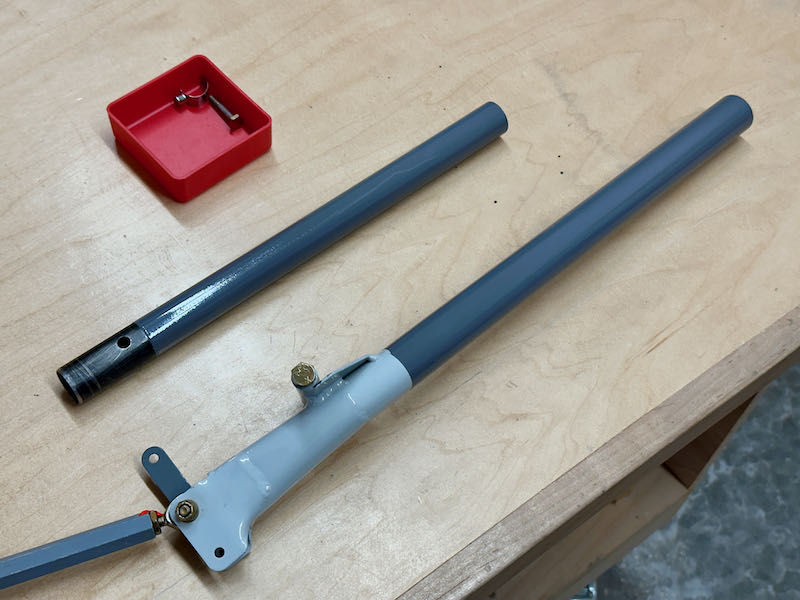

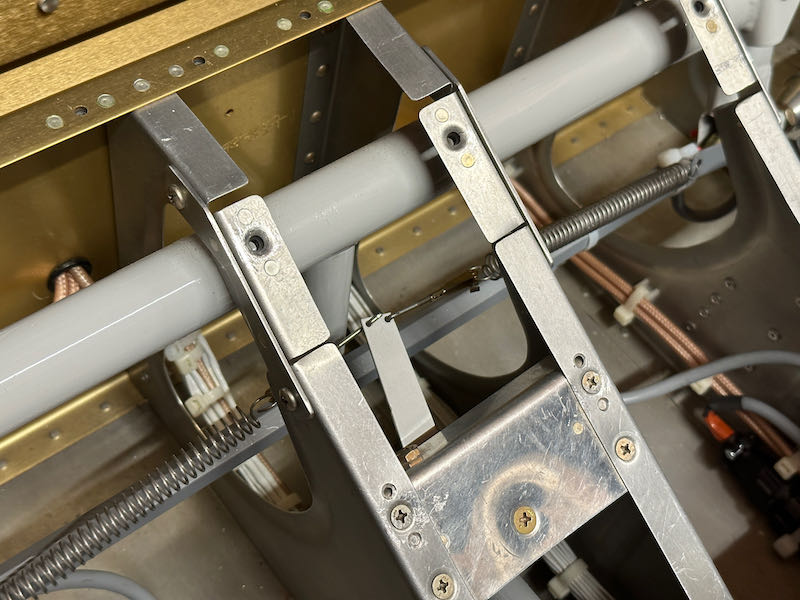

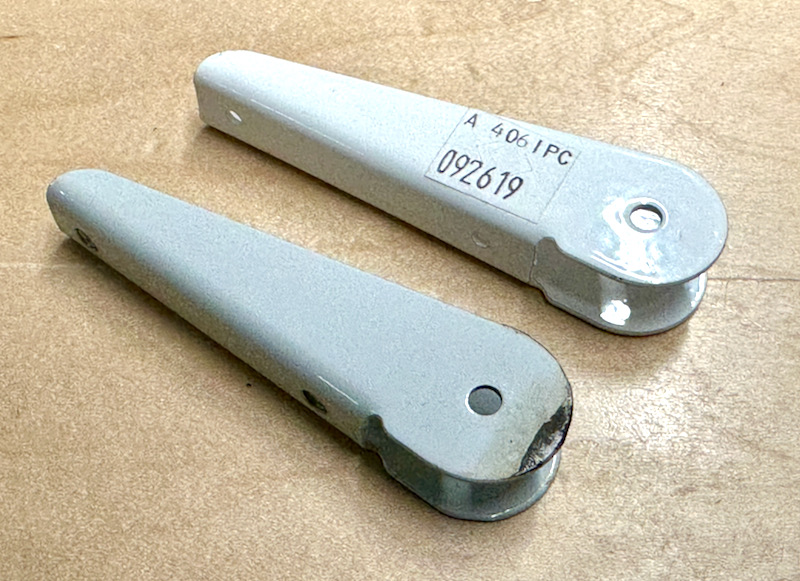

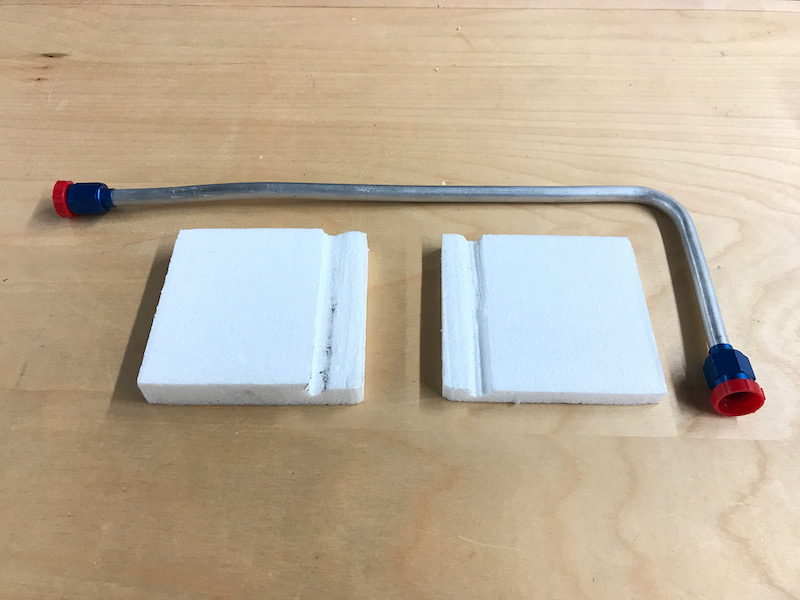

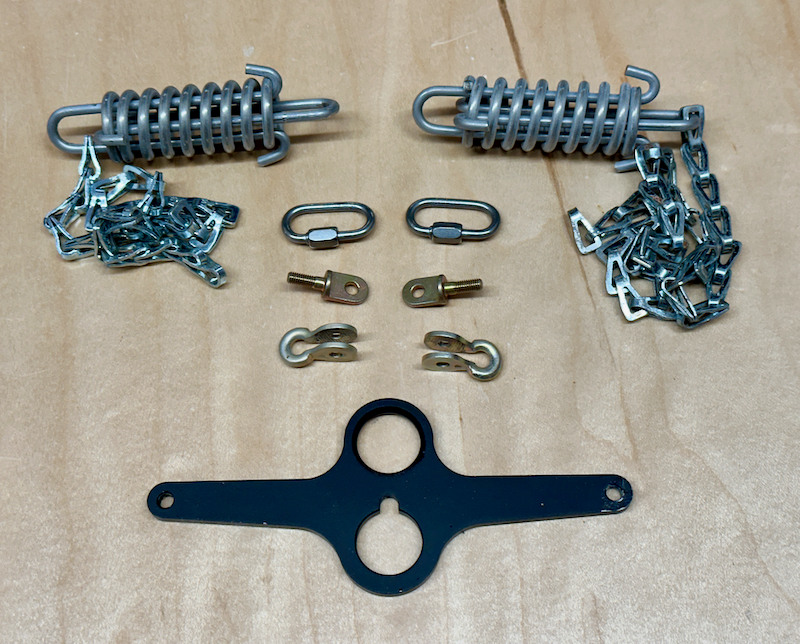

After trimming the flaps to fit nicely to the fuselage, the next step is to finish the mechanism that operates them. The RV-7 plans have you make a pair of pushrods by tapping the ends of some fairly skinny aluminum tubing, but I decided to follow in the footsteps of others and use the beefier hex stock normally used by the RV-9. Since the RV-7 uses shorter pushrods, the easiest way to do this was to simply buy the RV-9 parts and cut them to the correct length:

