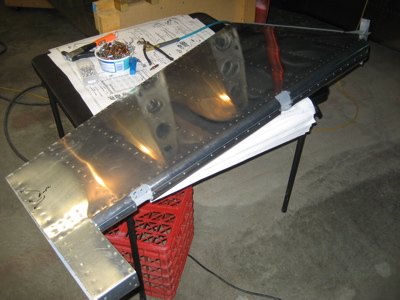

I took my replacement rudder over to John's place in order to make use of the five foot long back rivet plate he made. It made riveting the trailing edge pretty easy. First I set the rivets partway with the back rivet set, then flipped the rudder over and finished them off using the mushroom set.

Here's another one of those photos that shows I really built the airplane. Also that I shill for the Boulevard corporation on laundry day.

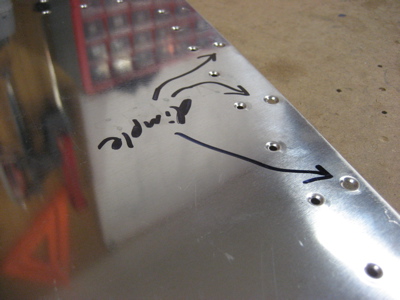

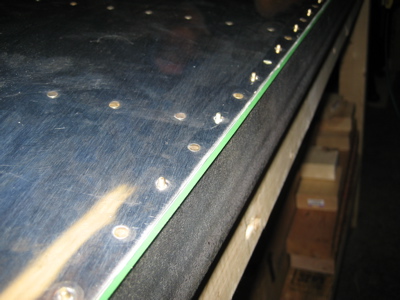

I alternated the rivet directions because I'm anal like that.

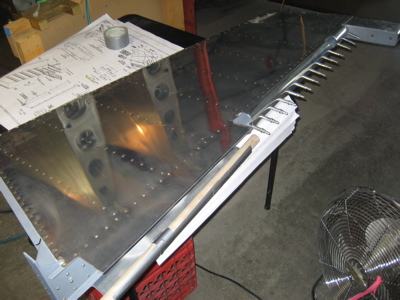

Then while we had everything set up, Chad and John finished off the trailing edge of John's rudder:

Two rudders completed!

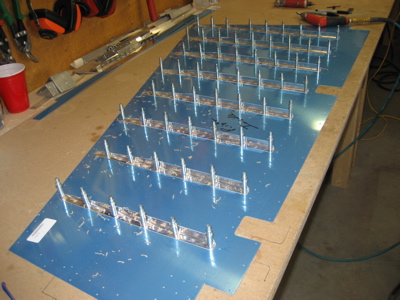

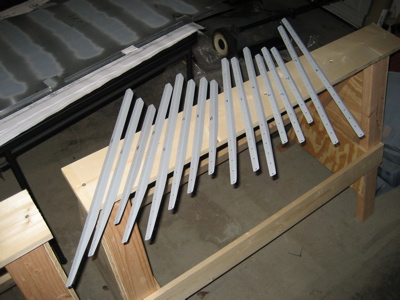

After I brought the rudder home, I set about rolling the leading edge:

Done! I'm happy with the rudder now. Whew. The very long back rivet plate is an excellent way to do it, at a total cost of about $24 worth of steel angle and machine shop work.