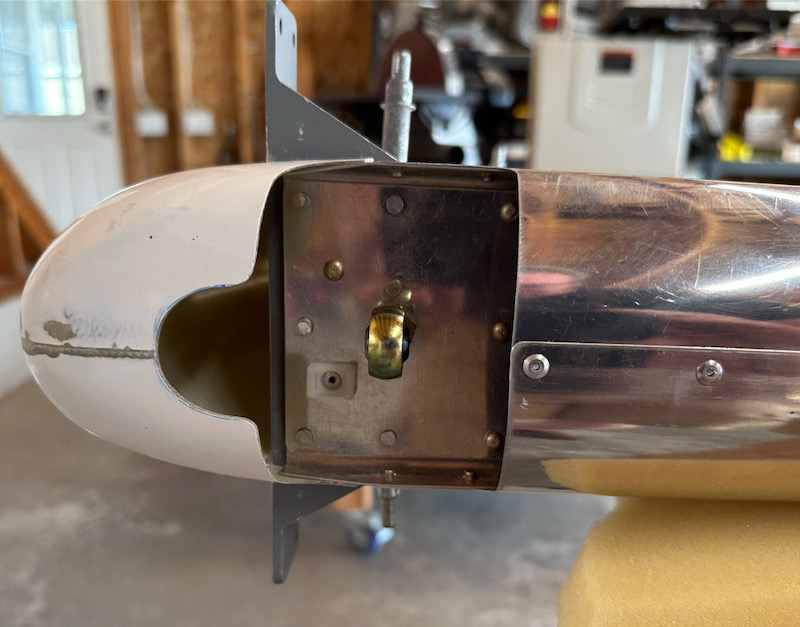

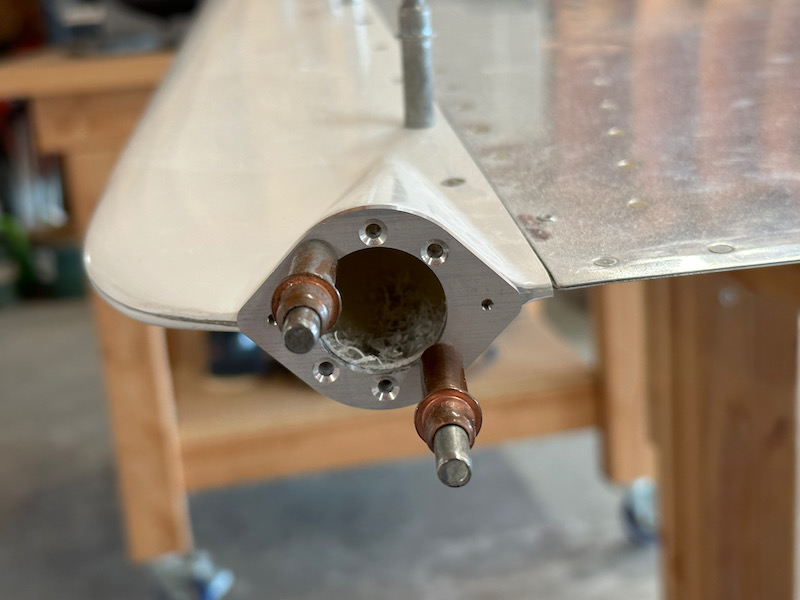

While working on the rudder fit and the vertical stabilizer fairing, I decided to re-check the clearance between the elevators and the horizontal stabilizer tip fairings. I was surprised to find that I had inadequate clearance (less than the minimum 1/8") on the starboard side. Not sure what happened there, perhaps I had the elevator hinge bearings adjusted differently during fitting versus how they are installed now.