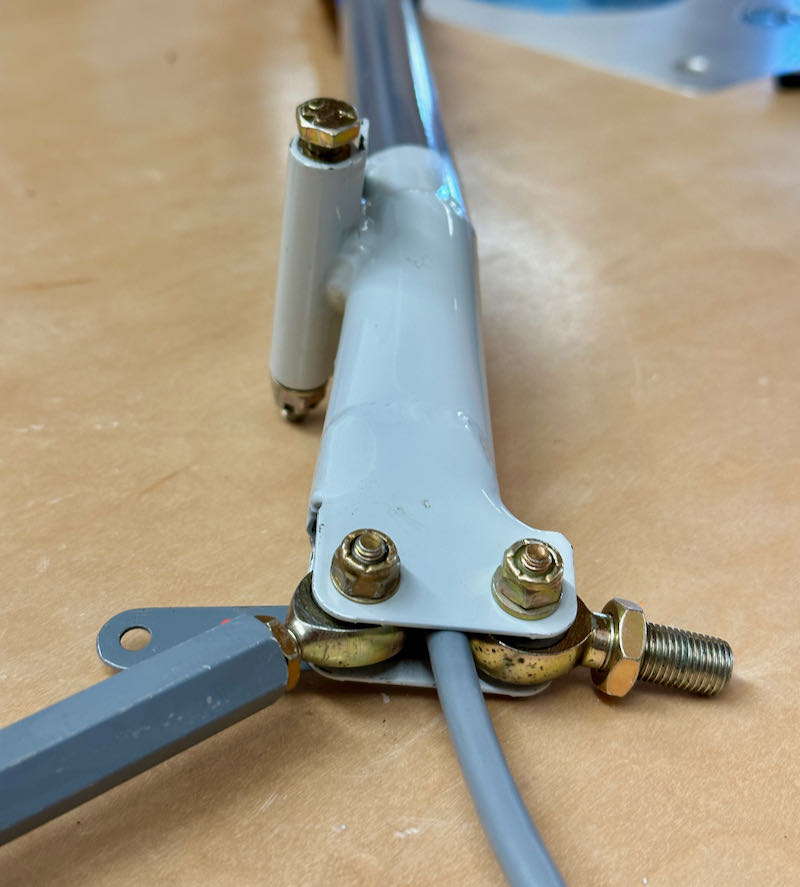

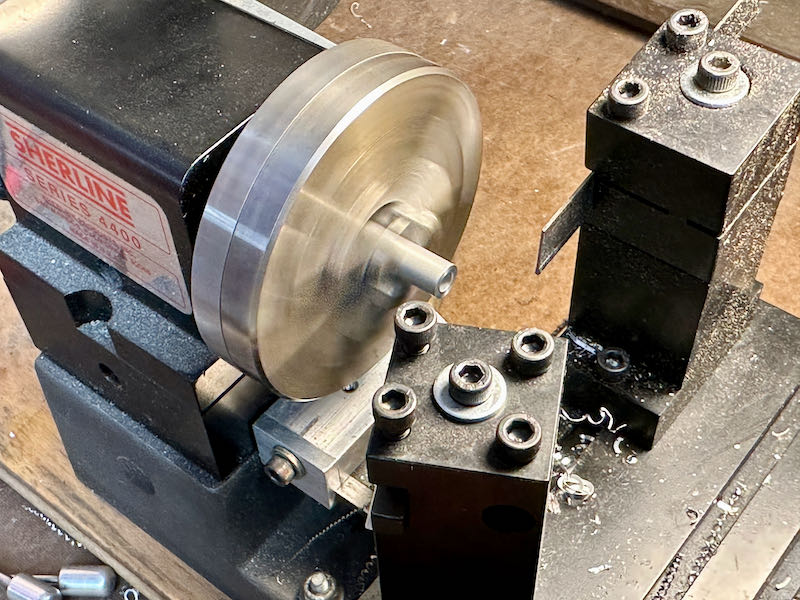

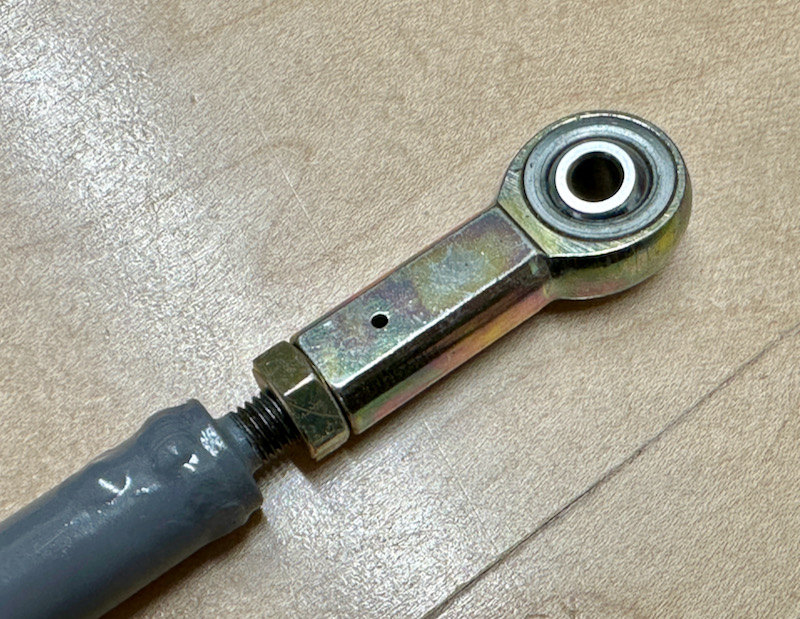

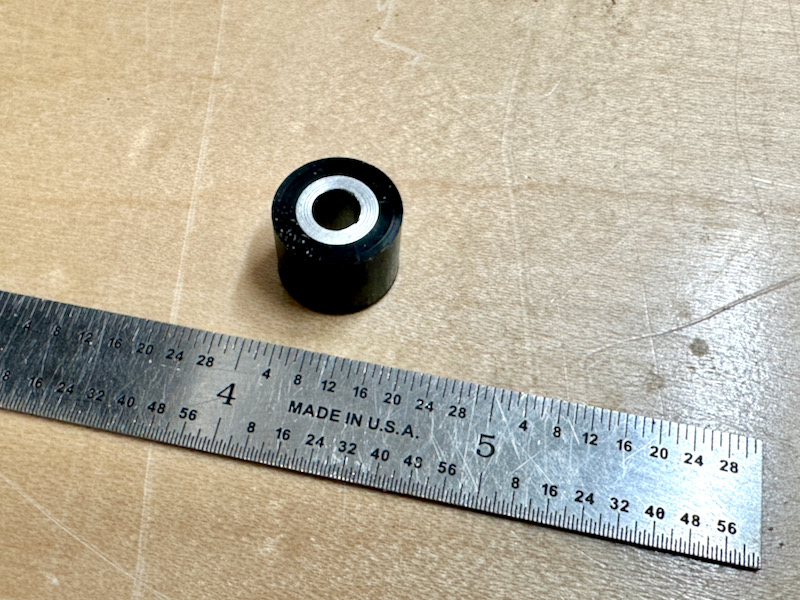

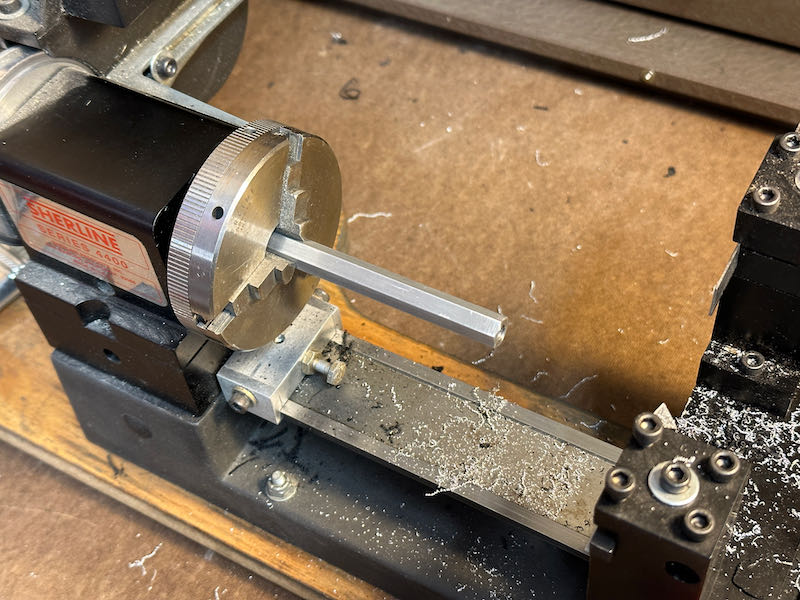

Real machinists are cringing at the unsupported length in the above photo, but since I didn't have a good way to support these pieces while facing the ends, I just took light cuts and worked carefully. Here's a finished pushrod with one rod end bearing installed:

