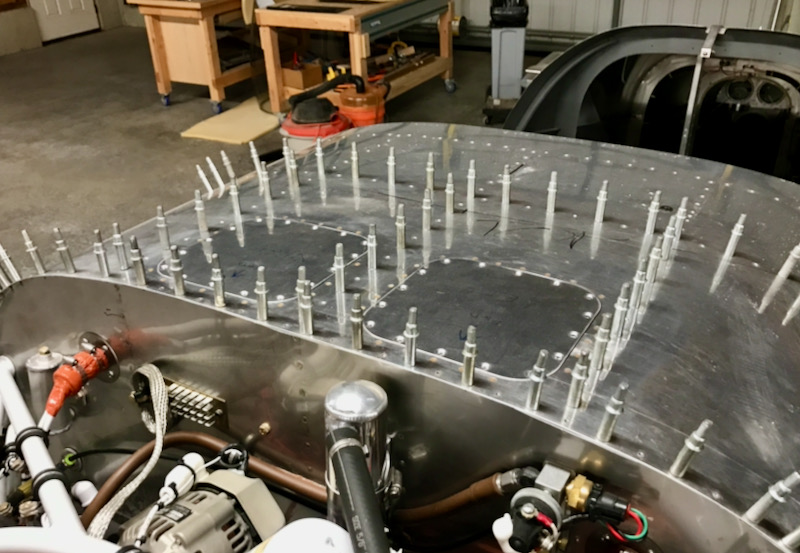

I figured out where I wanted to mount the fans, then drilled the doublers to the skin in the correct location:

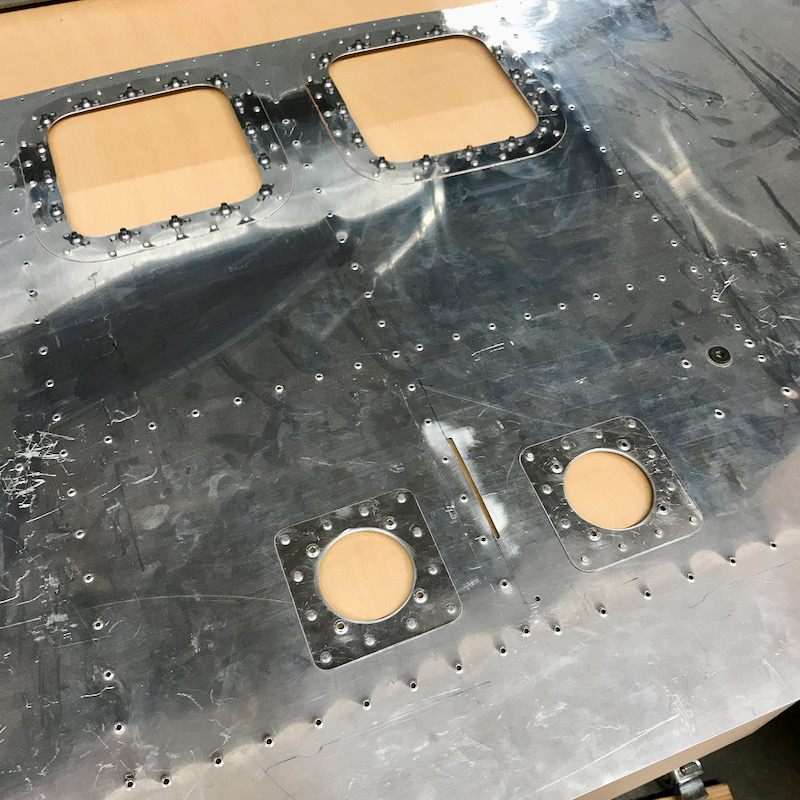

I enlarged the center holes up to 5/8" with the doublers clecoed in place:

The 5/8" hole allowed me to use my instrument hole punch to make 2.25" holes for the fans – coincidentally that's very close to 60 mm. I love this tool, it's massive and does its one job perfectly (and was made in the US!).

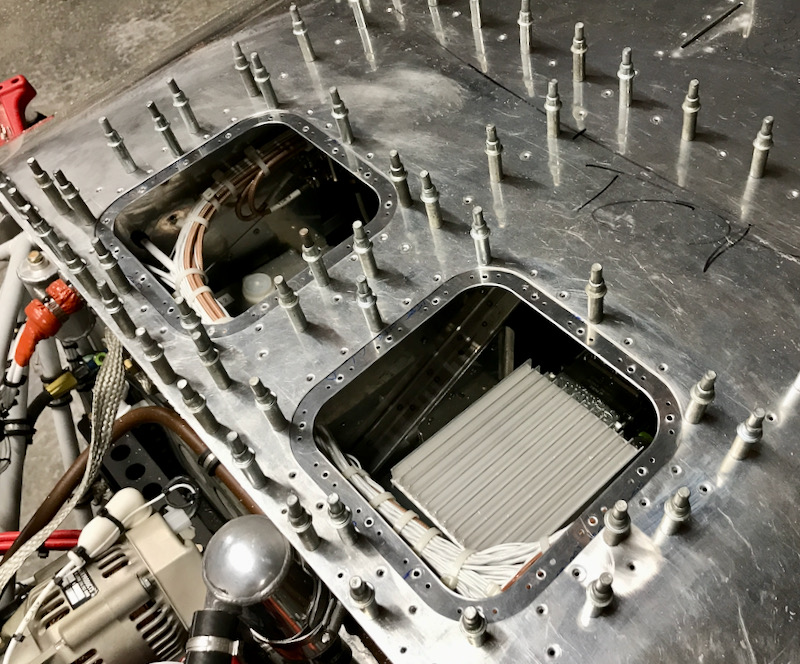

Deburred, dimpled, and back-riveted the doublers to the inside of the skin:

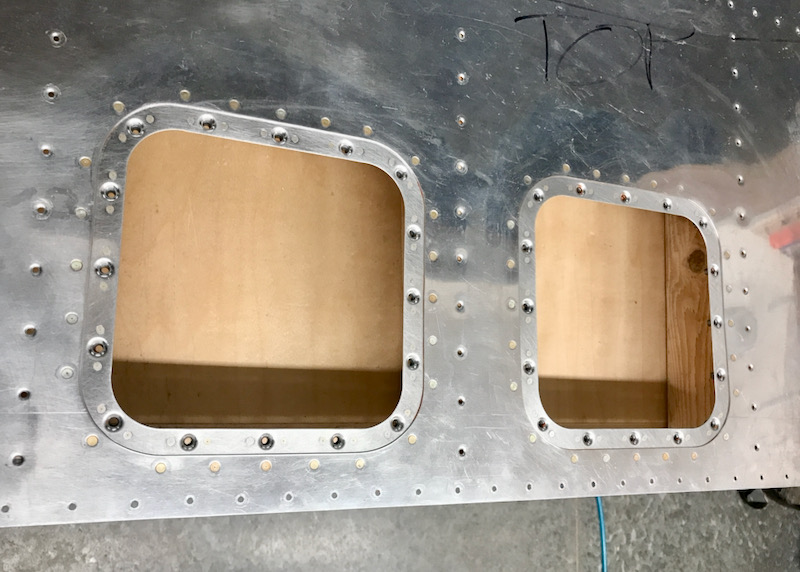

This is what the fans look like when affixed with some temporary hardware. I need to get the correct screws to use here, and also make or purchase some kind of cosmetic cover to dress them up a bit.

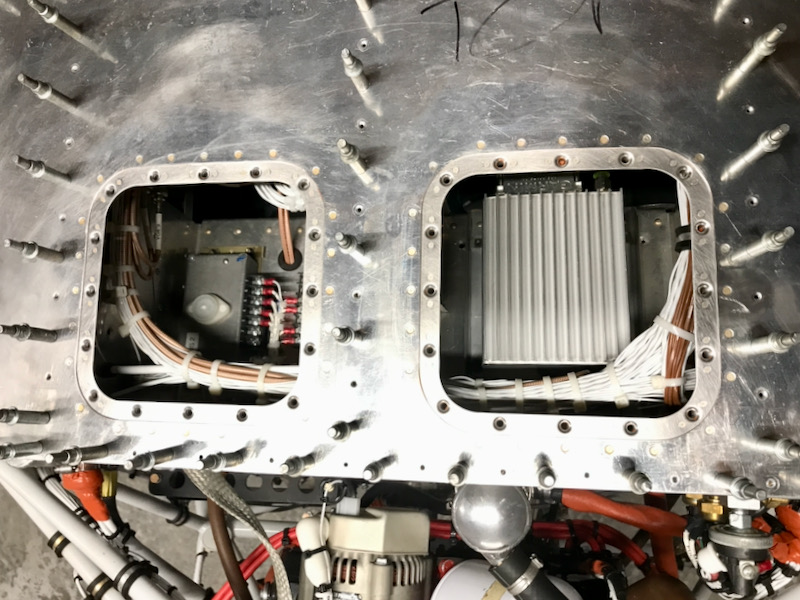

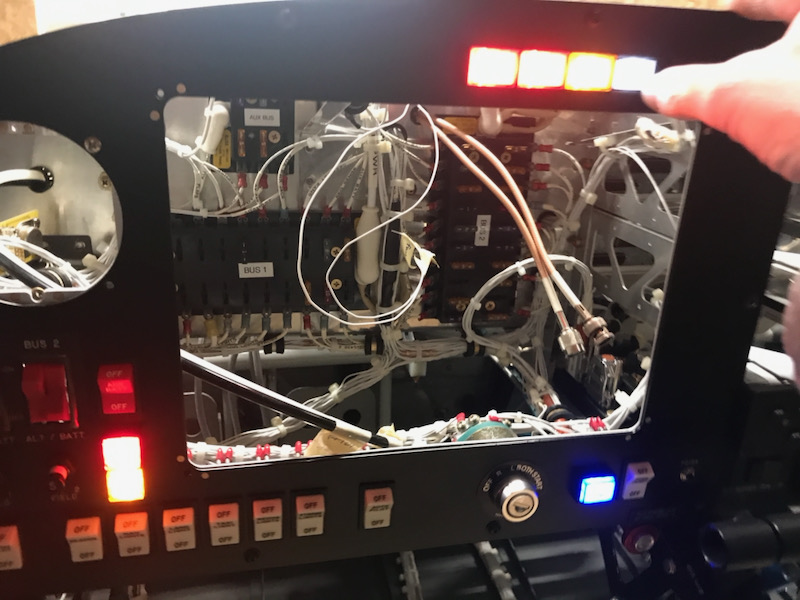

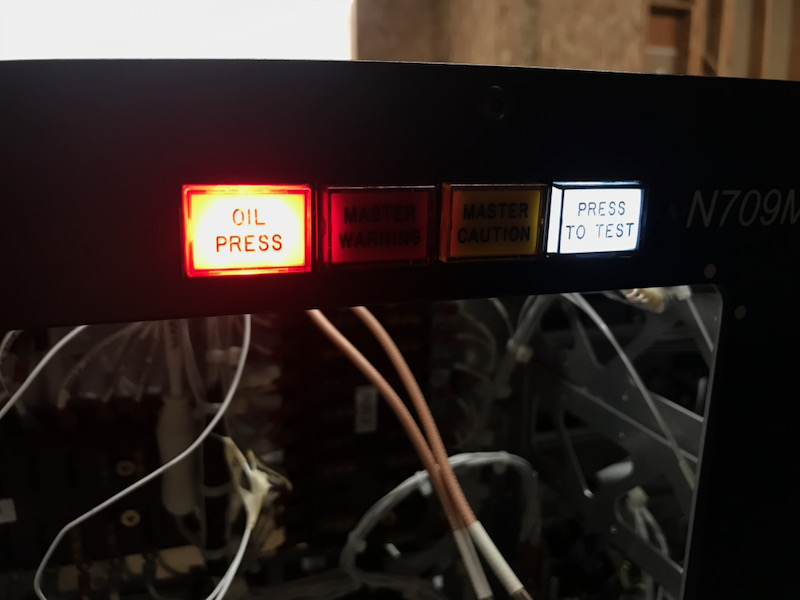

This picture shows where the fans are located in relation to the rest of the panel. The left-side fan will be easy to reach from underneath, and the right-side fan can be accessed by removing the audio panel and reaching up through the hole in the top of its tray.

I still need to crimp some connectors to plug these fans into the existing wiring, but that can wait till the next time I have the crimping tools out.