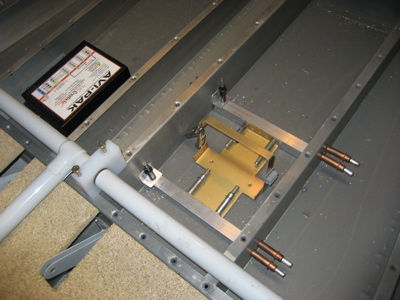

Mary helped me rivet two little brackets to the longeron between the F-708 and F-707 bulkheads. These secure the static line as it runs forward from the tee, and keep it from rubbing on the seatbelt bracket. I know it's probably overkill to use rivets and threaded fasteners here, but I wanted to avoid using those self-adhesive tie wrap mounts because of all the problems I've heard about. Apparently they tend to come unstuck over time, so I'm doing the extra work to make sure my static line will stay put.

Just after the tee, the line transitions from 1/4" ID silicone tube to the 1/4" OD Nylaflow tubing that's standard issue for aircraft pitot/static plumbing. No adapter fitting necessary – I just slipped one tube inside the other for a length of about four inches.

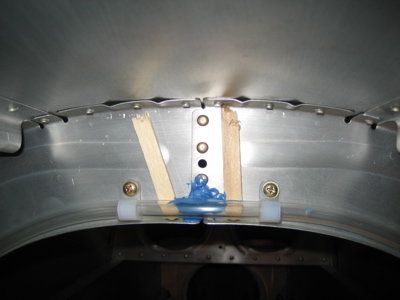

While I was back there I gooped some RTV between the static line and the rivet at the top of F-708. After it cured I removed the popsicle sticks, and now the RTV keeps the rivet from rubbing through the tubing.

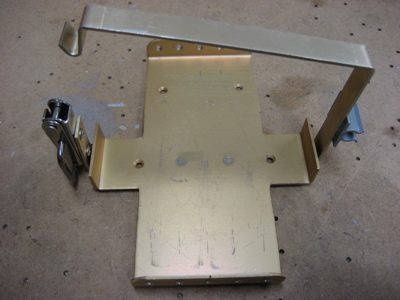

Between F-707 and the F-706 baggage bulkhead, the line angles downward to parallel the F-786B-L stiffener, then disappears through a snap bushing behind the baggage sidewall cover. Two more little angle brackets are pop riveted to the stiffener here to hold the line in place. (The grey blotch is an area that got a shot of primer after I scratched it up a bit.)

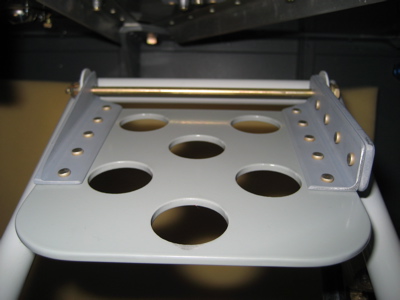

The static line runs forward through snap bushings beneath the baggage sidewall covers, then goes through another snap bushing through the F-705 seat back bulkhead and emerges under the armrest.

This routing for the static line is nonstandard – I got the idea from Dan – but it will make the tubing totally invisible as it travels from the tailcone to the instrument panel. In the baggage area it runs behind cover panels, and in the seating area proper it will be hidden beneath the armrest and behind the interior upholstery. I still need to figure out how to bring it through F-704, but that job will wait for another day.