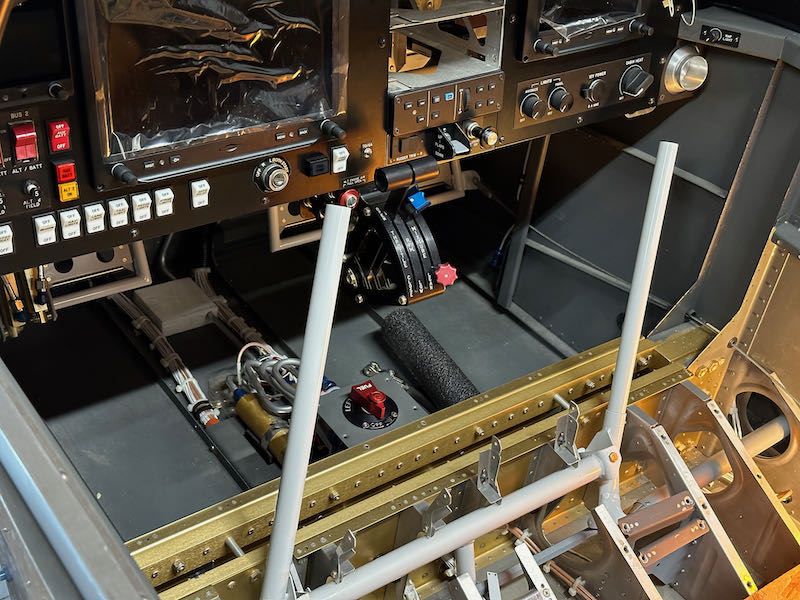

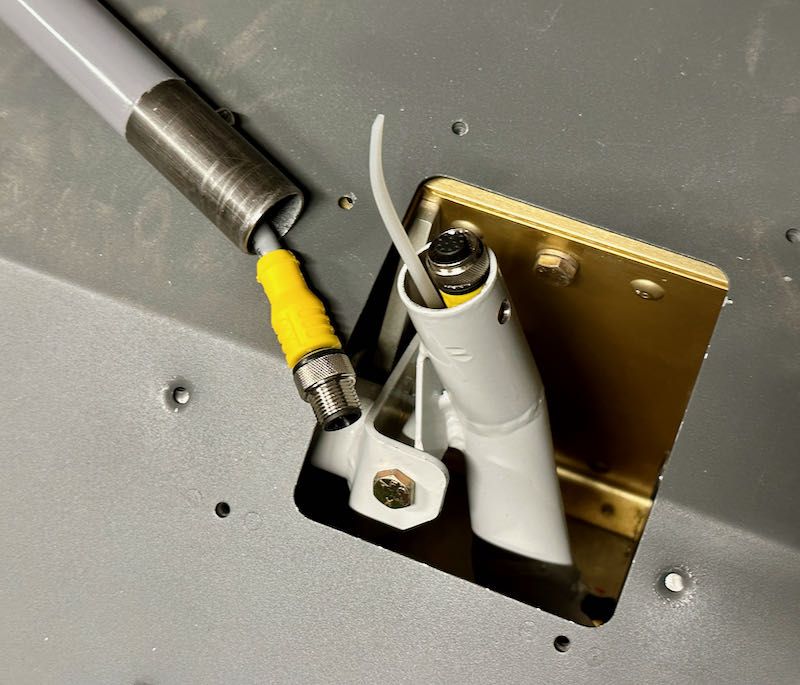

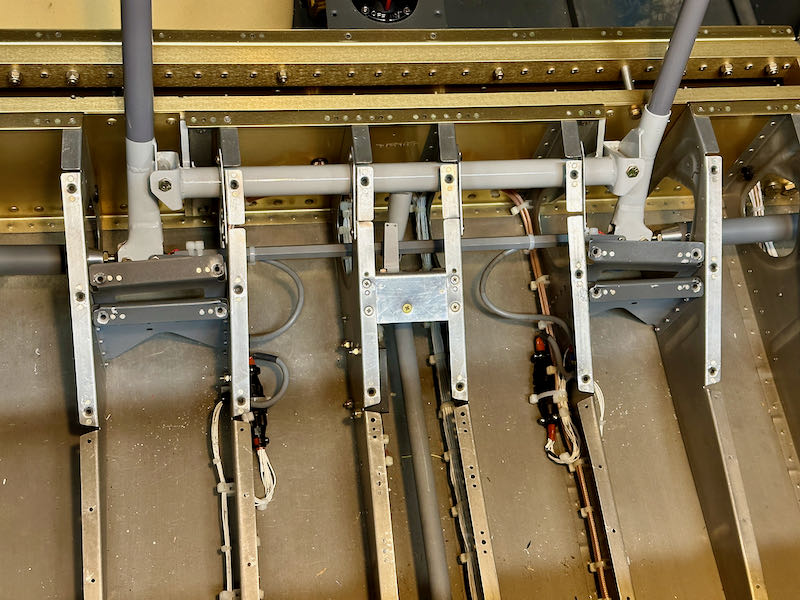

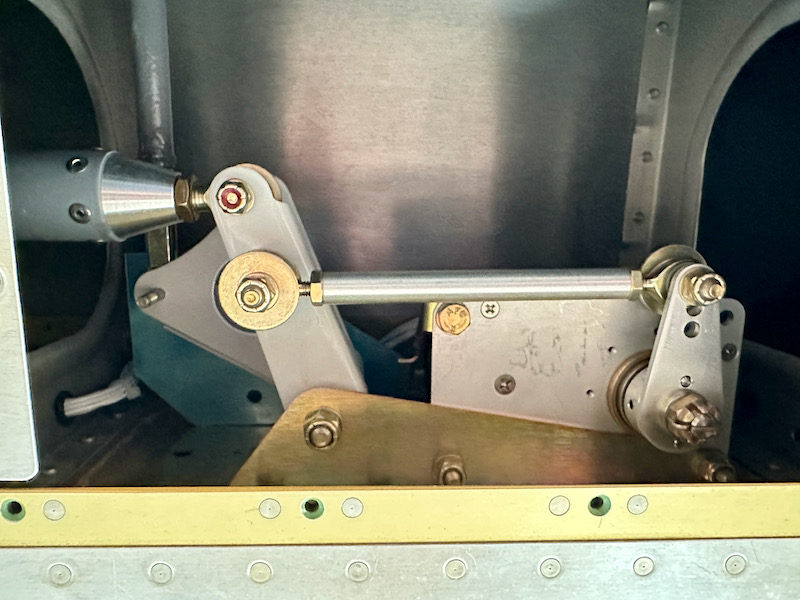

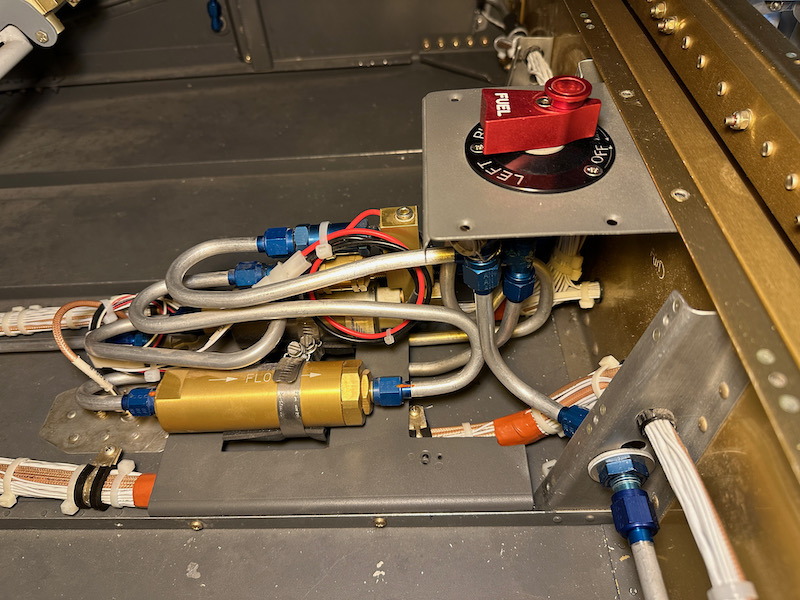

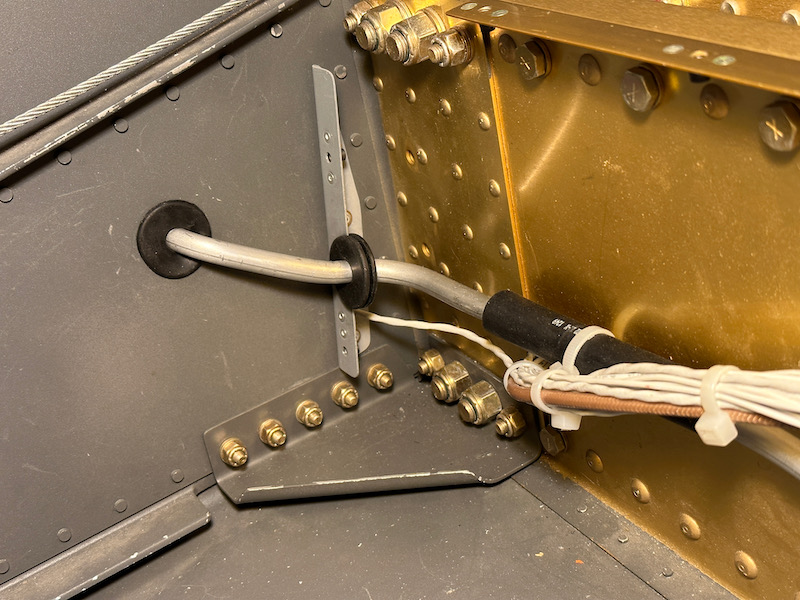

The most challenging portion of this part of the project was cutting the holes that allow the flap pushrods to pass through the fuselage bottom and sides without binding. I'm told that these are prepunched on the RV-14, which must be nice, since they have to be a strange 3D shape that can only be determined iteratively. I didn't take any pictures of the process, but there was a lot of tedious test-fitting, marking, and grinding until I achieved a satisfactory result:

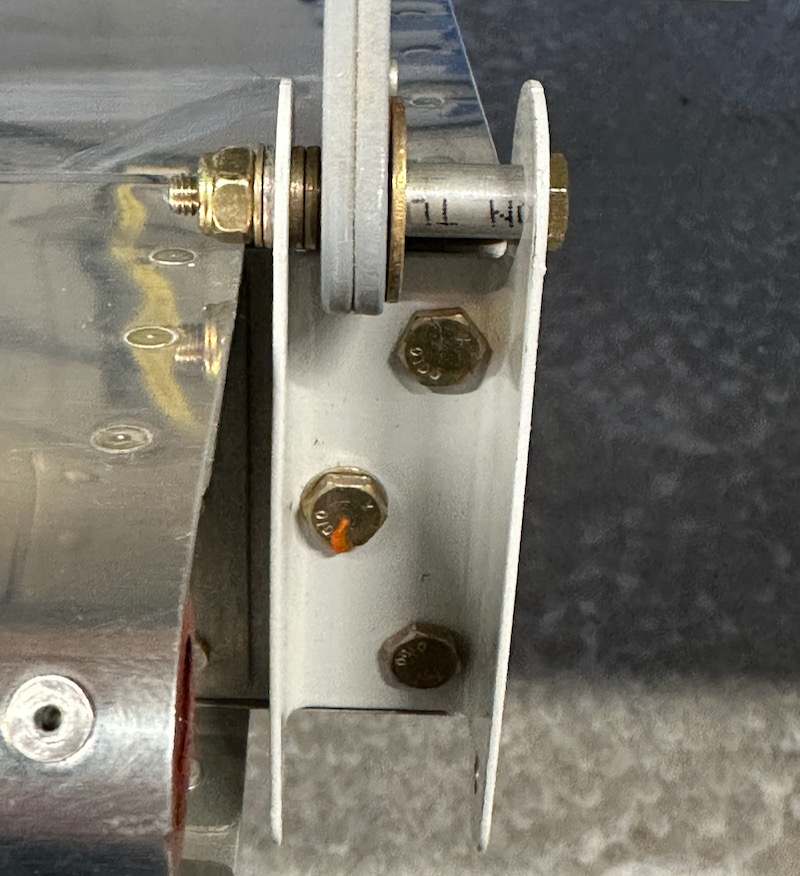

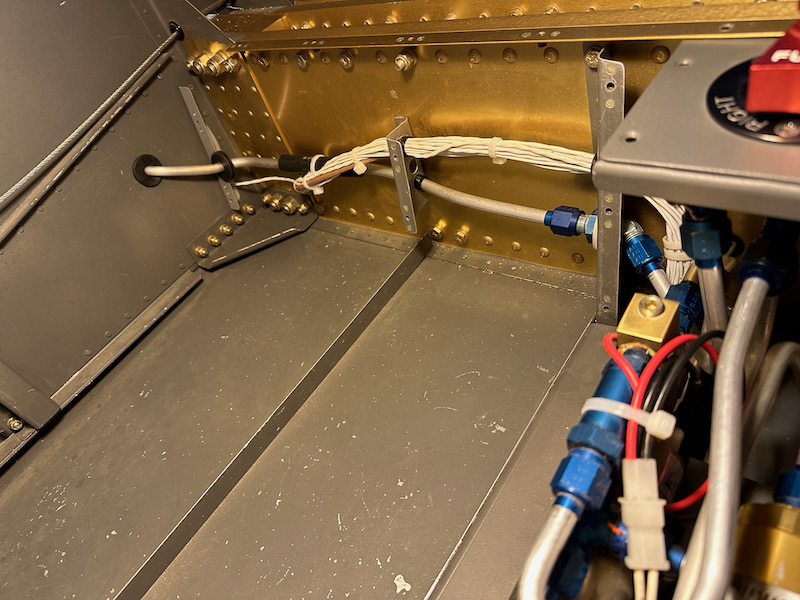

Here's a view of the same hole from the inside looking down. I still need to clean up the mess of aluminum dust and sanding-wheel particles from inside the fuselage:

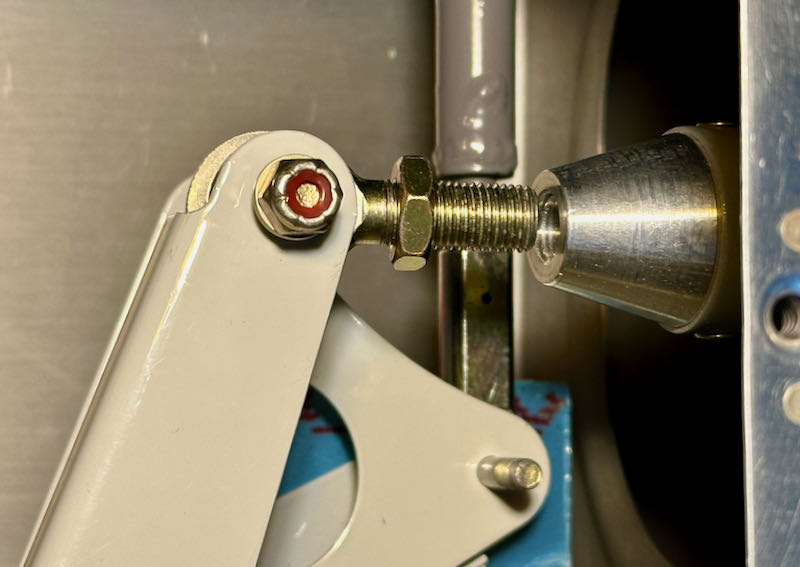

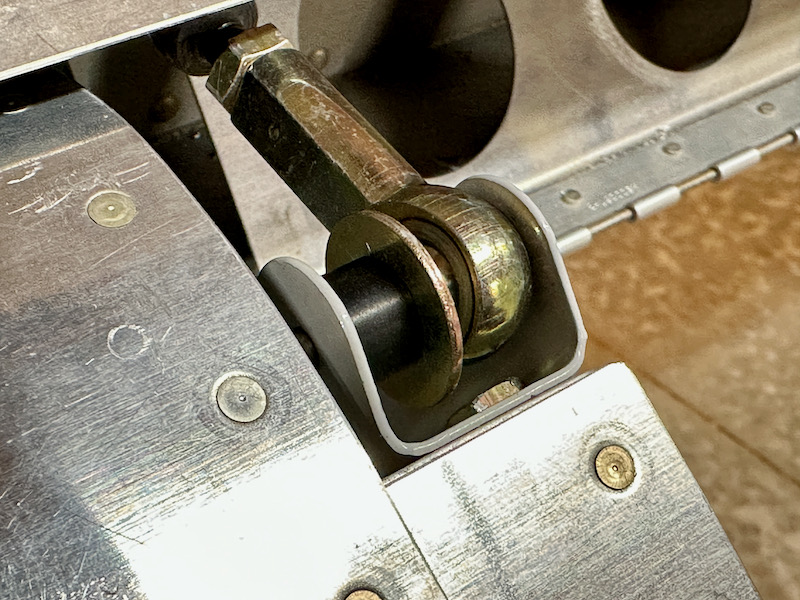

I must have installed and removed this pushrod a hundred times before I got the shape of the hole right. Here you can see that there is adequate clearance all around when the flaps are in the full-down position:

