At last, a chance to work on the airplane! Following much finagling, I managed to get the new fuel pump installed on the engine. It's pretty tricky to keep the thing aligned correctly and get the bolts started, while making sure the pump actuator lever isn't hitting the side of the pushrod way up inside the engine that actually drives the thing.

Not really visible here is the new gasket I installed between the pump and the drive pad. I couldn't get a torque wrench on the bolts – actually I could barely get a hex wrench on them with the engine installed on the airplane – so I just torqued them by feel and installed safety wire. It only took me about five tries to get the safety wire installed properly in the narrow space available.

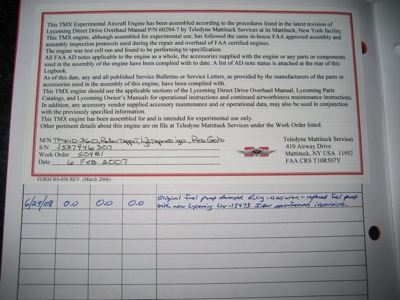

Since replacing the fuel pump seems like kind of a big deal, I decided to make an entry in the engine logbook. It says: 0.0 hours – Original fuel pump damaged during installation – Replaced fuel pump with new Lycoming LW-15473 in accordance with manufacturer's instructions.

With the fuel pump replacement finally finished, I was now back to where I was a month ago. The next step was to hook up all the hoses, but this time around I didn't want to use a steel fitting for the drain line and risk fracturing the pump again. I decided to use a brass fitting, but I couldn't find one that I could easily substitute for the previous one. Luckily, one of the things I learned when I owned an airplane with a car engine in it – besides the most important lesson, being for goodness sakes, don't ever buy an airplane with a car engine in it – was how to make aircraft and automotive plumbing play together. Here's some 3/16" I.D. automotive rubber fuel hose, a brass hose barb to pipe thread adapter, a brass 3/16" hose to 1/4" AN flare adapter, an AN818-4D flare nut, and some Oetiker stepless hose clamps:

Down at the bottom of the firewall, the rubber hose comes off the suspended plumbing contraption that carries the dumped fuel out the back of the cowling. I really like this method of adapting cheap rubber hose to AN plumbing. Of course, I wouldn't use it for anything other than a vent line, but it's easy to make and I think it looks more professional than the plastic ice maker hose the plans specify for this application. I already had the special tool needed to install Oetiker clamps, so no problem there.

The drain line attaches to the fuel pump via the hose barb fitting, and that's that. I also installed the other three fuel hoses (input, output, and pressure) and torqued all the fittings.