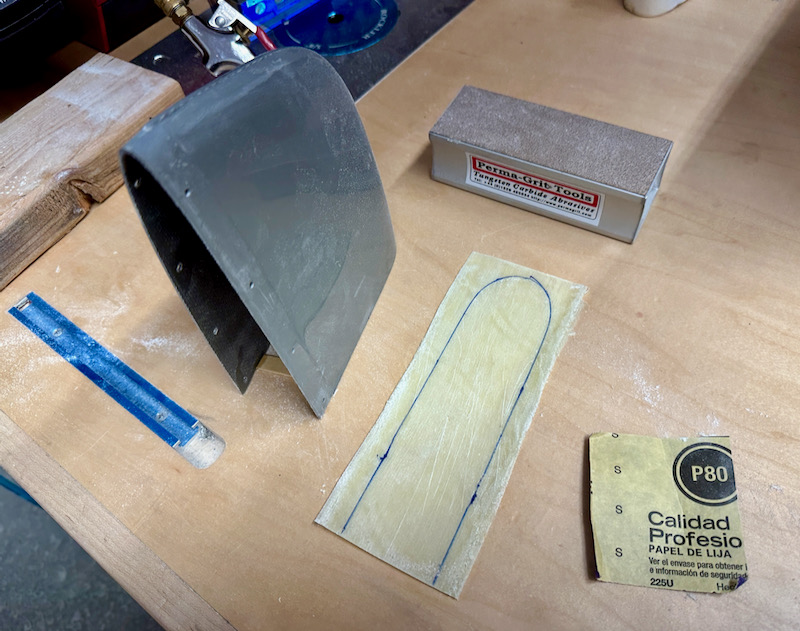

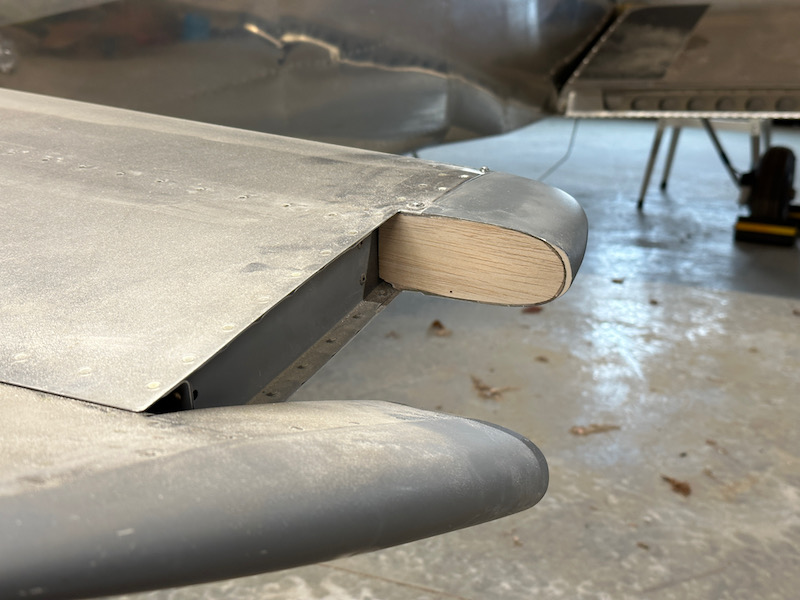

I sanded the fairing to fix the clearance issue, which resulted in me sanding right through the epoxy layer and into the balsa wood underneath. So something needed to be done about that:

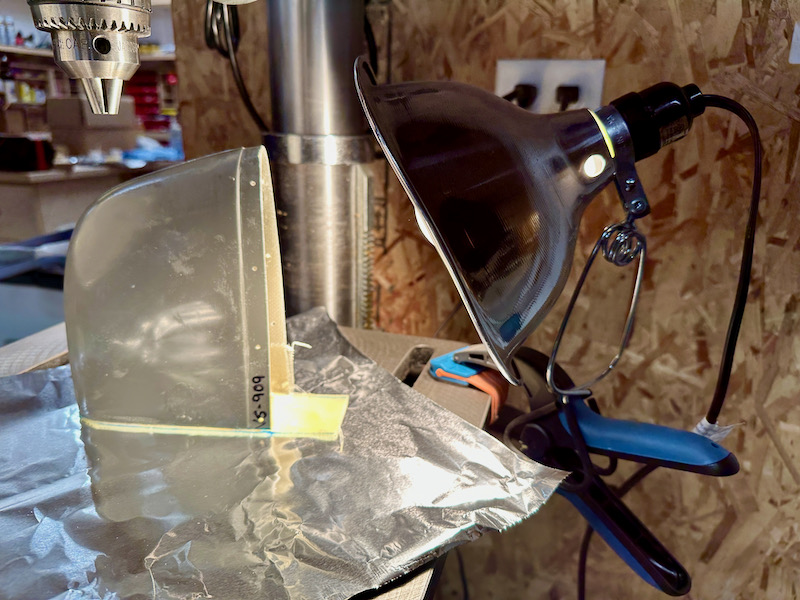

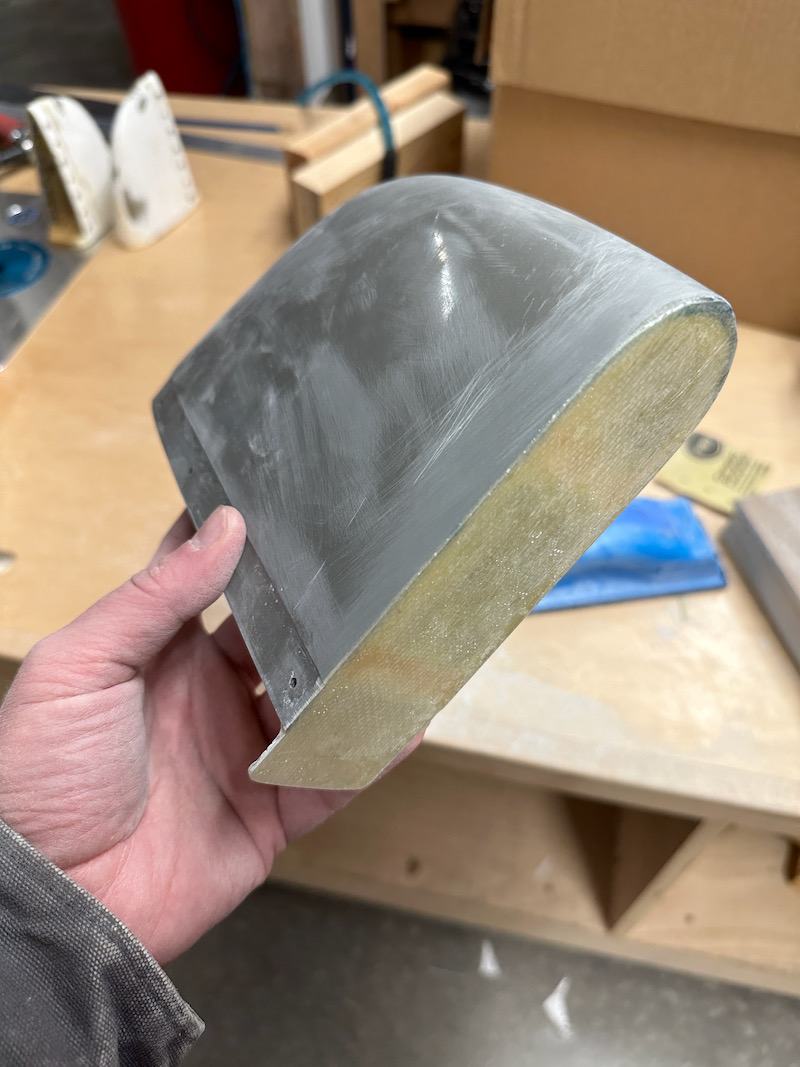

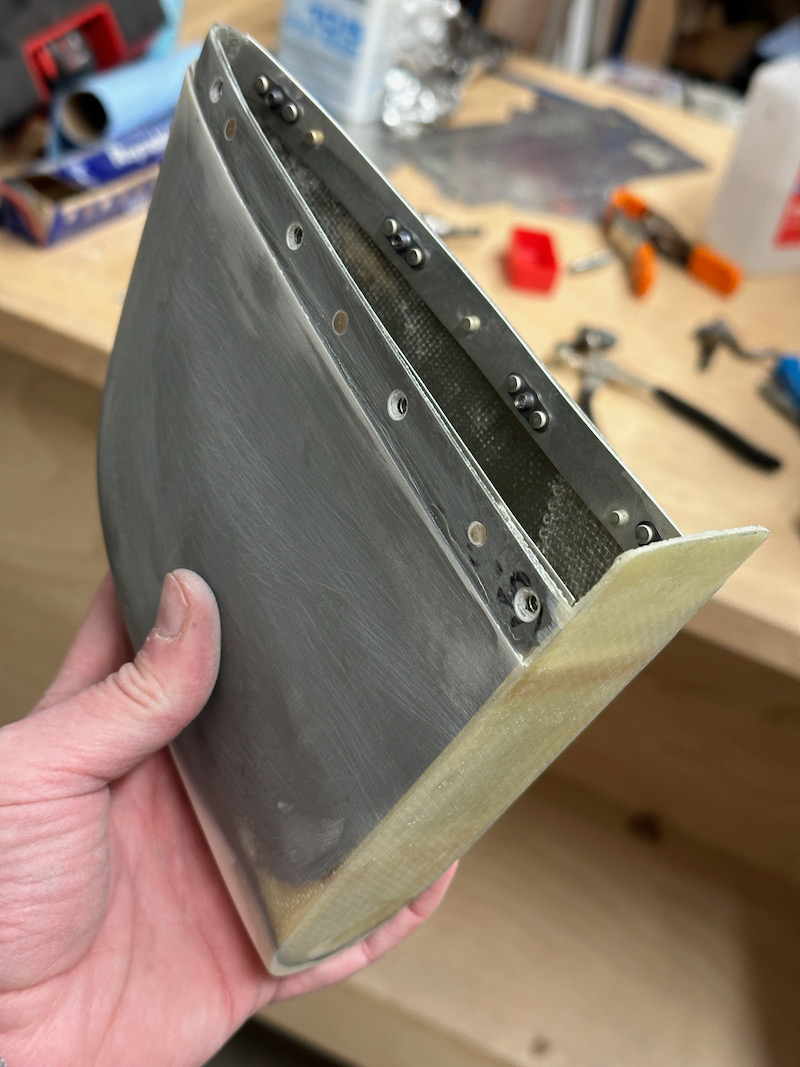

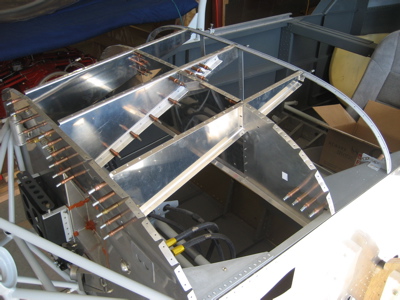

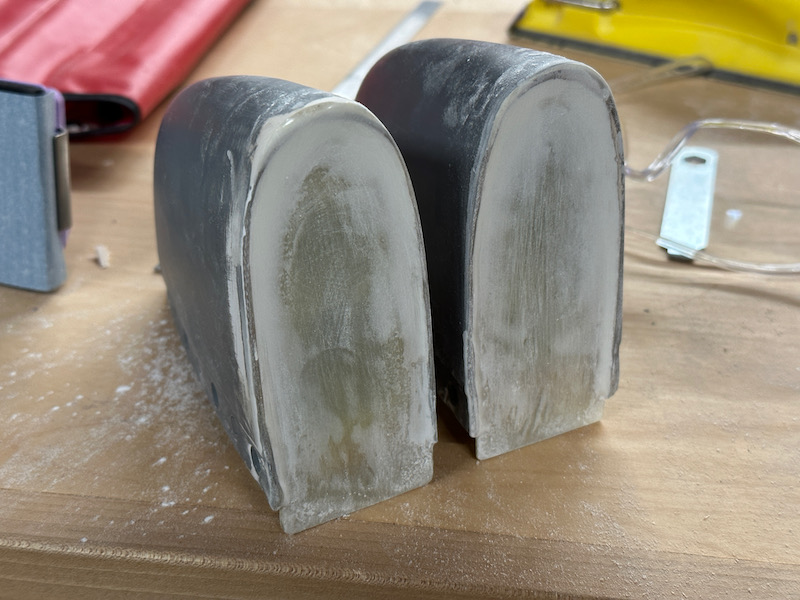

I had been regretting using balsa anyway, so I carved it all out and replaced it with fiberglass just like I did with the vertical stabilizer fairing. Of course I had to do both sides so they'd be identical, otherwise I wouldn't be able to sleep at night. The process here was identical to that used for the VS fairing: popsicle stick supports, glass panel bonded with flox bead, additional glass layer on the inside. I promise it turned out nice even though this in-progress picture makes it look terrible:

