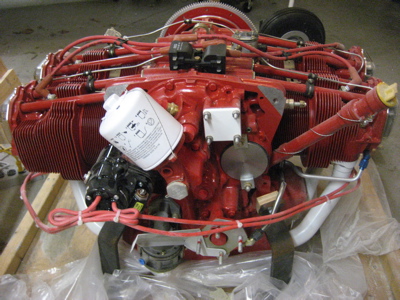

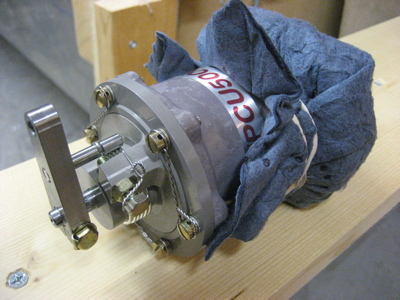

Here's the propeller governor, a PCU500X. This guy is basically an speed-controlled oil pump, which controls the pressure of the oil being pumped through the hollow crankshaft, and thus sets the pitch of the propeller blades to hold the desired RPM. I started to explain this to Mary but she was too distracted to endure another of my lectures about aviation theory, so I just told her "it costs a thousand dollars and makes the airplane go like hell."

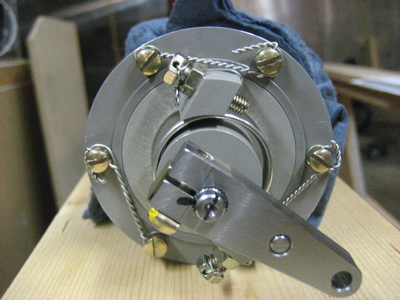

I had to cut off the safety wire, loosen the screws, and rotate the shaft to the correct angle to fit Van's cable bracket. Here it is after I redid the safety wire:

I used my cool new Milbar reversible safety wire pliers to twist the new lockwire, and I must say the improvement in my safety wire workmanship is noticeable compared to when I was using the old, cheap pliers. I guess once again I learn that quality tools make a difference.

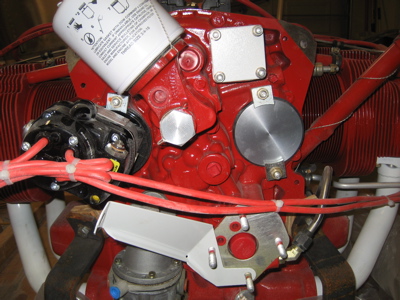

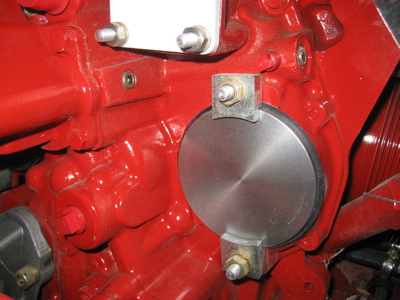

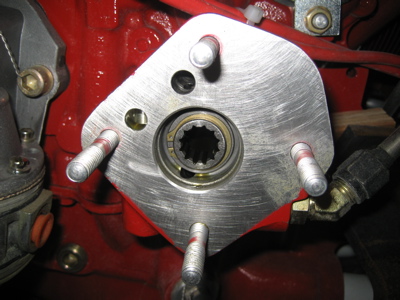

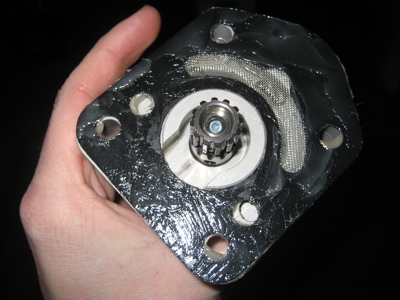

I wiped down the surface of the governor drive pad, and removed the caps covering the drive gear and the oil ports:

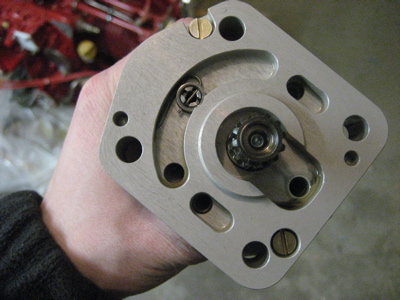

Likewise, I cleaned the mating surface on the governor and removed the plastic plugs from it too. I made sure to take these photos so I don't have to wonder, "did I really remember to remove those plugs before I bolted on the governor?"

The instruction sheet that comes with the governor says to coat both sides of the included gasket with "a suitable release agent". I dithered on this for a while before finding an old RV-List posting mentioning that Van's preferred substance is plain old fuel lube. I guess the idea here is to make it possible to remove the old gasket if you have to remove the governor, and not to put something on there to enhance the quality of the seal (e.g. Permatex).

Then I bolted the governor and cable bracket to the engine, using star washers under the nuts. Due to the clearances involved I had to use a crow's foot on my torque wrench when tightening the nuts, but that was no big deal.

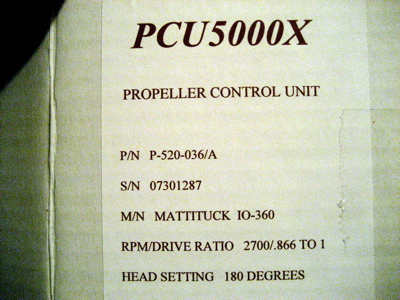

Here's the model info and serial number, in case I ever need it: