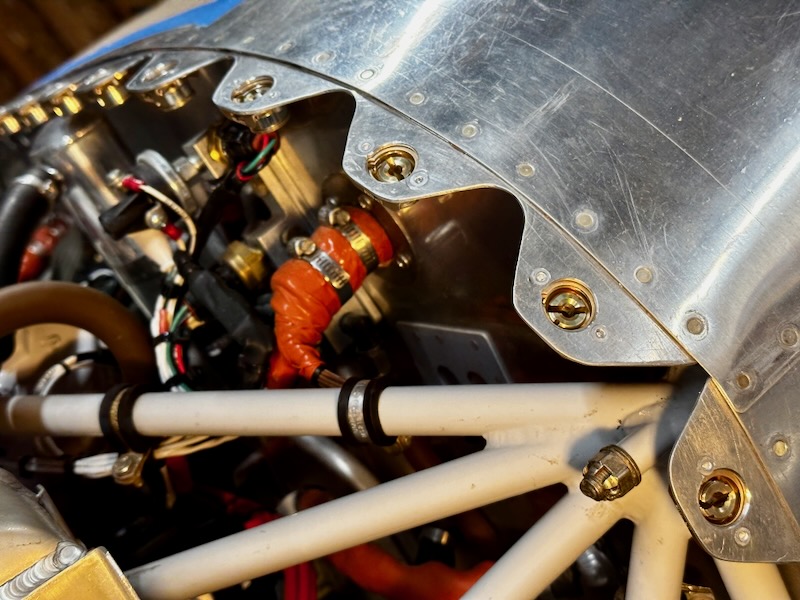

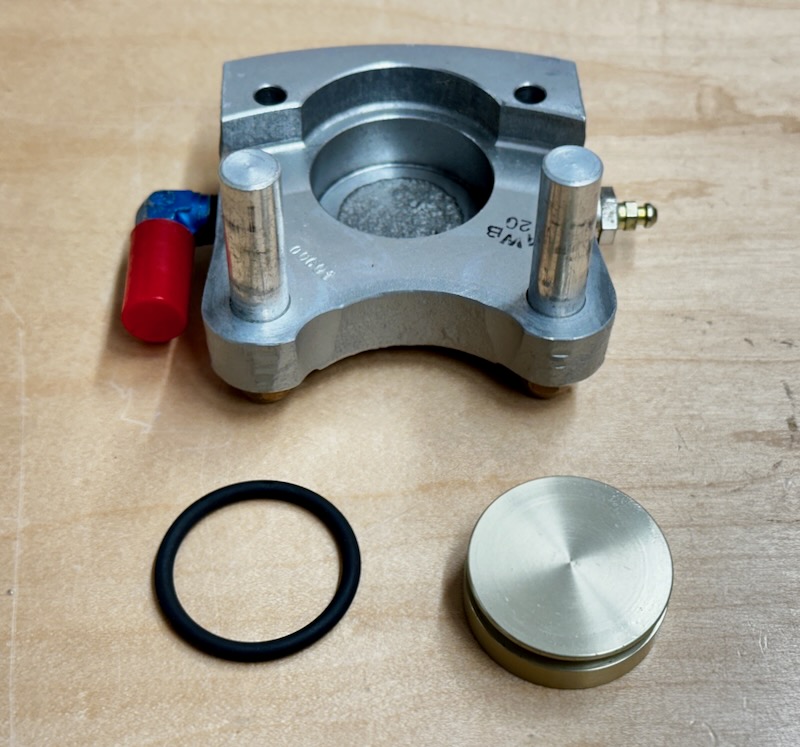

Before filling the brake system with fluid, I removed the calipers and took out the pistons so I could install improved o-rings. These are necessary to take full advantage of the higher-temperature brake fluid available these days (MIL-PRF-83282D) and were quite difficult to find in small quantities in the correct temperature rating of -40º to +400ºF. I ended up ordering them from Van's, which took a while due to their current difficulties. I lubed the new o-rings and the caliper bore with silicone before installing.

It's funny that this is all the brakes you get to stop nearly a ton of airplane traveling at highway speeds. Small wonder I chose to use high-temp brake fluid, since these can get really hot under heavy use.

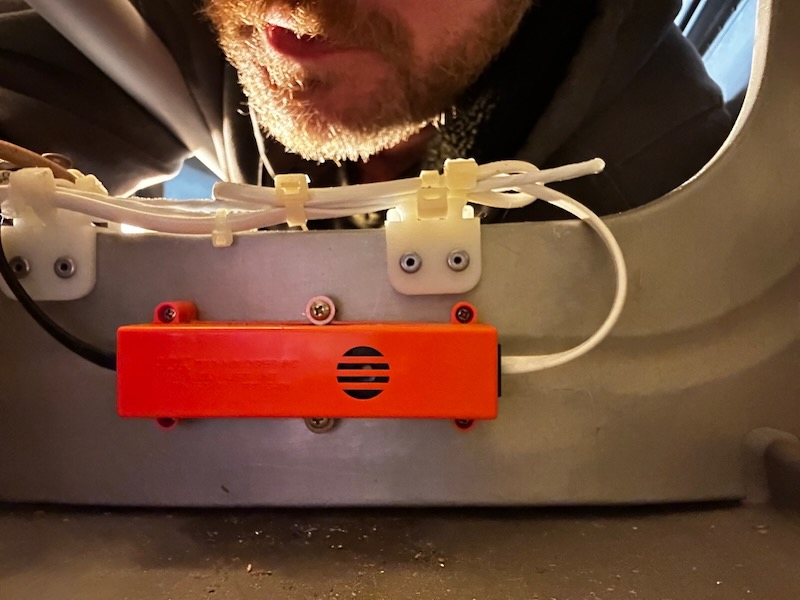

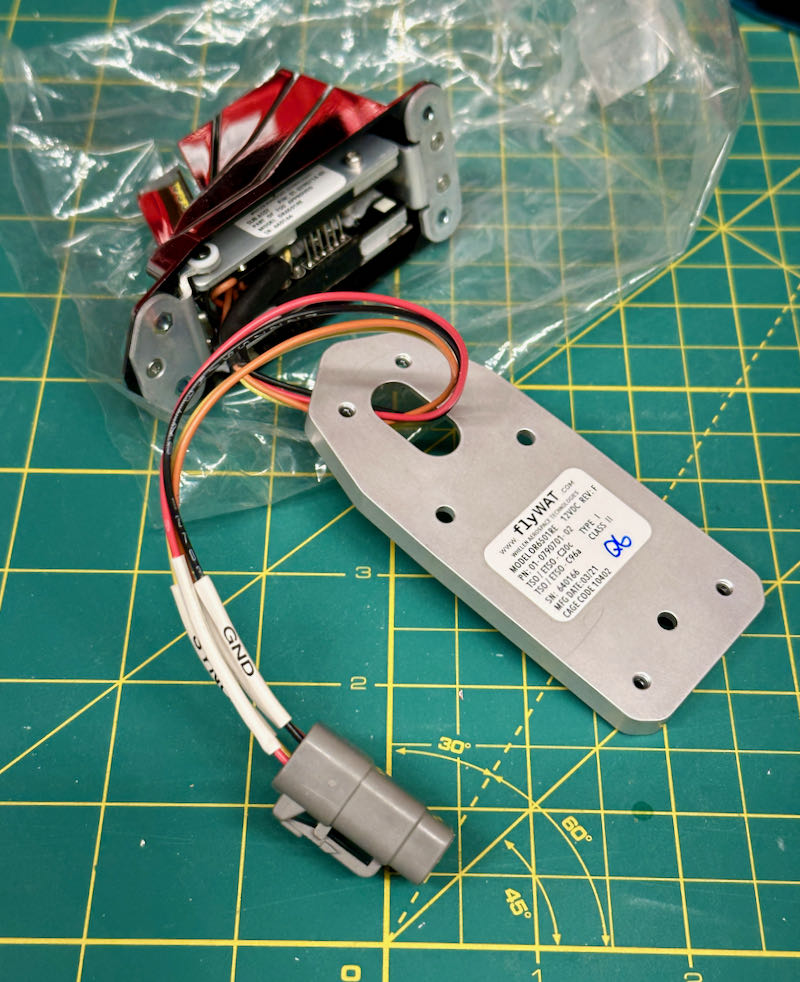

To bleed the brakes, I cobbled together this contraption from a small pump oiler and a special adapter designed to go on the bleeder fittings:

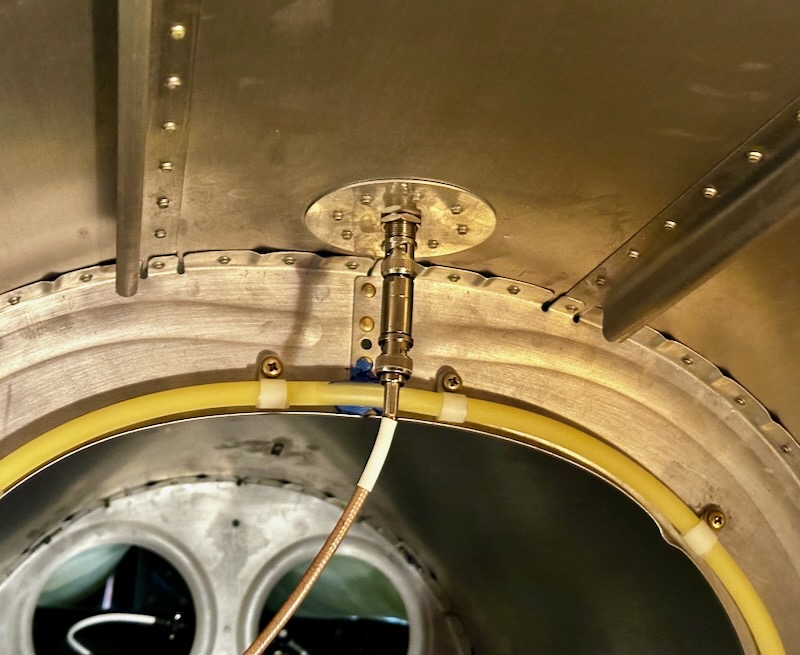

To catch the overflow from the brake reservoir, I plumbed a catch can using a coke bottle and some brass fittings. Additional details of how this works can be seen in the photos below:

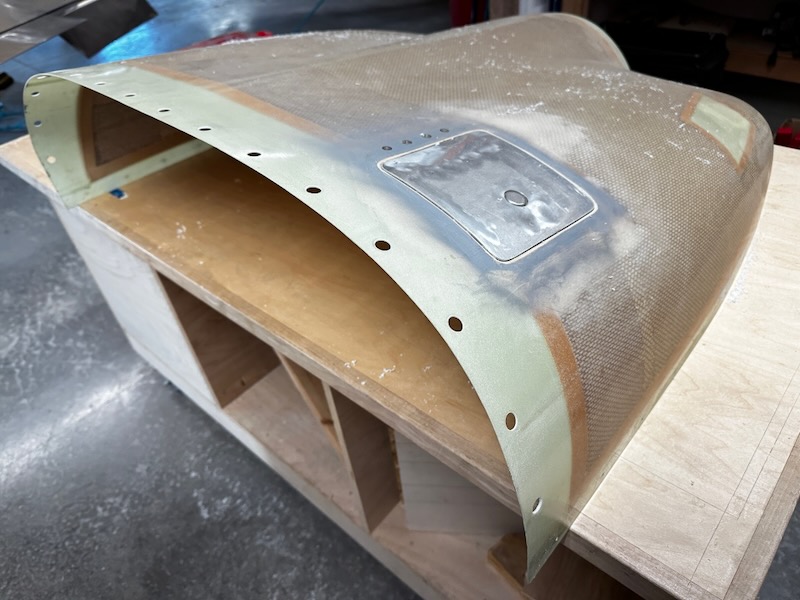

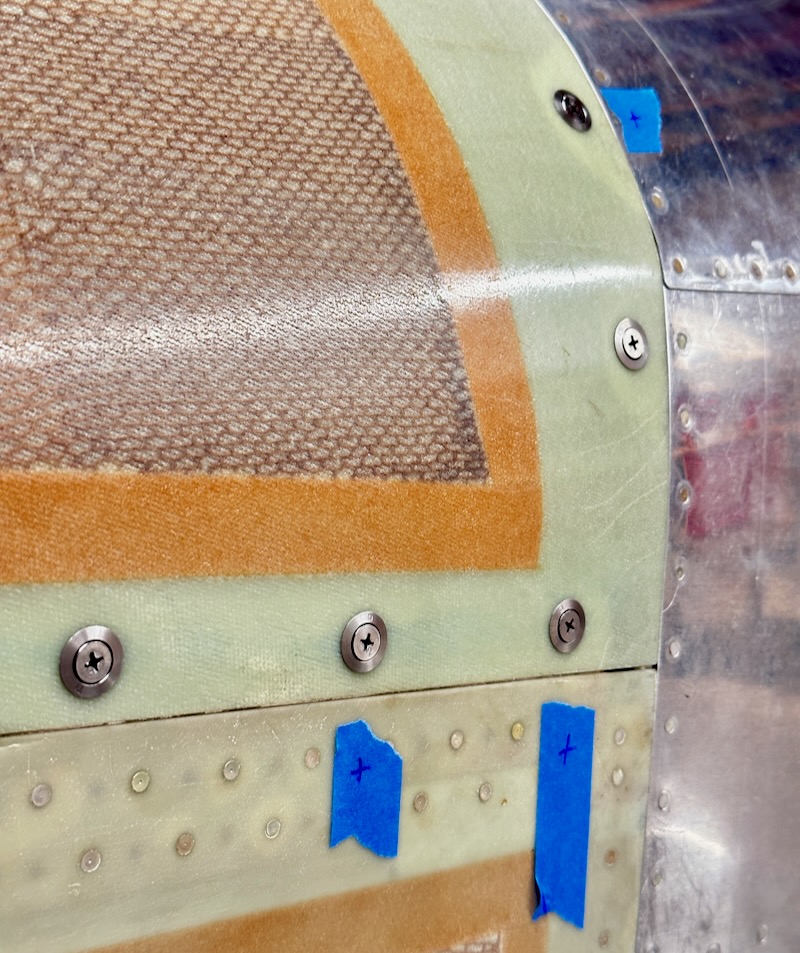

Before starting, I put down some old t-shirts under all the potential leak spots, to hopefully keep the floor clean:

I recruited a friend to help pump brake fluid while I crawled inside checking for leaks and tapping on things to clear out air bubbles. Happily we had no leaks and – I think – ended up with a solid result. We went through a lot of paper towels and rubber gloves, and didn't take any pictures during the process, but you may assume it was messy despite our best efforts to be sanitary about it.

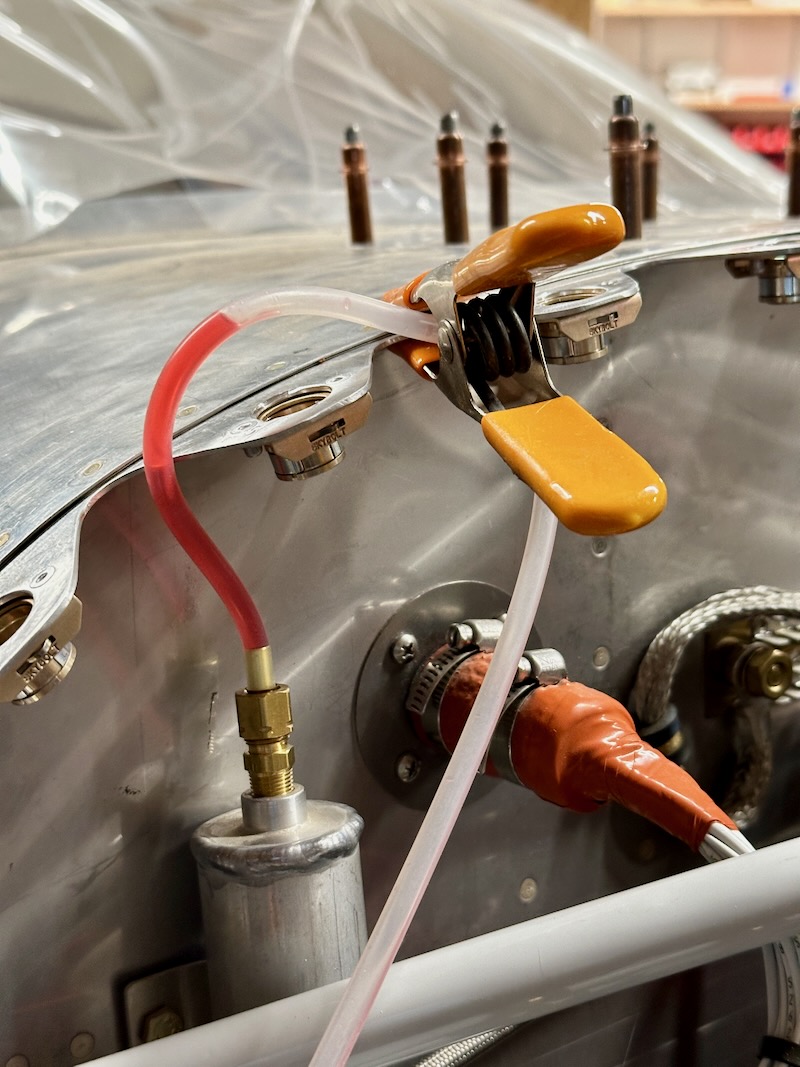

Clear tubing at the top of the reservoir allows air bubbles to be pumped out. We kept pumping fluid until the brakes were solid and bubbles stopped appearing in the tube:

The end result was a reservoir totally filled to the top, which is fuller than it needs to be. I used a syringe to siphon out about an inch of fluid before installing the vent cap.

All the accessories are stored inside a messy plastic bag for future brake work. From the quart can of brake fluid I opened, I ended up with about a pint left over, which is stored in a mason jar I stole from my wife's canning supplies.