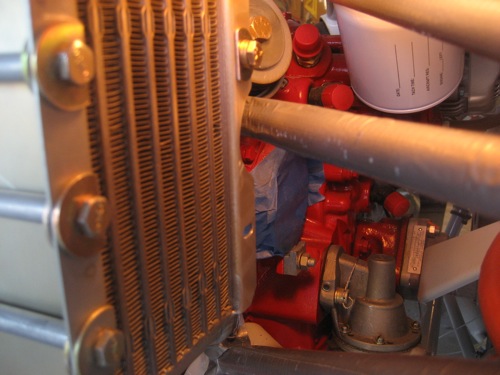

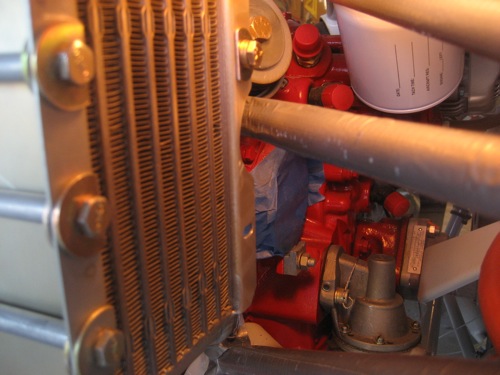

The oil cooler is attached to the baffles behind the #4 cylinder, at the left rear corner of the engine. (I did briefly consider mounting it elsewhere, but I couldn't find a place that it would fit) Unfortunately, the plans are especially vague about exactly where to position the oil cooler on the baffle, leaving you up to your own devices to make it fit. Also, the thin sheet metal baffles are really not strong enough to be hanging an oil cooler from, which is widely known to eventually lead to cracks. Many builders add reinforcement to the baffles to better support the weight of the oil cooler, which is yet another thing you have to design and build on your own. This will be a long post showing how I fit the oil cooler and built up the baffles to support it.

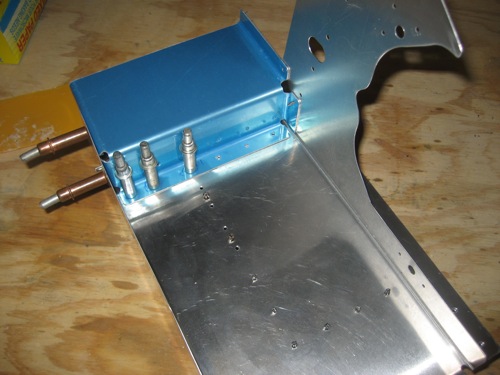

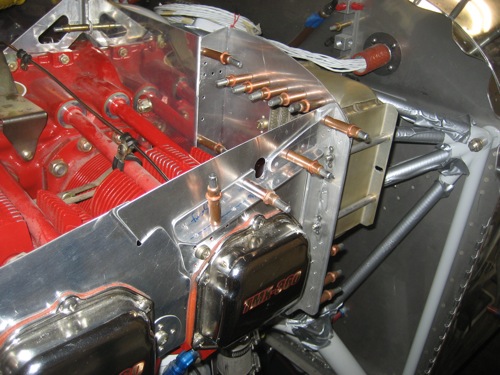

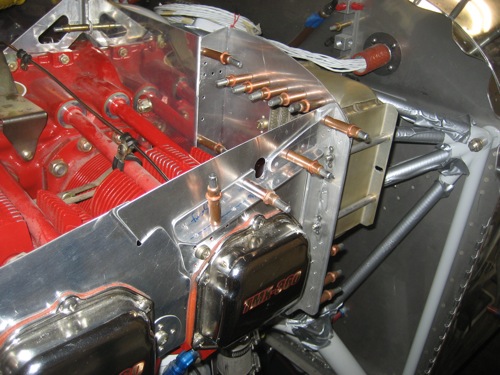

The CB-705B brace is a prepunched part that forms a box at the top of the #4 baffle, and adds some stiffness to it. Its rear flange is supposed to share some rivets in common with the oil cooler doubler ring. They don't give you any guidance on where to position it vertically, but I think this is how they want you to install it: (rear baffle removed for illustration purposes)

The problem with this is that positions the oil cooler so low that almost half of it is blocked by the cylinder fins. For an RV-8 with its narrow cowl this is your only option, but in a side-by-side RV there is room to mount it higher for better cooling airflow.

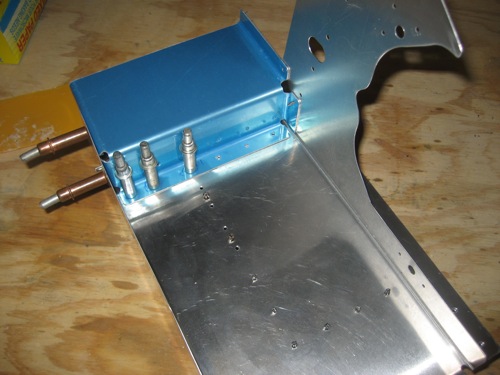

My solution was to cleco the aft flange on CB-705B to the next row of prepunched holes on the oil cooler doubler. This allows the doubler, and thus the oil cooler opening in the baffle, to move upwards a substantial amount.

Obviously the aft flange on CB-705B now blocks an equivalent amount of the oil cooler opening, but there's a solution for that.

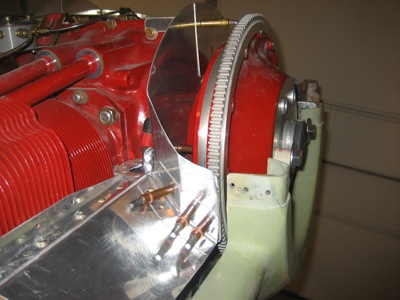

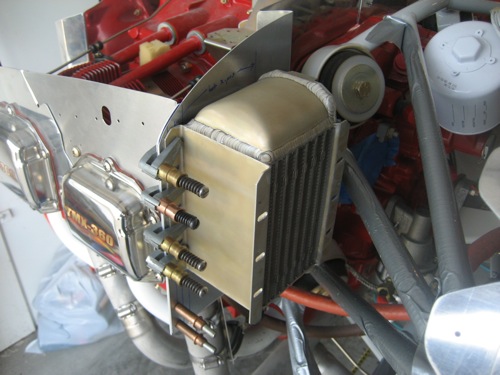

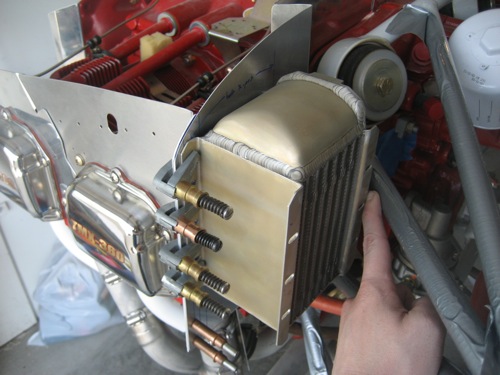

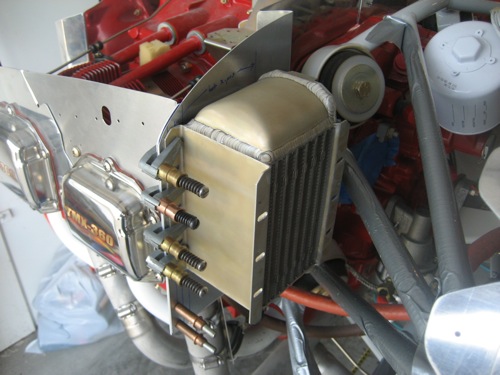

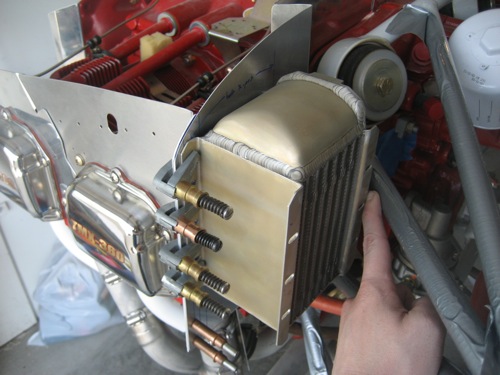

Test-fitting the oil cooler to make sure everything is going to fit. You want to mount it as high as you can to get the most airflow through it, but you don't want it to get so high that it hits the inside of the cowl. There is also a constraint related to the clearance between one of the mounting bolts and the diagonal engine mount tubes. And, you don't want to put the rectangular opening so close to the edge of the baffle that you run into edge distance problems.