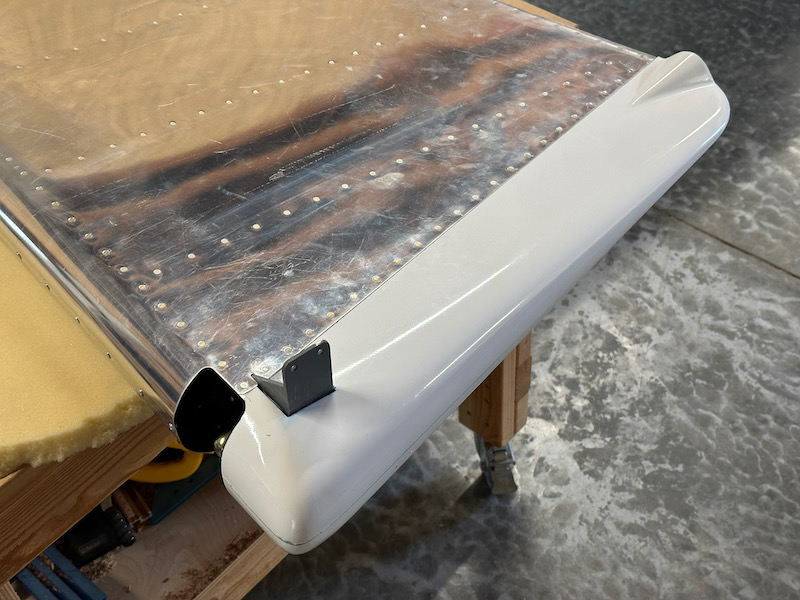

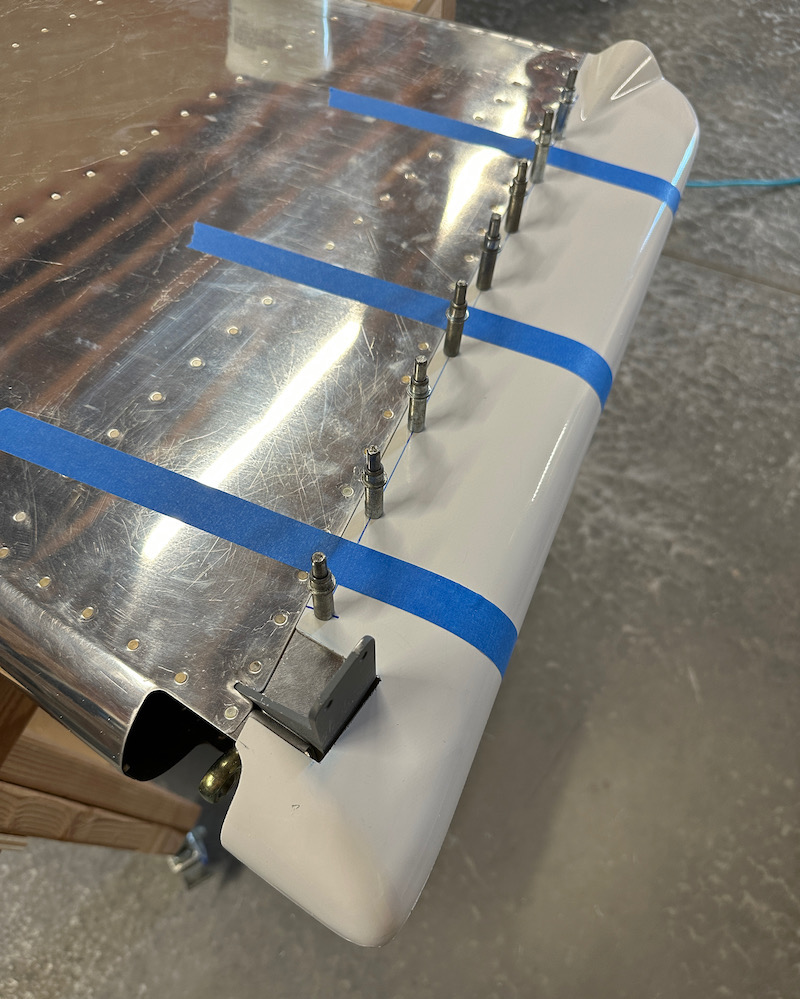

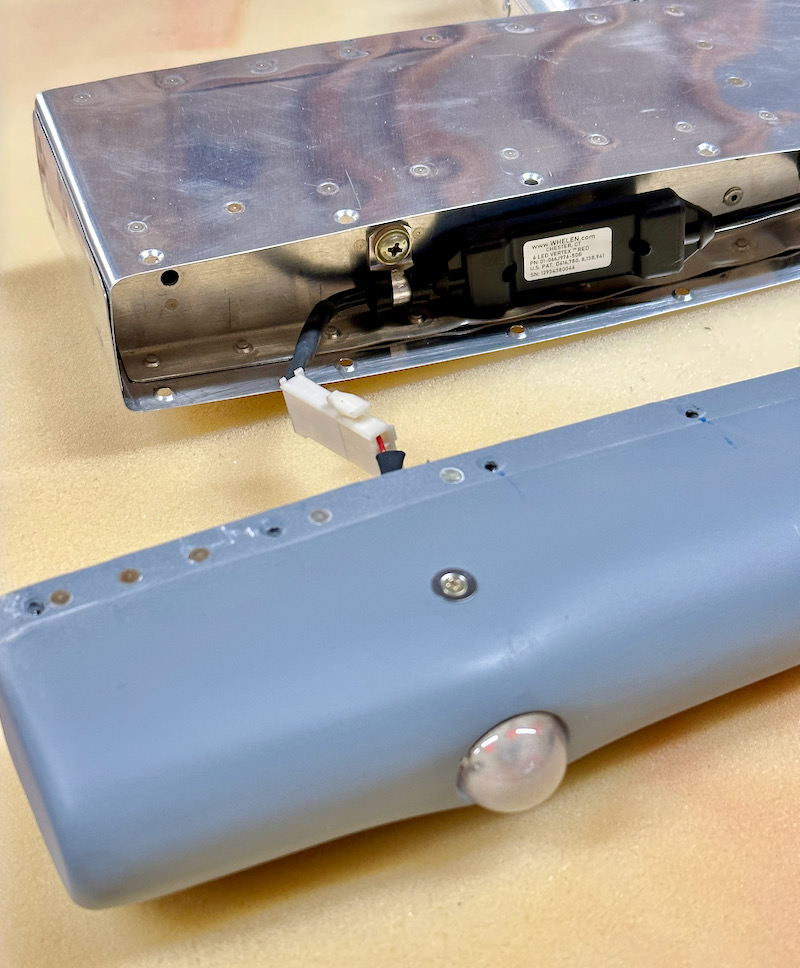

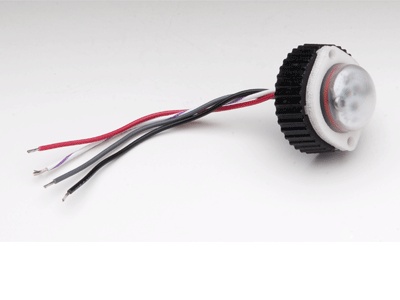

I sprayed all these fairings with several coats of SEM high-build primer, then sanded lightly with 320 grit. I like this stuff – it's expensive but it gives a