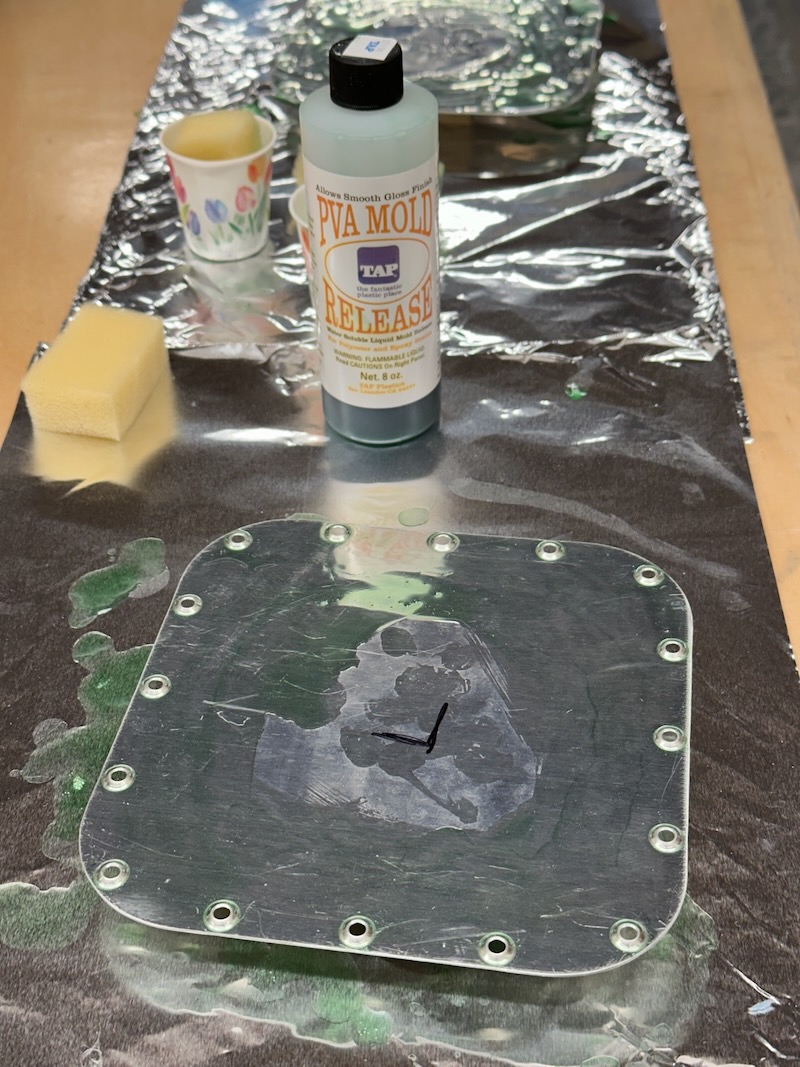

To seal the avionics access panels, I borrowed Dan Horton's idea for making rubber gaskets. First I used a sponge to apply a layer of PVA to the inside of the access panels, and let it dry overnight to a smooth film:

I stuffed the area under the access holes with aluminum foil to catch any sealant drips:

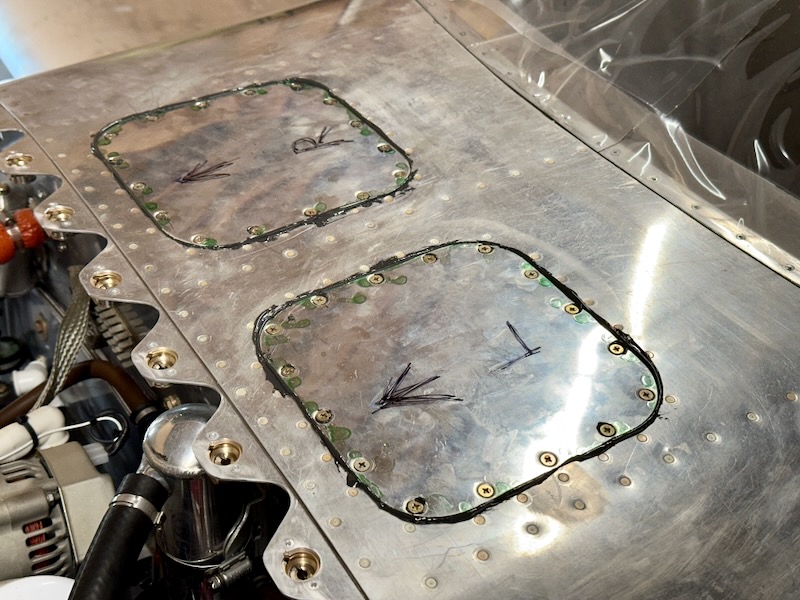

Then I applied a generous bead of proseal to the mounting flanges, and screwed the panels in place:

I used acetone to clean up all the squeeze-out, then left everything to cure for a week:

After I was sure the proseal was fully cured, I removed the screws and was able to gently pry off the access panels. The PVA film peeled off the aluminum and stuck to the proseal:

I used an xacto knife to trim off the excess blobs along the inner edge, and dissolved the PVA with a wet paper towel. Result, perfect gaskets that fit my access panels exactly:

If you are reading this and you are planning to install this kind of access panel in the future, I'd recommend adding a thin spacer (say 0.020"-0.032") between the fuselage skin and the mounting ring. That would allow for the rubber seals to be thicker and probably to work better.