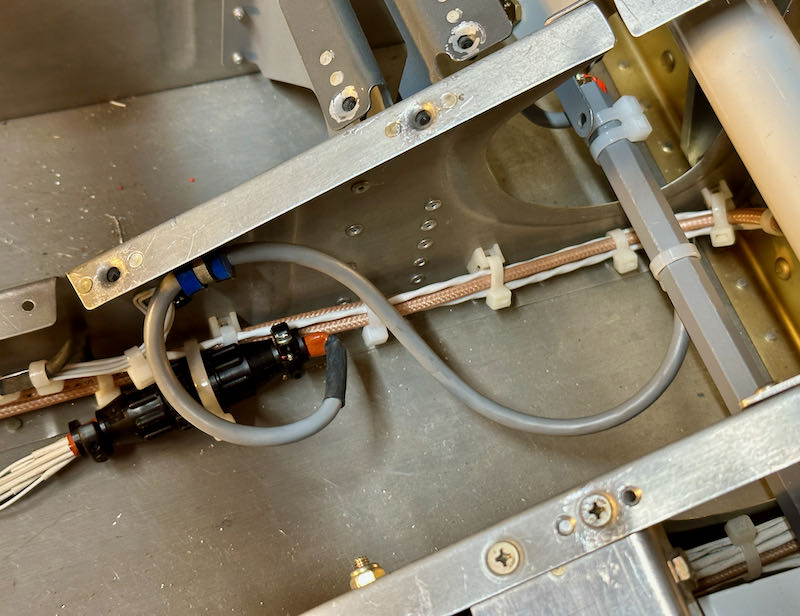

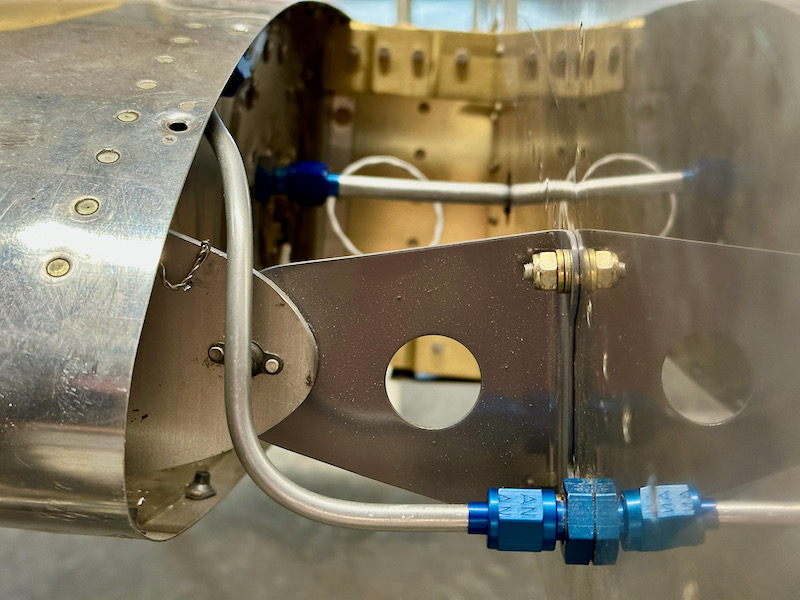

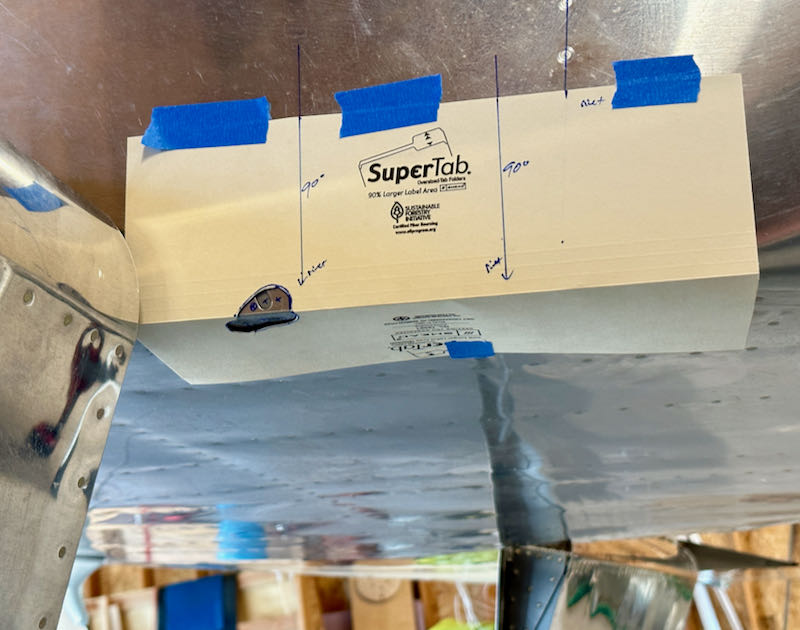

Finishing the first first hole took me an entire day and then some. Instead of starting from scratch on the second hole, I used a piece of manila folder to make a rough template that would give me a head start:

Here's the second hole, which only took me a half-day to finish. The blue line indicates where the flap bottom skin ends, showing that the hole will be completely hidden when the flaps are up:

I have to say, this whole pushrod-hole situation seems like a real afterthought to the design, and the way they have you grind your way through the corner of fuselage is pretty barbaric. And I'm not just saying that because I slipped with the sanding drum and scuffed up the fuselage skin:

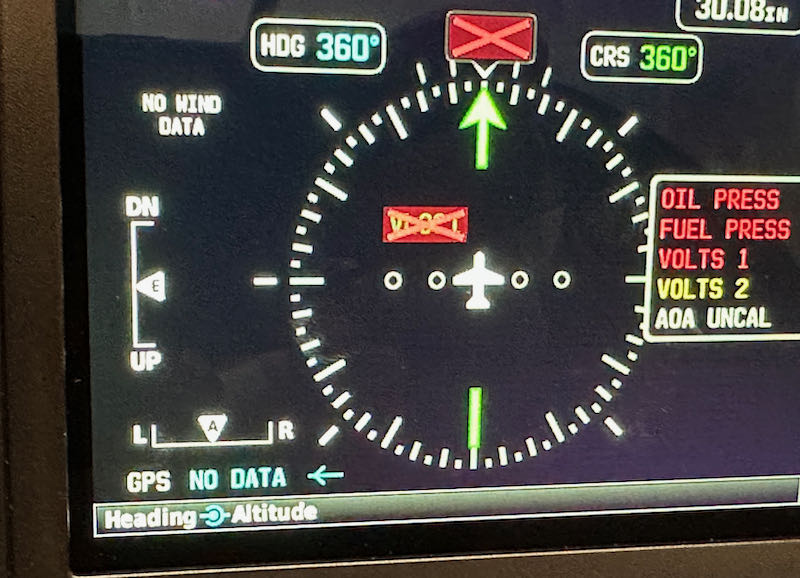

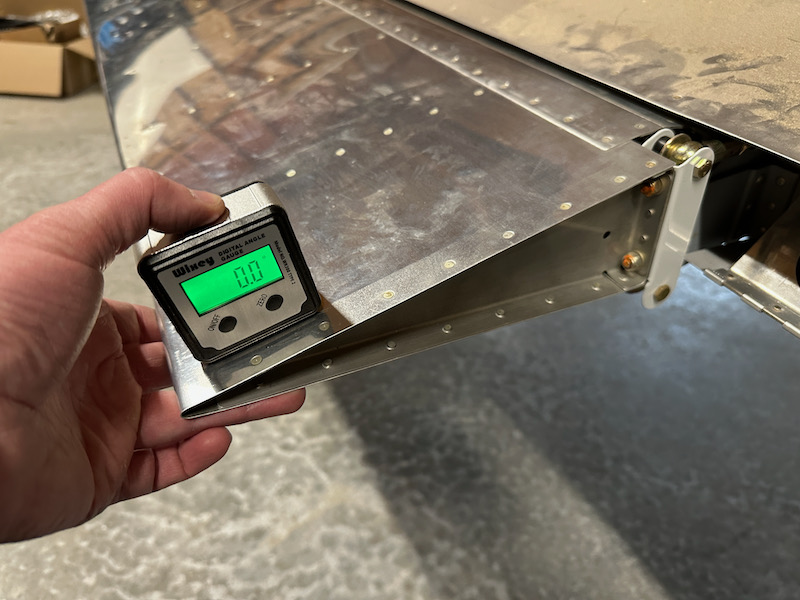

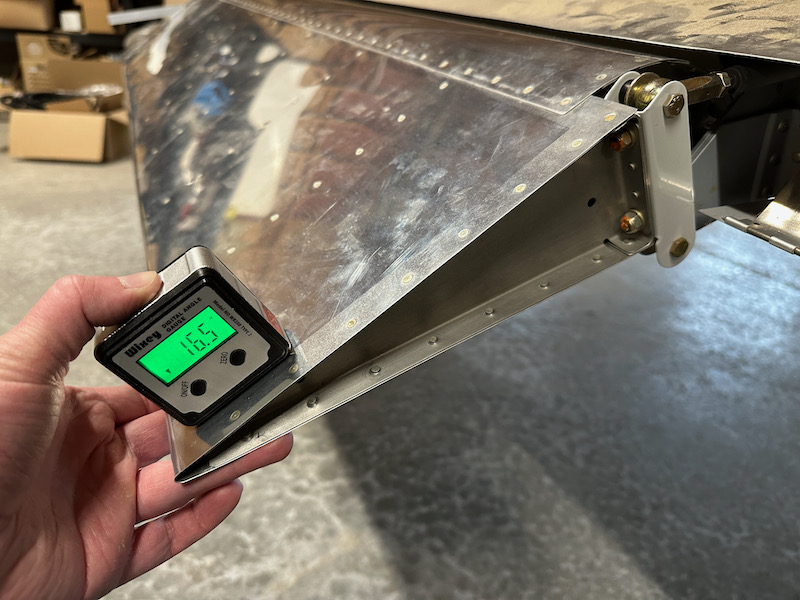

The plans list the flap travel limit as "40-45 degrees maximum", which is less than precise, but I don't think there is actually much adjustment possible with this mechanism – you just have to take what you get. In my case I am right at 45 degrees at full-down, which is acceptable. I haven't hooked up the flap positioning system yet, so this may be reduced slightly in the future.

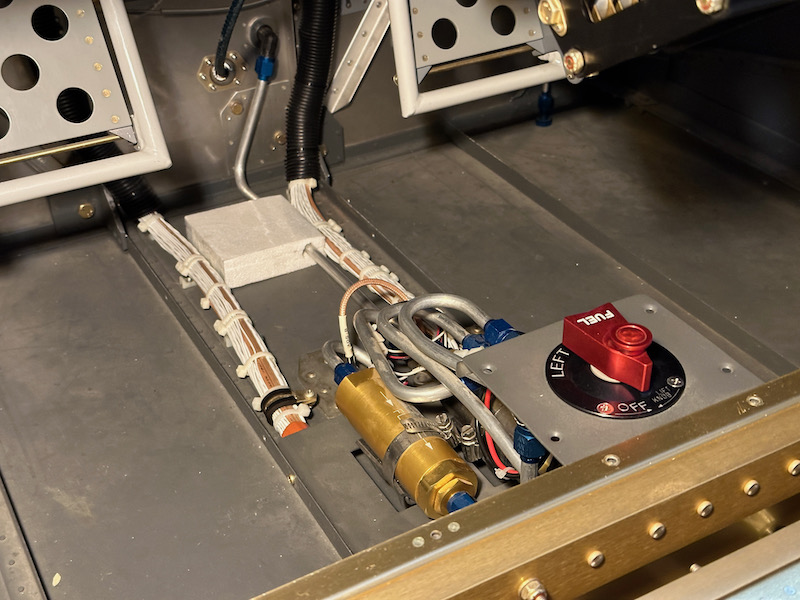

I don't want to install the flap mechanism permanently quite yet, and I don't want to damage the flaps while crawling in and out of the fuselage carrying tools, so I removed them from the wings and set them aside for now. While I have improved access to the lower rod end bearings, I removed and reinstalled them with lock washers and blue Loctite in accordance with the plans:

Still some work to be done before the flap system is truly finished, but it was neat to be able to hook up a battery and watch the flaps go up and down.