decent result, and it comes in a handy spray can.

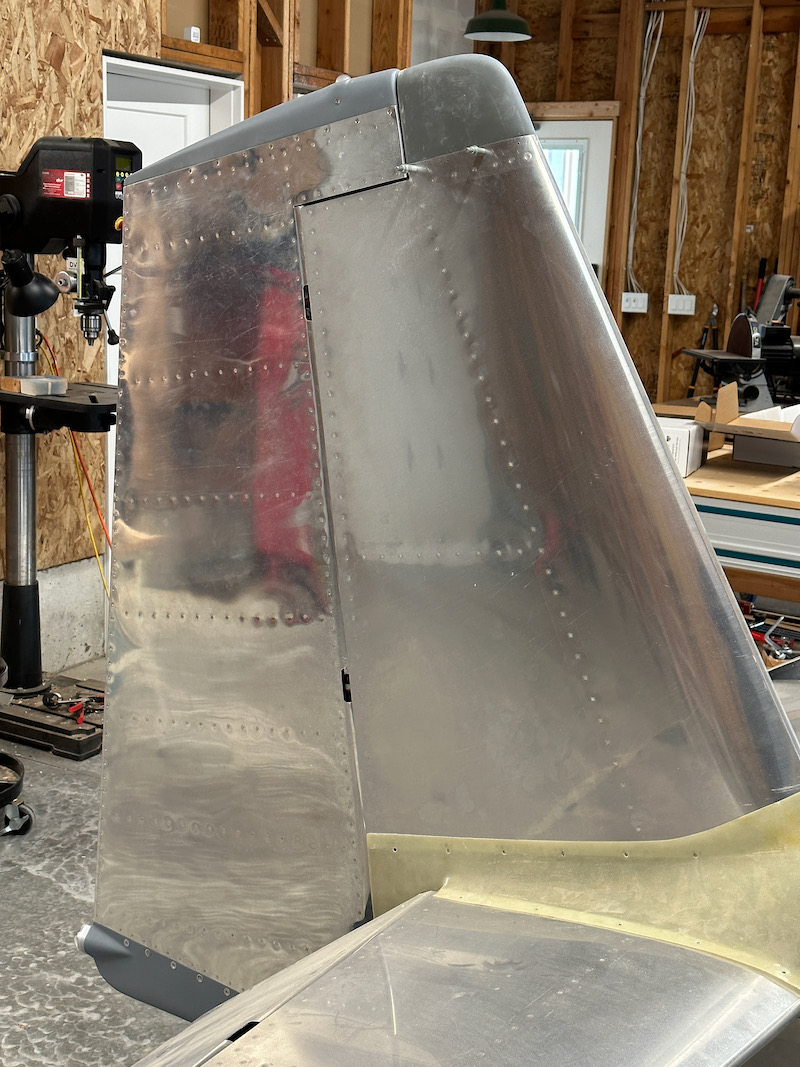

As before, I followed up with a cosmetic coat of 7220 and installed the fairings on the plane. And just as before, the results are not perfect but close enough that I'm happy for now. The pro painter will have a few pinholes to fill, but the shape is correct and the clearance problems are gone:

So now all the fairings on the tail of the airplane are technically done, although I still want to work on improving the fit of the empennage fairing. But that will have to wait for next year's fiberglass season – it's now too cold and rainy for that kind of work.