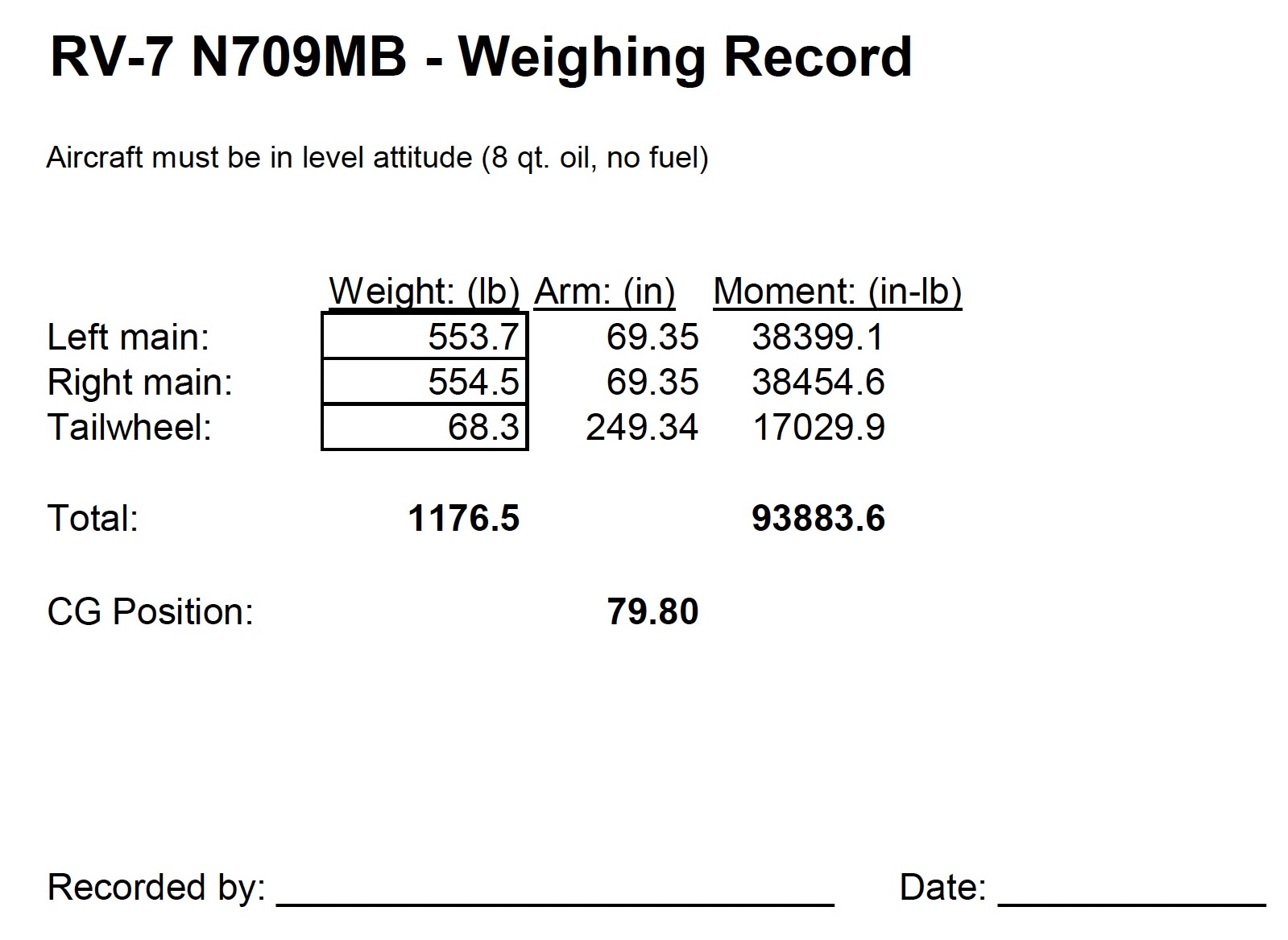

I leveled the airplane and used plumb bobs to mark the location of the wing leading edges and the center points of all the three wheels. From these marks I was able to measure the arm figures for each wheel, to be used later when calculating the CG. The measured locations of the main wheels ended up being within 1/10" of each other, so I just split the difference and recorded them both as the same value.

Purpose-designed aircraft scales are super expensive, but these days you can buy pretty accurate digital scales for not much money. I bought three of these 660 lb scales from Amazon and satisfied myself, by standing on each one in turn, that they were probably accurate:

I made some ramps to help me roll the airplane up onto the scales, by gluing together some thin plywood in a stair-step manner:

I cut these to size and rounded the corners of each step – they actually work pretty well, and were cheap to make:

I installed all the removable pieces of the airplane – cowl, covers, panels, interior, and seats – and rolled the plane onto the scales for an initial weight check. This didn't give me accurate weights for each wheel, but I wanted to double-check the total weight before getting too far along:

Then I leveled the airplane and weighed it again, which gave me a proper weight figure from each wheel. Using the measured positions of each wheel, I made a little spreadsheet to calculate the empty weight and CG position.

The airplane is heavier than I'd hoped, which is not a surprise, but it didn't turn out as heavy as it could have been. In the future I might look at a lightweight lithium battery as an easy way to save ten pounds, and perhaps a future panel makeover – or even a composite propeller – will make it lighter as well. Still, for now I have enough useful load to carry myself, my wife, full fuel, and some luggage, which is really the main goal.

As for the CG position, it ended up pretty far forward, which is a good thing for the RV-7. I calculated various loading scenarios, and the only time the aft CG limit is a concern is if I have two big guys, empty tanks, and a whole lot of baggage – not a common scenario, thankfully.

I have to pull everything apart again for the final inspection, but first I had to take a picture of the airplane in the highest state of put-togetherness that it's ever been so far: