Another month without much work on the airplane. I have an excuse, though: it's been really cold in my garage!

I have a whole list of wiring chores left to complete, but I need to take a break from running wires through the fuselage before I go cross-eyed. I thought I might work on some firewall-forward tasks for a while, which will actually help with wiring in a roundabout way; before you can do much wiring forward of the firewall, you need to finish the baffles, which means you need to fit the cowl, which means you need to fit the spinner (the pointy bit on the very front of the airplane), which means you need to fit the propeller. Plenty of work to do there.

The plans suggest making a spacer out of wood or PVC to stand in for the propeller, but since the consequences of getting the cowl/spinner gap wrong are so ugly to contemplate, lots of folks end up using a real prop instead. However, instead of using my very expensive propeller as a fitting template, I had the idea to use a junked prop hub instead – that way there's no questions that the dimensions will be right.

I put out a call for an unairworthy Hartzell prop hub to use for fitting the cowl and spinner, and received the following hunk of grungy aluminum from a generous forum member (thanks, Joe!). It's only the rear half of the hub, but that's all I really need anyway. It is the older C2YK model instead of the C2YR that I have, but the critical dimensions for spinner-fitting are the same.

A little solvent and elbow grease cleaned it up pretty well. The key metric here is that we want to avoid leaving a big grimy smear on the clothing of any wives who happen to be walking through the garage. It just seems like everything will go so much more smoothly that way.

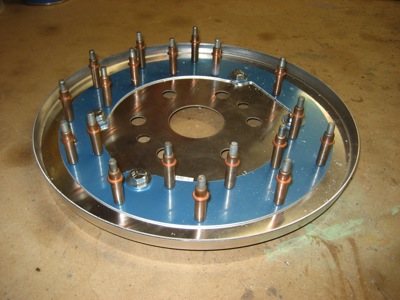

Digging into the pile of remaining airplane parts, I pulled out the rear spinner bulkhead and its associated doubler ring.

As I expected, the spinner bulkhead is noticeably dished, although it appears to be otherwise true and symmetrical. This appears to be a common occurrence, so I will probably just ignore it.

With some hardware-store bolts, I temporarily attached the doubler to the bulkhead:

…then drilled and clecoed the holes for the rivets that will eventually attach these two pieces together:

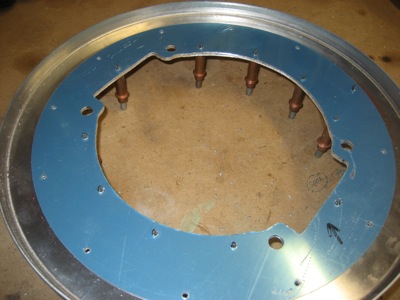

If you have a Hartzell prop like I do, you need to cut out a significant portion of the spinner bulkhead. I transferred the shape of the hole in the doubler ring:

Initial cuts were made with my air nibbler, which is great for this kind of work. Going slowly and carefully, I was able to get within 1/8" of the line.

Then it was time to file, file, file. The corners look lumpy here, but that's how the cutout needs to be in order to clear the prop hub.

More filing and finish work… I made plenty of aluminum shavings.

I spent a lot of time making sure all the edges were well and truly deburred.

I need to prime these parts before I rivet them, but it's way too cold and dark outside to do that, so it will have to wait on the weather.

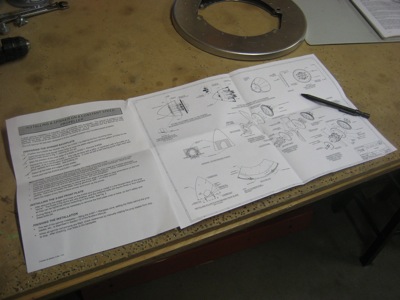

Also: What are these?! I haven't looked at the plans for over a year, I think… ever since I got to the step that said something like "Now might be a good time to think about wiring and an electrical system, if you want one."

And speaking of the spinner backplate… I realized that this piece will literally be moving the fastest of any of the parts that I've fabricated: in addition to however fast the plane is moving through the air, the perimeter of the 13" diameter spinner will also be doing about another 100 mph as the crankshaft is turning at 2700 RPM. Neat.