It's typical to have to grind away a portion of the flange where my finger is, to get the proper clearance between the oil cooler and the engine mount.

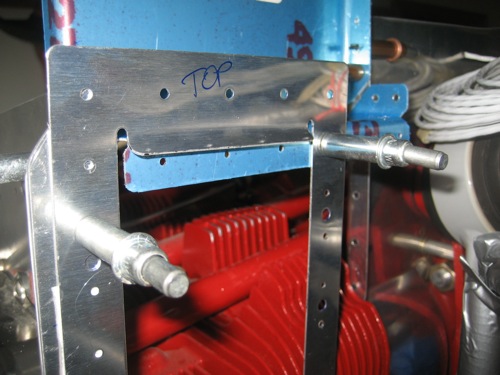

Drilling the doubler to the rear baffle locks in the oil cooler position. The sharp-eyed will noticed that I drilled a hole for a third bolt in the middle of the outboard corner. Since the oil cooler has a hole for a bolt there, I figured why not use it…

The three clecoed holes in the CB-705B flange will be used – the rest of the flange will be cut off.

If you are working on this part of the baffles right now, this photo contains enough information for you to position your CB-705B:

I riveted a piece of 0.040" angle to the top of the horizontal part of CB-705B. It picks up the row of rivet holes along the top of the oil cooler doubler. It's all one big puzzle that you have to figure out how to fit together, while you're also designing the pieces.

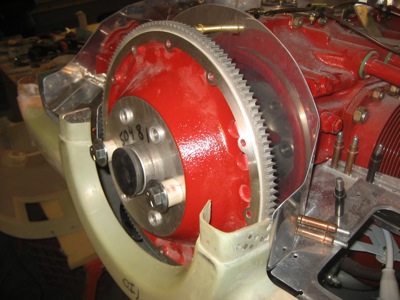

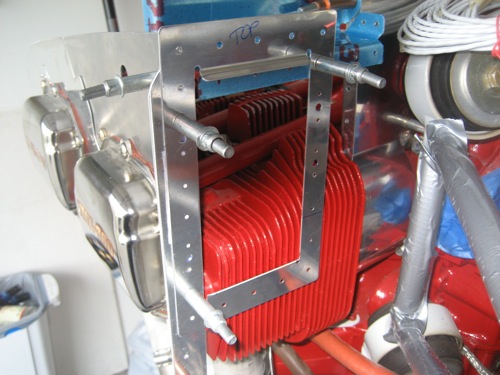

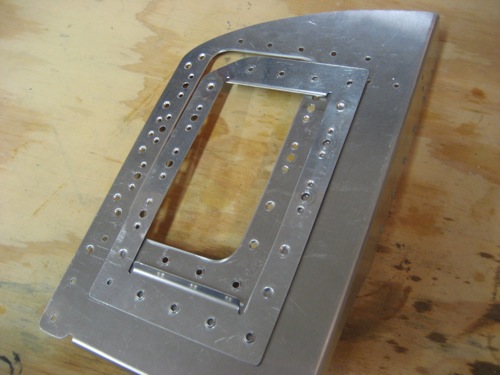

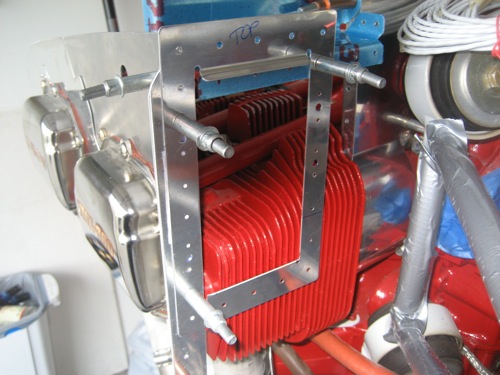

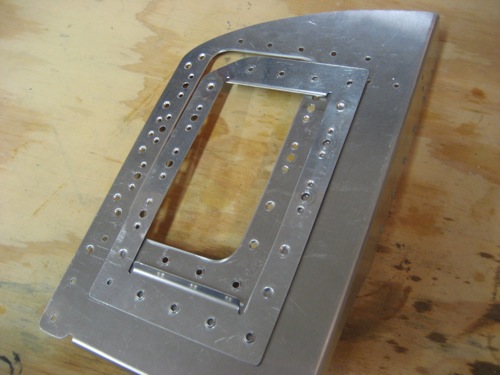

Lots of work between the last photo and this one. I built a number of reinforcement pieces to be attached to the baffles, which I'll detail below. Here's the master shot of all the parts that will be riveted together to form the #4 cylinder baffle and oil cooler mount:

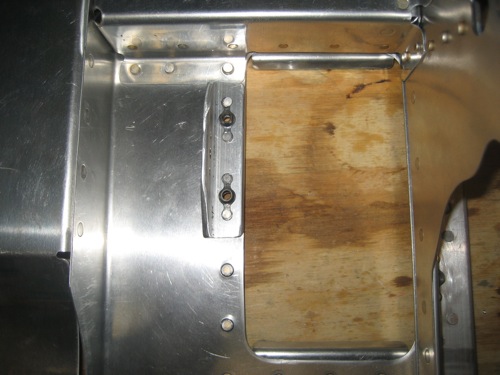

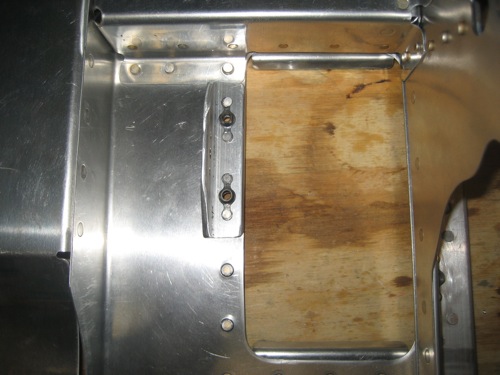

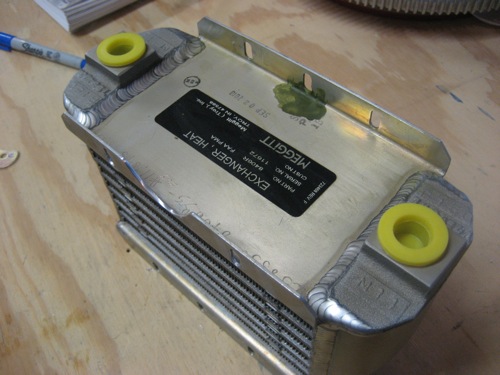

From left to right, this is the aft cylinder baffle, 0.063" spacer, and oil cooler doubler ring. These are all kit parts, no bespoke items yet. Note that the outboard top corner of the doubler ring is substantially ground away to fit the inside of the cowl.

I used a unibit and air nibbler to make the rectangular opening in the aft baffle, using the doubler ring as a template. A complex pattern of dimpling is required to accommodate the different rivets that are flush on one side or the other. The small piece of angle picks up the two inboard bolts on the oil cooler, and will become the attachment point for a diagonal brace later on (a future project).

