This morning I got the right aileron installed, which took about half the time that I spent on the other aileron yesterday. That's about typical for these sorts of tasks. Just imagine how fast my next RV will go together.

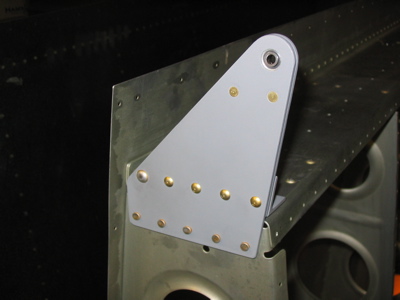

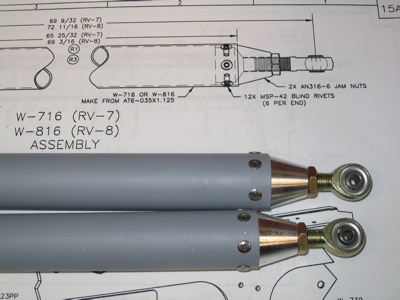

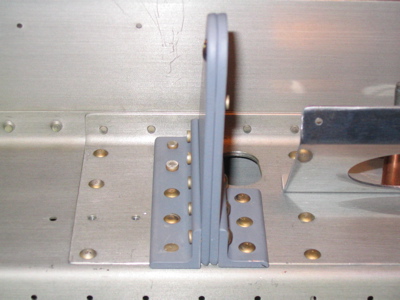

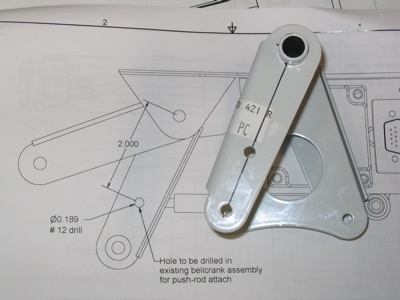

Then I pulled the TruTrak roll servo out of its box and went about installing it in the right wing. The plans included with my servos are specific to the RV-7 install kit, which made it simple to locate the right place to drill the hole for the control arm:

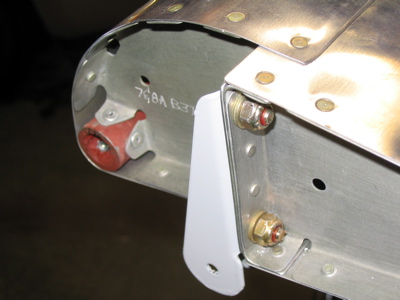

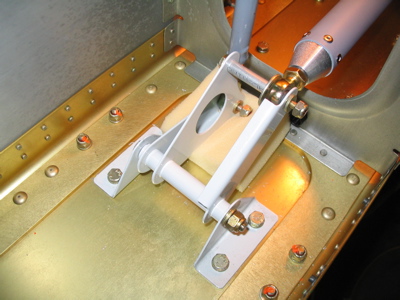

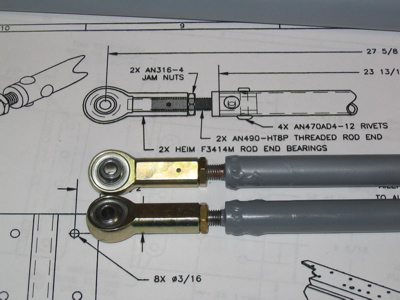

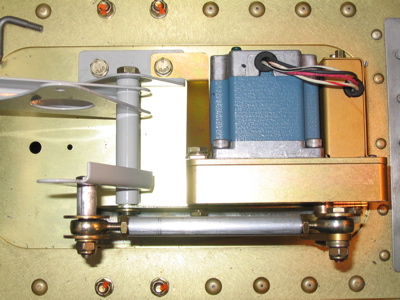

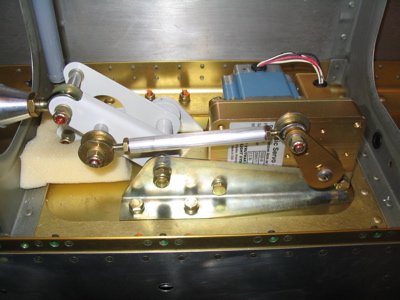

Here's the servo temporarily mounted in its home. The arm on the servo swings the aileron bellcrank by way of a short pushrod. I used AN970 fat washers in more places than is called for in the TruTrak instructions, just to make sure that the autopilot pushrod won't come loose and jam the controls if one of the rod-end bearings comes apart. Preventing jammed controls is a good thing.

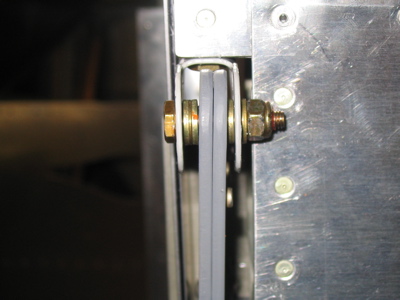

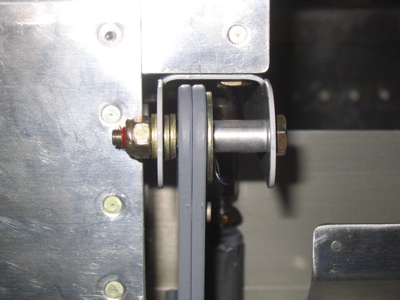

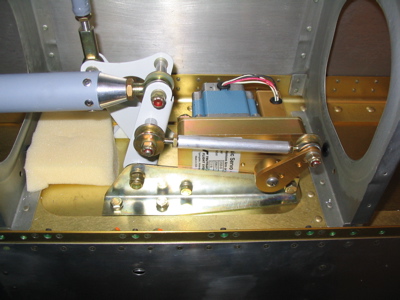

In the photos below, all three pushrods are hooked up. You can see that even at either end of the available range of travel, the servo control arm comes nowhere close to going over-center. Since that could lock up the ailerons if it happened in flight, this is also a good thing.

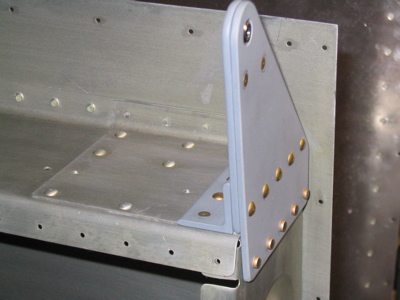

Luckily the servo brackets are anodized, because it was too cold and snowy to prime anything today. Before calling it quits I secured the bolts that go into the tapped holes in the servo with safety wire and Loctite, and lubricated both aileron bellcrank bushings with whatever weight of Aeroshell is in my grease gun (#14, I think) before installing them permanently. I was going to start in on the pitot tube, but the order from Van's I placed last Monday still hasn't arrived, and I was counting on having the angle stock from that order to mount the pitot mast. Oh well.

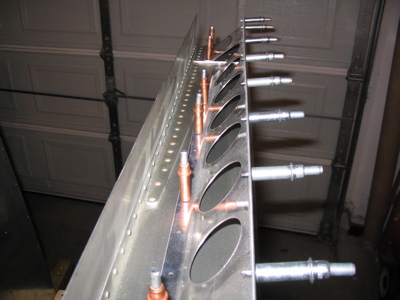

Update: Oops, I realized later today that I have to finish the aileron gap seals before I can permanently mount the ailerons. So, off they came. No big deal, it's only a five minute job to remove them, and not too much more to put them back on now that all the attach hardware and spacers are fitted.

Actually, now that I think about it, there's really no point in permanently attaching the ailerons just yet. The control surfaces can stay in the storeroom until I really need them. Okay, well at least I'll have the aileron gap seals and flap braces to work on while I wait on the next visit from the UPS man.