One component that I've designed into the electrical system of my airplane is a small auxilliary battery, which will help keep a few critical systems online during engine start. Unfortunately there aren't a great many places where you can easily mount a second battery. I thought for a while about putting it under the baggage compartment floor or even under the seats, but in the end I decided to choose a small battery and mount it to the F-721A forward canopy deck, behind the panel on the passenger side.

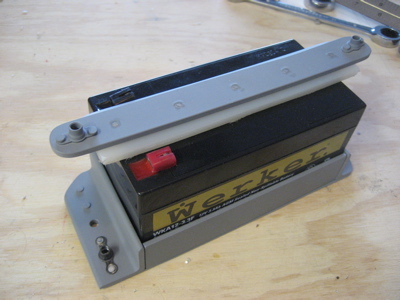

I went to the local battery mega-store and picked up this 3.3 Ah VRLA battery. It is a store-brand clone of a Panasonic LC-R123R4P and is the same size, so I should be able to get replacements in the future if I need to. This is a pretty small battery (note the tape dispenser for reference) but it's the biggest one that will fit between the panel and subpanel.

I fabricated some parts out of scrap…

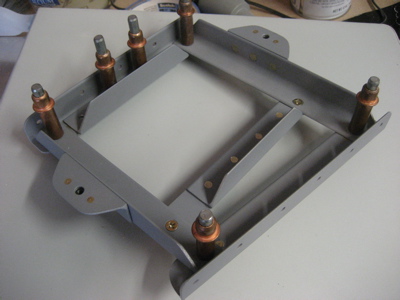

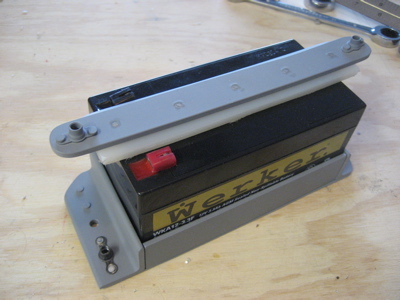

…and made this simple battery box. The base is 0.050" alclad, with 1/8" angles riveted to it (double-flush where necessary). It's probably way overbuilt, but I just used the materials I had on hand. I'm not sure why I primed it – force of habit and superstition, I guess.

Just like the main battery box, this one features a bar to hold down the battery. Unfortunately the battery's terminals are both on top, putting them close enough to the hold-down bar to make me worry about them shorting to it. I worked around this by riveting the bar to a strip of 1/4" nylon that is wider than the bar is, this preventing the bar from being able to contact either terminal. I'm not sure why I had nylon sheet stock in my junk bin, but I'm glad I did.

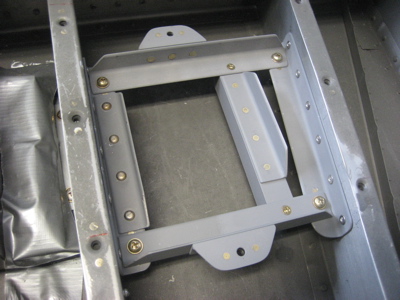

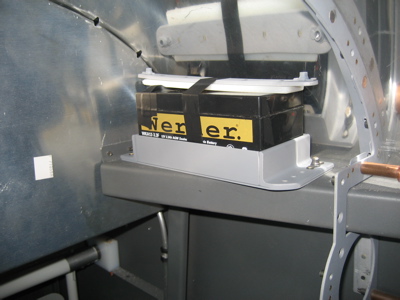

Here's the box bolted in place, with the hold-down bar temporarily taped on until I can pick up some long bolts of the correct size. Note that the bolts all come up from the bottom – this is because the fuselage skin prevents you from lifting the battery straight out of the box. To remove the battery, you actually have to undo all four bolts and slide the whole battery box out first. Hopefully this won't be too much of a hassle, as I don't anticipate needing to replace this guy more often than every few years.

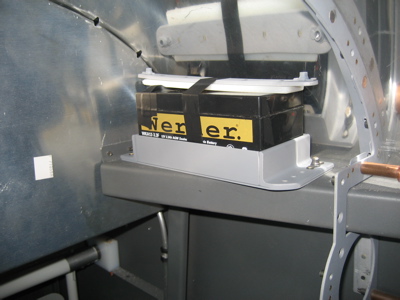

Here's what it looks like with the skin clecoed in place. There is about 1/8" of clearance between the skin and the aft corner of the battery, which explains why I had to let the rear hang off the F-721 a little bit.

After I took this picture, with the skin still clecoed in place, I unbolted the battery box and removed it just to prove to myself that it can be done. It's actually not a terrible process – I've done worse maintenance on airplanes and lived to tell the tale.

I've also been working on some schematics for the airplane's electrical system. I put together a first draft, along with some notes, and sumbitted it to the Aeroelectric list for review by the learned elders. If you're interested you can cick here to see my current electrical diagrams and some text, including an explanation of how the aux battery will be used.