Another view of the aft baffle and doubler ring. Flush rivet holes everywhere – be careful to pay attention to which way each one faces!

I used a piece of 1/8" angle to stiffen the corner where the aft baffle and outboard side baffles meet. I had to file a radius on the apex of the angle (not visible in this photo) to get it to nest into the bent flange in the corner. The holes where the oil cooler bolts come through are just barely far enough from the angle web to install the nutplates – careful measuring is required here. Note the countersunk holes on the aft side of the 0.063" spacer where it faces the dimpled holes in the aft baffle.

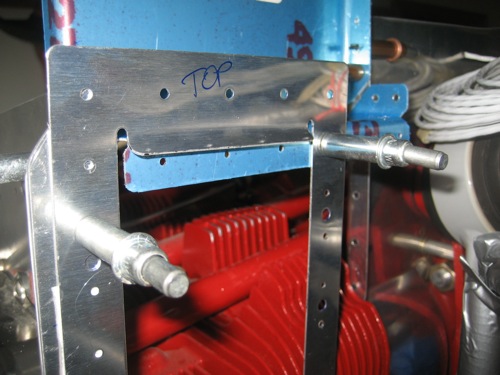

The leftmost and rightmost pieces in this photo are designed to stiffen the side and rear baffles by providing a load path from the oil cooler to the forward mounting screw. This shown more clearly in one of the photos below, keep reading.

This is what 705B looks like after it's trimmed to fit the cowl, and after the bottom flange has been truncated and a new flange riveted to the top. I also added an extra little tab on the left side to tie it into the cylinder baffle.

Here's a final fit test to make sure everything is going to work. It all seems to line up, thank goodness.

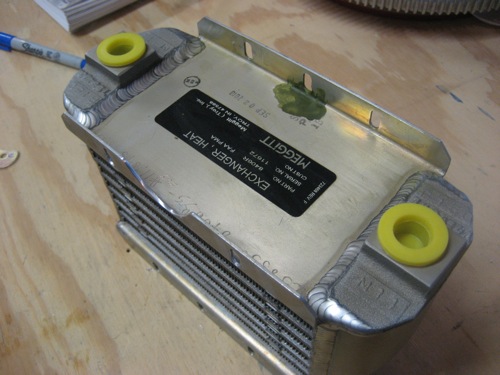

I used a hacksaw, rotary file, and scotchbrite drums to notch the oil cooler flange where it comes close to the engine mount. No clearance problems now, but probably no more warranty either!

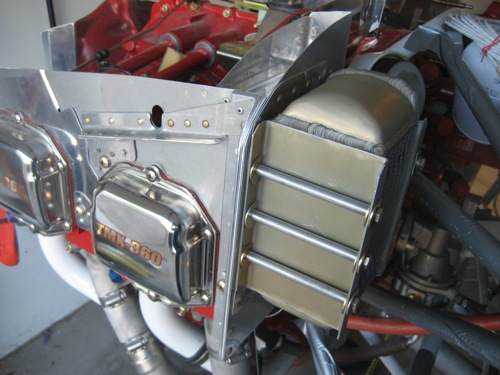

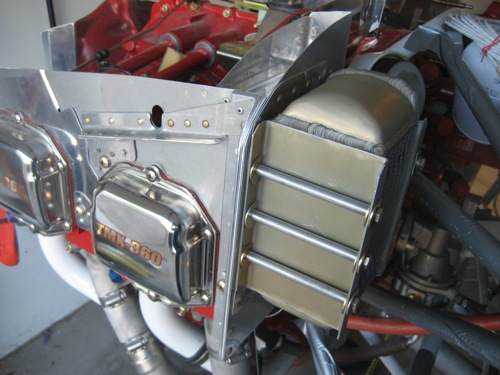

It took hours to rivet the whole thing together. Many of the rivets are hard to get to, and you have to pay careful attention to the order you install things so you don't block access to any of the holes.

Another view from the side:

Here's how the stiffener pieces on the outboard side work:

And a closeup of the triangular, joggled attachment at the aft end. The two blind rivets here are the only ones in the entire #4 cylinder baffle, believe it or not – I managed to squeeze or buck all the rest.

Top view:

A view from the inside. Note how the horizontal part of CB-705B is even with the top of the oil cooler opening. That turned out pretty well – not sure why Van's didn't just design the part that way.

Nutplates on the corner stiffener. Some of these rivets were an absolute pain to set properly. It wasn't my best or prettiest riveting work, but it's adequate.

Back side, showing the doubler ring. Rivets are flush where the oil cooler flanges go.

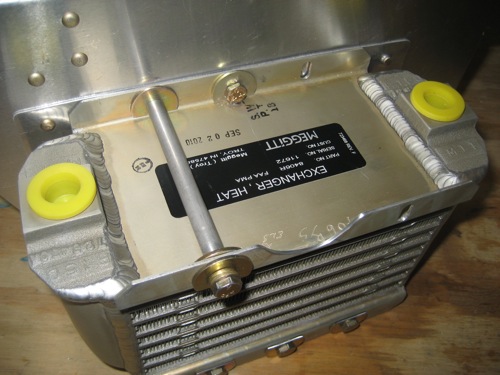

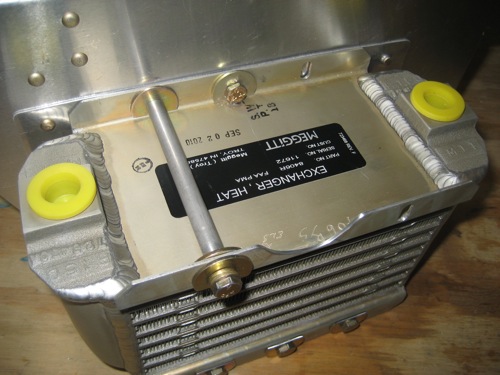

Test-fitting the oil cooler to the completed baffles. I cut and ground a bunch of AN970 large-area washers to spread the load on the cooler flanges, which are made of some very soft type of aluminum and don't seem very strong. Later on I'll prime and paint the steel washers to keep them from rusting where I cut through the cad plating.

I turned some spacers on my lathe to fit around the bolts and prevent the oil cooler flanges from bending.

The inboard side has one long bolt (with spacer) and one short bolt where the rear flange was ground away. The lower hole doesn't get a bolt since the cylinder fin would be in the way on the forward side.

Believe it or not, it's possible to install and remove this whole huge thing with the oil cooler still attached. With the baffle screwed into the cylinder head, the oil cooler mounting is very solid.

Plenty of clearance between the inboard flange and the engine mount – the plans call for a minimum of 1/2", and I have between 5/8" and 3/4".

Mounting the oil cooler up high allows more of the face to be exposed to the local airflow, which should help with oil temperatures in the summer.

The only part of the oil cooler mounting arrangement that's not as stiff as I'd like is the inboard side, which flops around a bit when shaken. This is only natural, since there's no good way to attach anything to the cylinder between the case and the head. Later on I'll rectify this by running a brace from the flange on the inboard side of the oil cooler to a convenient screw on the cylinder head.

I dabbed a bit of zinc chromate on an area of the oil cooler where I lightly gouged it while trying to fit the short bolt on the inboard side. Got to protect this expensive and vital piece of machinery.

That's it for the oil cooler mounting, for now anyway. A friend once told me, "Keep adding stiffness to the baffles until you can attach a chain and tow the airplane around by the oil cooler." While it may not be quite that strong, it's definitely a lot better than if I'd stuck with the flimsy factory design. Hopefully by putting in the extra effort now, I'll have saved myself some heartburn down the road.